Page 177 - CW E-Magazine (24-12-2024)

P. 177

8th Global Summit on Process Safety Special Report

The statistics seem to support these on the sidelines of the event, Mr. Rama-

trends. According to a recent Marsh bhadran, admitted that the challenges Credit profi le of carbon black players to remain

report, 43% of incidents can be attri- facing the small and medium (SMEs) comfortable, despite large capex plans

buted to mechanical or asset integrity, chemical manufacturers in India are very

which could be linked to aging assets. different from that of large companies, ndia Ratings and Research (Ind-Ra) grown at a CAGR of around 8% from 6-9% sales volume growth rate in

At the same time, demographic changes and will need appropriate approaches has published the fourth edition of FY21. The robust domestic end-use India’s auto sector in FY25. Carbon black

for some industries, such as retirement and solutions. Iits Chemical Insights report cover- demand, high-capacity utilisations, in- accounts for 20-25% of the total weight

rates as high as 40% of experienced ing the carbon black sector. The report creasing application of specialty carbon of tyres and around 80% of the domestic

workers in the next 3-5 years, can dss+ is addressing this challenge contains the key domestic demand drivers, black and export opportunities available carbon black end-use demand. Domestic

reduce capability to run and maintain by rephrasing the problem to the identi- supply pipeline, company-wise capacity have prompted the large incremental tyre production increased at an average

safe operations. fi cation of top-risks and the critical mix, domestic export and import trends, capacity announcements. Ind-Ra expects of around 5% per annum over FY18-

Mr. Surana controls needed to tackle each of them. global fundamentals, and domestic and the specialty carbon black capacity as a FY23.

added, will stem from their increas- Even as the lost time injury rates in “We are asking them to address these international price trends. proportion of the domestic capacity to

ing complexity, and the transient work the process industries have fallen and controls to ensure that they will work increase to around 32% by FY28 from Furthermore, the increase in adop-

force employed. improvements in overall safety perfor- effi ciently when needed. More and more “The domestic carbon black sector around 11% in FY24. tion of electric vehicles is expected to

mance is evident, spikes in fatalities companies are responding favourably to is expected to see large incremental capa- support carbon black demand, consider-

Mr. Surana also noted that an and major releases continue to occur. this approach.” city additions by FY28 that would in- Sector participants are looking to ing the enhanced reinforcement re-

objective assessment of safety culture “Though there is an awareness of risks crease capacities by 30% over the FY24 increase the share of specialty carbon quired due to the additional torque from

maturity in the organisation is lacking and controls, there is lack of alignment Mr. Ramabhadran also noted that levels. The comfortable credit profi le of black in the sales mix to increase their electric motors. The remaining domes-

in India. “It is a tough job to create a on the big risks and appropriate con- owner-driven companies are responsive sector participants, robust auto demand margins, considering the higher value- tic consumption is supported by indus-

sense of vulnerability without scaring trols,” he noted.“We cannot operate as to the reasoning that process safety and that would provide tailwinds to tyre added nature of product. Specialty carbon tries including plastics, toner & print-

the staff.” we did in the past.” reliability go hand-in-hand, and that production, strong export fundamen- black is typically used in fi bres, semicon- ing inks, coatings, lithium-ion batteries

there is a strong business case for in- tals, increase in demand from applica- ductor cables, engineering plastics, inks, and textiles. The growth of e-commerce

Ageing of assets and demographic Mr. Ramabhadran called upon vesting in safety. He also stressed the tions other than tyre have supported the and other specialised applications. in India has resulted in the increasing

changes – twin challenges senior management to visibly demon- need to create a conducive environment capex announcements. Furthermore, use of packaging materials, further

Mr. Srinivasan Ramabhadran, Man- strate commitment to process safety of reporting and added that while every sector participants are looking to in- The domestic carbon black industry supporting carbon black demand.

