Page 178 - CW E-Magazine (21-1-2025)

P. 178

Carbon Foot Print

A challenging path to decarboniza- major challenge for API manufacturers and supply chain challenges, parti-

tion to pinpoint the EF source of incoming cularly for smaller API manufacturers.

Despite the urgent need for decar- materials and accurately calculate their Finally, regulatory requirements arise

bonization, API manufacturers face Scope 3 emissions. Also, the sector when modifi cations to existing pro-

two primary obstacles in their path lacks standardized measurement and duction lines and processes necessitate

to net zero: lack of visibility into a reporting protocols for product carbon additional fi lings and approvals.

given product’s emissions and limited footprints (PCFs), which hinders trans-

transparency into solutions and their parency between API suppliers and A decarbonization pathway for API

implications. their pharmaceutical customers. manufacturers

Based on our comprehensive

Lack of product-level carbon Limited transparency of decarboni- assessment of available and emerging

visibility zation solutions and their implica- decarbonization technologies, we

The complex and resource-inten- tions estimate that API manufacturers can

sive nature of the API synthesis process Some API manufacturers are based reduce approximately 90 percent of their

makes it diffi cult to accurately convert in regions where environmental regu- total emissions by 2040 (the most am-

material usage and energy consumption lations are generally less stringent and bitious net-zero target year set by large

data into carbon emissions. This con- there is limited awareness of available pharma and healthcare organizations)

version involves applying knowledge decarbonization technologies and their by leveraging a combination of decar-

of life cycle assessment/carbon foot- implications. Most API companies also bonization levers (Exhibit 3). These

print (LCA/CF) tools and carefully typically operate with smaller profi t levers are listed below in order of

selecting EFs, which can vary signifi - margins compared with pharmaceuti- abatement cost (Exhibit 4) and consist

cantly based on manufacturing methods, cal companies(15), often leading them of varying levels of regulatory require-

process effi ciency, and regional energy to prioritize short-term fi nancial returns ments and supplier dependence. Some

sources. For instance, the EF for ace- over the up-front investments required of them offer immediate opportunities

tonitrile, a commonly used solvent in for decarbonization. The adoption of for emission reductions, while others

API synthesis, ranges from 1.5 to 12.5 kg green feedstocks and solvents, which will likely require more time, invest-

of CO per kg of solvent globally is crucial for achieving net-zero emis- ment, and supplier collaboration to

2

(Exhibit 2). That wide range poses a sions, presents signifi cant procurement become viable.

[a]

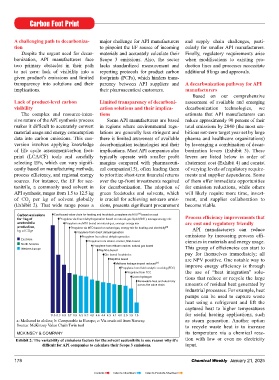

Carbon emissions tCoal-based value chain for heating and feedstock, propylene via MTO based on coal

for 1 kg of tPropylene via direct dehydrogenation based on natural-gas liquid (NGL), average energy mix Process effi ciency improvements that

acetonitrile tPropylene via MTO based on natural gas, average energy mix are cost and regulatory friendly

production, tPropylene via MTO based on natural gas, energy mix for heating and electricity [b]

kg of COe tPropylene from direct dehydrogenation API manufacturers can reduce

tPropylene from direct dehydrogenation emissions by increasing process effi -

East Asia tPropylene from ethane cracker, NGL based ciencies in materials and energy usage.

North America tPropylene from ethane cracker, natural gas based

Western Europe tNaphtha based This group of effi ciencies can start to

tBio-based feedstocks pay for themselves immediately; all

tNaphtha based are NPV positive. One notable way to

tMethane leakage impact reduced [c] improve energy effi ciency is through

tPropylene from uid catalytic cracking (FCC)

tPropylene from FCC the use of “heat integration” solu-

tGreen hydrogen tions that reduce or recycle the large

tRenewable heat and electricity

across the value chain amounts of residual heat generated by

industrial processes. For example, heat

pumps can be used to capture waste

heat using a refrigerant and lift the

captured heat to higher temperatures

12.5 8.3 6.9 5.7 5.5 5.3 5.2 4.8 4.6 4.4 4.3 4.1 4.0 3.9 3.5 1.5 for useful heating applications, such

a: Methanol to olefi ns; b: Comparable to Europe; c: Via crude oil from Norway. as steam generation. Another option

Source: McKinsey Value Chain Twin tool to recycle waste heat is to increase

MCKINSEY & COMPANY its temperature via a chemical reac-

Exhibit 2: The variability of emissions factors for the solvent acetonitrile is one reason why it’s tion with low or even no electricity

di ffi cult for API companies to calculate their Scope 3 emissions. input.

178 Chemical Weekly January 21, 2025

Contents Index to Advertisers Index to Products Advertised