Page 182 - CW E-Magazine (21-1-2025)

P. 182

Carbon Foot Print Carbon Foot Print

How solvent use and disposal contributes to API manufacturing’s carbon emissions

How API manufacturers can further increase their solvent recovery rates

The process material intensity reveals that 50 to 60 percent of these percent of cradle-to-gate emissions

API manufacturers can signifi cantly this goal by following a structured qua- offering a promising path toward a

(PMI) for API manufacturing varies emissions originate from solvent (exhibit). boost their environmental and eco- lity assurance approach that includes more sustainable future.

widely, from 70 to 433 kilograms (kg) production (“cradle to gate”); the nomic performance while increasing establishing specifi cations, characteri-

of materials per kg of API produced, de- remainder stem from downstream Gate to grave. Despite the availabi- solvent recovery rates. This strategy zing impurities, conducting a risk Enhancing solvent recycling capa-

pending on the development phase,[a] waste disposal, including recycling lity of on-site distillation units for sol- focuses on the following: assessment, and verifying through city

with solvents accounting for 50 to 60 and incineration. vent recycling, only about 35 percent of batch analysis. Solvent recycling rates vary signi-

percent of the total mass.[b] The high solvent waste is currently recycled for ensuring solvent quality through fi cantly, from 10 to 95 percent across

PMI associated with solvents translates Cradle to gate. Solvent production internal use or external reclamation(d). rigorous controls. Engaging customers on the benefi ts facilities and regions, with a median

to 40 to 50 percent emissions of API’s involves signifi cant emissions from The rest is incinerated, releasing 2 to engaging with customers about the of recycled solvents rate of about 58 percent in Asia.[c] Cur-

carbon footprint.[c] petrochemical feedstock production 4 kg of CO per kg of solvent, signifi - benefi ts of recycled solvents. The production of APIs is customer rently, API manufacturers rely prima-

2

and solvent synthesis, with the latter cantly higher than the emissions from

Life cycle emissions analysis accounting for approximately 80 recycled solvents.[e] enhancing recycling capabilities by centric, requiring transparent com- rily on mature and cost-effi cient solvent

investing in advanced technologies . munication and approval from custo- technologies like distillation to recover

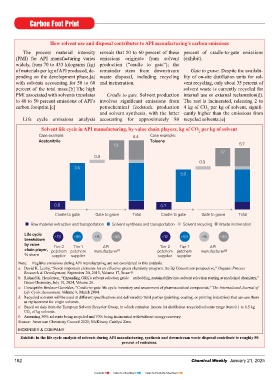

Solvent life cycle in API manufacturing, by value chain players, kg of CO per kg of solvent mers when using recycled solvents. By the high-value and easily recyclable

2

Case example: 6.4 Case example: Ensuring the high quality of adopting the product carbon footprint solvents, like tetrahydrofuran, toluene,

Acetonitrile Toluene recycled solvents (PCF) assessment, API manufacturers and acetonitrile.

1.8 5.7 In line with the WHO’s Good can signifi cantly demonstrate the green-

1.7 Manufacturing Practices guidelines,[a] house gas reductions achieved through To increase these rates, API manu-

0.3 solvents can be recovered and reused recycled solvents. This approach could facturers could invest in advanced

0.3

3.5 during API manufacturing. This is help gain customer approval and solvent recycling technologies like

contingent on the recovery procedures attract new customers, particularly as pervaporation and membrane separa-

3.0

being documented, controlled, and sustainability becomes more critical in tion. Such investments would increase

monitored to ensure that the recovered procurement processes. Using recycled recycling rates and reduce dependence

solvents meet specifi cations and stan- solvents could reduce “cradle to grave” on fossil-based energy recovery

dards (such as more than 99.5 percent emissions by 30 to 50 percent com- methods, a necessary step in the indus-

purity). API manufacturers can achieve pared with using virgin solvents,[b] try’s journey toward a greener future.