aging Director, Asia Pacifi c, dss+, a down the organisation, and called for company seems to have the right intent, crease the proportion of specialty is fairly consolidated with the top fi ve

company spun-off from DuPont Safety independent verifi cation of critical this needs to progress to commitment. carbon black capacities by FY28 to players accounting for around 80% of India to remain net exporter over

Resources, pointed to the ageing of risks and controls. The consultancy, which now has about improve the margin profi le and reduce India’s capacity. Ind-Ra expects these FY25-FY26

assets in the oil & gas, refi ning and 150 experts in India, is scaling up and its volatility. Margins in 2QFY25 are players to retain their market position Ind-Ra expects the incremental pro-

petrochemical industries, as well as of Challenges facing SMEs expects to double head-count in the higher than the median levels witnessed by FY28. duction post ramp-up of the planned

the work force in these industries. Later speaking to Chemical Weekly next two years. over the past 30 quarters. While there domestic capacity additions over

14 key elements of Process Safety Management (PSM) programmes could be some moderation or amomen- Robust domestic demand supports FY25-FY28 to increase the exportable

Element Description tary margin volatility that could last capacity additions surplus and keep India a net exporter

1 Process Safety Information Employers must develop written safety information before conducting a Process Hazard Analysis. for a couple of quarters, the strong Domestic carbon black consump- over this period.

2 Process Hazard Analysis Employers must identify, evaluate, and control hazardous processes. balance sheets of sector participants tion is heavily dependent on the auto-

3 Operating Procedures Employers must develop and implement written operating procedures. would ensure that their fi nancial profi le motive sector since it is a critical India’s carbon black exports shot

4 Incident Investigation Thorough investigations must be completed anytime there is an incident associated to the process. remains comfortable despite the planned component in manufacturing tyres as up in FY24 to 319-ktpa, 42% higher

5 Management of Change Changes to a process must be evaluated to determine if there will be any impacts on the health and safety capex,”says Siddharth Rego, Associate it imparts durability to rubber and pro- y-o-y and 74% higher than the decadal

of employees. Director, Corporate Ratings, Ind-Ra. longs its service life. Ind-Ra expects a average; India has benefi tted from the

6 Mechanical Integrity Process equipment must be designed and installed correctly.

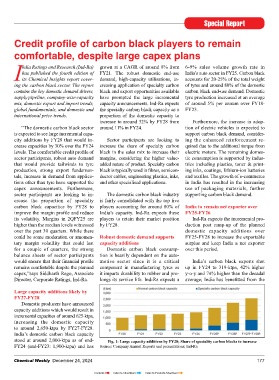

7 Employee Participation The employer must involve workers in PSM programs. Large capacity additions likely by

8 Trade Secrets Employers must provide all information necessary to comply with PSM standards, regardless of the trade FY27-FY28

secret status of the information. Domestic producers have announced

9 Compliance Audits Audits must be conducted and reported at reasonable intervals. capacity additions which would result in

10 Training Employers must train employees on hazards and procedures. incremental capacities of around 625-ktpa,

11 Contractors All contractors working on or near highly hazardous chemicals must be trained on emergency procedures increasing the domestic capacity

and other relevant aspects of the PSM programme. to around 2,650-ktpa by FY27-FY28.

12 Hot Work Hot work permits must be issued for any hot work operations taking place near the process. India’s domestic carbon black capacity

13 Pre-Startup Safety Review (PSSR) The PSSR must be conducted for new and modifi ed facilities before operations can begin. stood at around 2,000-ktpa as of end-

14 Emergency Planning and Response Employees must be trained on emergency planning and response procedures. Fig. 1: Large capacity additions by FY28; Share of speciality carbon blacks to increase

FY24 (end-FY23: 1,900-ktpa) and has Source: Company Annual Reports and presentations; Ind-Ra

176 Chemical Weekly December 24, 2024 Chemical Weekly December 24, 2024 177

Contents Index to Advertisers Index to Products Advertised