Page 176 - CW E-Magazine (21-1-2025)

P. 176

Carbon Foot Print Carbon Foot Print

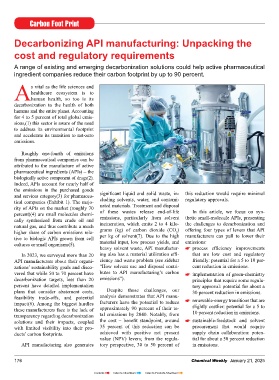

Decarbonizing API manufacturing: Unpacking the Annual CO output in 2014, % of total by segment

[a]

cost and regulatory requirements Global [a] Life sciences and Pharmaceuticals Purchased

[b]

[d]

[c]

and chemicals

goods

healthcare

Life sciences 4.4

A range of existing and emerging decarbonization solutions could help active pharmaceutical and healthcare Pharmaceuticals 20

ingredient companies reduce their carbon footprint by up to 90 percent. and chemicals

Purchased 49 APIs 47

s vital as the life sciences and Other supply goods

healthcare ecosystem is to chains (eg, food 24

Ahuman health, so too is its and catering)

decarbonization to the health of both Nonmedical

humans and the entire planet. Accounting Others 95.6 equipment 8 Excipients 11

for 4 to 5 percent of total global emis- Medical equipment 10 Other upstream Scope 3 18

(eg, capital goods)

sions,(1) this sector is aware of the need

to address its environmental footprint Personal travel 10 Scope 3 downstream 6 Packaging

and accelerate its transition to net-zero Scope 1 and 2 (eg, use of sold products) materials 32

emissions. (eg, healthcare Scope 2 (eg, purchased 16

electricity, steam,

facilities and owned 28 heat, and cooling)

Roughly one-fourth of emissions eet, anesthetics, Scope 1 (eg, Process

building energy)

from pharmaceutical companies can be direct emissions) 11 chemicals 10

attributed to the manufacture of active

gigatons ~45

pharmaceutical ingredients (APIs) – the COe output, ~2 ~0.4 ~0.2

biologically active component of drugs(2).

Indeed, APIs account for nearly half of a: Global healthcare emissions accounts for 43 countries with estimated total emissions of ~2.0 Gt CO e in 2014, based on World Input-Output data-

2

base and PRIMAP database.

the emissions in the purchased goods b: Triangulated based on UK National Health Service data.

and services category(3) for pharmaceu- signifi cant liquid and solid waste, in- this reduction would require minimal c: Pharmaceutical and chemical companies’ emissions profi les are averaged based on ~40 relevant players from CDP database.

tical companies (Exhibit 1). The majo- cluding solvents, water, and contami- regulatory approvals. d: Purchased goods category emissions profi les based on spend-based emissions factors (EF), where API EF is 0.54 kg CO e/$, excipient EF is 1.8 kg

2

CO e/$, process chemicals is 1.1 kg CO e/$, and packaging materials (including plastics, metal, glass, rubber, and paper) EF is 1.5-6.0 kg CO e/$.

rity of APIs on the market (roughly 70 nated materials. Treatment and disposal Source: Arup’s Healthcare climate footprint; CDP; Science Based Target Initiative 2

2

2

percent)(4) are small molecules chemi- of these wastes release end-of-life In this article, we focus on syn-

cally synthesized from crude oil and emissions, particularly from solvent thetic small-molecule APIs, presenting MCKINSEY & COMPANY

natural gas, and thus contribute a much incineration, which emits 2 to 4 kilo- the challenges to decarbonization and

higher share of carbon emissions rela- grams (kg) of carbon dioxide (CO ) offering four types of levers that API Exhibit 1: Within the life sciences and healthcare ecosystem, API manufacturing stands out as a major contributor of carbon emissions.

2

tive to biologic APIs grown from cell per kg of solvent(7). Due to the high manufacturers can pull to lower their API manufacturing is critical to the feedstock specialty and fi ne chemicals Services(13), have pledged to achieve

cultures or small organisms(5). material input, low process yields, and emissions:

heavy solvent waste, API manufactur- process effi ciency improvements life science industry’s decarboniza- upstream(10). net zero across their respective supply

In 2023, we surveyed more than 20 ing also has a material utilization effi - that are low cost and regulatory tion goals chains by as soon as 2040 and no later

API manufacturers about their organi- ciency and waste problem (see sidebar friendly: potential for a 5 to 10 per- API manufacturing is a complex, API manufacturers are facing than 2050.

zations’ sustainability goals and disco- “How solvent use and disposal contri- cent reduction in emissions. multistep process involving numerous increasing pressure from their down-

vered that while 50 to 70 percent have butes to API manufacturing’s carbon implementation of green-chemistry chemicals, solvents, and other materi- stream stakeholders – including Already, collaborations among

decarbonization targets, less than 20 emissions”). principles that require some regula- als. The average process material inten- biopharma companies, wholesalers, global pharmaceutical companies and

percent have detailed implementation tory approval: potential for about a sity (PMI)(8) ranges from 70 to 433 kg distributors, and healthcare facili- API suppliers are accelerating the decar-

plans that consider abatement costs, Despite those challenges, our 30 percent reduction in emissions. of materials per kg of API produced(9). ties – to decarbonize. Indeed, many bonization of the life sciences industry.

feasibility trade-offs, and potential analysis demonstrates that API manu- renewable-energy transitions that are Also, typical yields are between 30 and stakeholders across the healthcare For instance, initiatives like the Activate

impact(6). Among the biggest hurdles facturers have the potential to reduce slightly costlier: potential for a 5 to 60 percent for small-molecule synthesis value chain have made commitments program, launched by six of the world’s

these manufacturers face is the lack of approximately 90 percent of their to- 10 percent reduction in emissions. from raw materials and as low as 5 to to aggressive Scope 1, 2, and 3 emis- leading pharmaceutical companies, are

transparency regarding decarbonization tal emissions by 2040. Notably, from 10 percent for more intricate syntheses. sions reductions. For example, eight of actively engaging API suppliers across

solutions and their impacts, coupled the cost – benefi t standpoint, around sustainable-feedstock and solvent These intensive material inputs lead to the ten leading pharma companies(11), 20 countries(14). This program aims to

with limited visibility into their pro- 35 percent of this reduction can be procurement that would require a substantial environmental footprint: and even major healthcare agencies help suppliers measure, report, and re-

ducts’ carbon footprints. achieved with positive net present supply chain collaboration: poten- API emission factors (EFs) range from and systems, like the US Department duce their emissions through capability

value (NPV) levers; from the regula- tial for about a 50 percent reduction 50 to 1,000 kg of CO per kg of API – of Health and Human Services(12) and building and facilitating access to green-

2

API manufacturing also generates tory perspective, 30 to 50 percent of in emissions. two to 50 times greater than that of the the United Kingdom’s National Health fi nancing options.

176 Chemical Weekly January 21, 2025 Chemical Weekly January 21, 2025 177

Contents Index to Advertisers Index to Products Advertised