Page 181 - CW E-Magazine (21-1-2025)

P. 181

Carbon Foot Print Carbon Foot Print

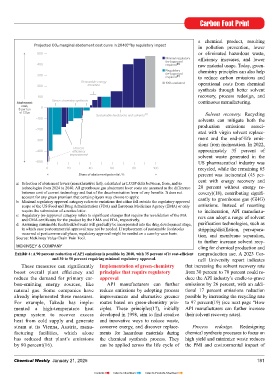

Decarbonization strategies for synthetic API Renewable energy transition Projected CO marginal abatement cost curve in 2040, by regulatory impact a chemical product, resulting

[a]

3 Share or total emissions reduction Strategy setup 500 in pollution prevention, lower

or eliminated hazardous waste,

[a]

Slightly costly NPV positive Independent Minimal Minimal regulatory effi ciency increases, and lower

levers focusing 400 (re-)approval

[b]

required

on renewable- raw material usage. Today, green-

energy transition Regulatory chemistry principles can also help

300 (re-)approval

[c]

required to reduce carbon emissions and

Renewable-energy 10% unabated

Cost Supplier Regulatory 200 transition operational costs from chemical

approval synthesis through better solvent

100 recovery, process redesign, and

Green-chemistry synthesis

Abatement continuous manufacturing.

cost,

Cost per ton of CO 5–10% ~10% not reduced $ per ton 0

~$–25 to $–75 NPV negative Dependent Required of CO

e Sustainable feedstocks and solvents [d] Solvent recovery. Recycling

–100 solvents can mitigate both the

API manufacturers can achieve an emissions reduction of 5 to 10 percent by transitioning to renewable-power and -fuel

sources, though this shift may incur slightly higher costs than the previously mentioned levers. production emissions associ-

–200

ated with virgin solvent replace-

Source of ment and the end-of-life emis-

addressed ~10% ~80% ~10% –300

emissions sions from incineration. In 2022,

Process

Cooling Heating Electricity –400 eciency approximately 35 percent of

improvement

Examples n Switch to green electricity in all production steps solvent waste generated in the

of solutions n Switch to renewable fuels (eg, biomass, biogas) for heat and steam generation –500 US pharmaceutical industry was

60

40

Decarbonization strategies for synthetic API Sustainable feedstocks and solvents 0 20 Share of abatement potential, % 80 100 recycled, while the remaining 65

percent was incinerated (45 per-

4 Share or total emissions reduction Strategy setup a: Selection of abatement levers (nonexhaustive list); calculated as LCOP delta between, from, and to cent with energy recovery and

[a]

Sustainable ~50% NPV positive Independent Minimal technologies from 2024 to 2040. All greenhouse gas abatement lever costs are assumed as the difference 20 percent without energy re-

feedstocks between cost of current technology and that of the decarbonization lever of any benefi ts. It does not covery)(18), contributing signifi -

and solvents account for any green premium that certain players may choose to apply.

requiring b: Minimal regulatory approval category refers to variations that either fall outside the regulatory approval cantly to greenhouse gas (GHG)

supply chain emissions. Instead of resorting

collaboration scope of the US Food and Drug Administration (FDA) and European Medicines Agency (EMA) or only

require the submission of a notice letter.

Cost Supplier Regulatory c: Regulatory (re-)approval category refers to signifi cant changes that require the revalidation of the MA to incineration, API manufactu-

(re-)approval rers can adopt a range of solvent

and CMA certifi cates for the product by the EMA and FDA, respectively.

d: Assuming sustainable feedstock/solvents will gradually be incorporated into the drug development stage, purifi cation technologies, such as

in which case postcommercial approval may not be needed. If replacement of sustainable feedstocks stripping/distillation, pervapora-

occurred at postcommercial phase, regulatory approval might be needed on a case-by-case basis.

Cost per ton of CO ~10% not reduced Source: McKinsey Value Chain Twin Tool. tion, and membrane separation,

~$–100 to $–300 NPV negative Dependent Required to further increase solvent recy-

MCKINSEY & COMPANY cling for chemical production and

API manufacturers can potentially achieve a substantial emissions reduction, around 50 percent, by collaborating with suppliers Exhibit 4: A 90 percent reduction of API emissions is possible by 2040, with 35 percent of it cost-effi cient nonproduction use. A 2023 Cor-

to reduce their carbon-emitting energy use and adopt sustainable feedstocks and solvents, though this lever comes at a high

cost and faces supply chain challenges. and 30 to 50 percent requiring minimal regulatory approval. nell University report indicates

These measures can signifi cantly Implementation of green-chemistry that increasing the solvent recovery rate

Source of boost overall plant effi ciency and principles that require regulatory from 30 percent to 70 percent could re-

addressed ~50% ~50%

emissions reduce the demand for primary car- approval duce the API industry’s cradle-to-grave

Feedstocks Solvents bon-emitting energy sources, like API manufacturers can further emissions by 26 percent, with an addi-

Examples n Adopt sustainable feedstock in new API development/manufacturing natural gas. Some companies have reduce emissions by adopting process tional 17 percent emissions reduction

[b]

of solutions n Adopt green solvents with high recyclability and low carbon impacts already implemented these measures. improvements and alternative greener possible by increasing the recycling rate

n Implement sustainability criteria during raw material procurement For example, Takeda has imple- routes based on green-chemistry prin- to 97 percent(19) (see next page “How

Note: Emissions baseline and sources based on average API manufacturing profi le from public databases (eg, CDP or companies’ sustainability mented a high-temperature heat ciples. These principles(17), initially API manufacturers can further increase

reports).

Decarbonization levers and cost analyses sourced from McKinsey Decarbonization Lever Library and industry expert inputs. pump system to recover excess developed in 1998, aim to fi nd creative their solvent recovery rates).

a: Net present value. heat from cold supply and generate and innovative ways to reduce waste,

b: Via carbon capture and storage; e-crackers; bio-based materials. steam at its Vienna, Austria, manu- conserve energy, and discover replace- Process redesign. Redesigning

Source: McKinsey Catalyst Zero; McKinsey Decarbonization Lever Library.

facturing facilities, which alone ments for hazardous materials during chemical synthesis processes to focus on

MCKINSEY & COMPANY has reduced that plant’s emissions the chemical synthesis process. They high yield and minimize waste reduces

Exhibit 3: Decarbonization strategies for synthetic API manufacturers vary but could produce a 90 percent reduction by 2040. by 90 percent(16). can be applied across the life cycle of the PMI and environmental impact of

180 Chemical Weekly January 21, 2025 Chemical Weekly January 21, 2025 181

Contents Index to Advertisers Index to Products Advertised