0.8 0.7

Cradle to gate Gate to grave Total Cradle to gate Gate to grave Total a: “Q7 good manufacturing practice guidance for active pharmaceutical ingredients: Guidance for industry,” US Food and Drug Administration,

September 2016.

b: Based on McKinsey analysis on carbon footprints for gabapentin synthesis with/without solvent recycling.

Raw material extraction and transportation Solvent synthesis and transportation Solvent recycling Waste incineration c: Based on McKinsey POBOS (pharmaceutical operations benchmarking of solids) database; solvent recycling may include energy recovery from

on-site incineration.

Life cycle ~13 ~55 ~5 ~28 ~12 ~53 ~5 ~30

breakdown APIs. Pharmaceutical company Lupin of 34 APIs produced via chemical and fi nished products are continuously ex-

by value Tier 2 Tier 1 API Tier 2 Tier 1 API

chain player, petchem petchem manufacturer [f] petchem petchem manufacturer [f] has demonstrated this by adopting fermentation routes and found out that tracted. This system has been explored

% share supplier supplier supplier supplier green-chemistry principles: it stream- fermentation routes had a 35 times lower for both small- and large-molecule APIs

Note: Fugitive emissions during API manufacturing are not considered in this analysis. lined the manufacturing of 14 APIs, cut- carbon footprint(22). and has demonstrated operational cost

a: David K. Leahy, “Seven important elements for an effective green chemistry program: An IQ Consortium perspective,” Organic Process ting solvent and reagent consumption by However, transitioning to biologi- savings of 10 to 40 percent(23). These

Research & Development, September 20, 2013, Volume 17, Issue 9. 61 percent and reducing synthesis steps cal routes requires careful assessment. savings stem from the smaller physical

b: Richard K. Henderson, “Expanding GSK’s solvent selection guide – embedding sustainability into solvent selection starting at medicinal chemistry,” by 33 percent(20). footprint of continuous systems, more

Green Chemistry, July 10, 2024, Volume 26. Manufacturers must consider applicabi- effi cient use of materials, and greater

c: Conceptión Jiménez-González, “Cradle-to-gate life cycle inventory and assessment of pharmaceutical compounds,” The International Journal of lity, broader environmental impacts (like

Life Cycle Assessment, Volume 9, March 2004. Thanks to advancements in biotech- wastewater generation), and cost impli- utilization of production capacity, all

d: Recycled solvents will be used at different specifi cations and delivered to third parties (painting, coating, or printing industries) that can use them nology, biologic synthesis (biocatalysis cations. of which could contribute to GHG

as replacement for virgin solvents. and fermentation) offers an alternative to emissions reductions.

e: Based on data from the European Solvent Recycler Group, in which emission factors for distillation-recycled solvents range from 0.1 to 0.5 kg traditional chemical synthesis for some Continuous manufacturing. API

CO of kg solvents.

2

f: Assuming 30% solvents being recycled and 70% being incinerated with/without energy recovery. small-molecule APIs (anti-infective manufacturers can enhance operational Changes to existing commercial

Source: American Chemistry Council 2021; McKinsey Catalyst Zero. agents). This shift decreases reliance on effi ciency by transitioning from tradi- processes, however, will likely require

fossil fuels and energy during manu- tional batch production to continuous regulatory approval. The approval pro-

MCKINSEY & COMPANY

facturing. A 2024 literature review con- manufacturing. In continuous manufac- cess can indeed be time-consuming for

Exhibit: In the life cycle analysis of solvents during API manufacturing, synthesis and downstream waste disposal contribute to roughly 80 ducted by the Technical University of turing, fl ow reactors steadily introduce API manufacturers, as it may take seve-

percent of emissions.

Denmark(21) evaluated the sustainability raw materials into a process train while ral months or years to prepare for the

182 Chemical Weekly January 21, 2025 Chemical Weekly January 21, 2025 183

Contents Index to Advertisers Index to Products Advertised