Page 191 - CW E-Magazine (3-12-2024)

P. 191

Special Report

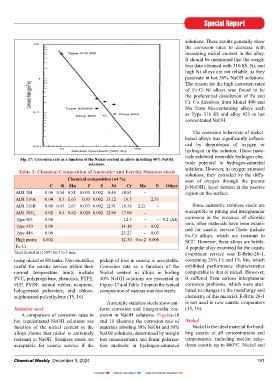

solutions. These results generally show

the corrosion rates to decrease with

increasing nickel content in the alloy.

It should be mentioned that the weight

loss data obtained with 310 SS, Ni, and

high Ni alloys are not reliable, as they

passivate in hot 50% NaOH solutions.

The reason for the high corrosion rates

of Fe-Cr-Ni alloys was found to be

the preferential dissolution of Fe and

Cr. Cu dissolves from Monel 400 and

Mo from Mo-containing alloys such

as Type 316 SS and alloy 825 in hot

concentrated NaOH.

The corrosion behaviour of nickel-

based alloys was significantly influen-

ced by thepresence of oxygen or

hydrogen in the solution. These mate-

rials exhibited reversible hydrogen elec-

Fig. 17: Corrosion rate as a function of the Nickel content in alloys in boiling 40% NaOH

solutions. trode potential in hydrogen-saturated

Table 3: Chemical Composition of Austentic and Ferritic Stainless steels solutions. However, in oxygen saturated

a

solutions, they corroded by the diffu-

Chemical composition (wt %) sion of oxygen through the porous

C Si Mn P S Ni Cr Mo N Other β-Ni(OH) layer formed in the passive

2

AISI 304 0.06 0.54 0.81 0.031 0.002 8.48 18.91 – region on the surface.

AISI 316A 0.04 0.5 1.63 0.03 0.002 13.12 16.5 2.35

AISI 316B 0.06 0.45 1.67 0.033 0.002 12.91 16.58 2.21 – Since austenitic stainless steels are

AISI 305J 0.02 0.4 0.82 0.029 0.002 12.96 17.08 – susceptible to pitting and intergranular

1

Type 405 0.08 12.5 – – 0.2 (AI) corrosion in the presence of chloride

Type 430 0.08 14-18 – 0.02 ions, other materials have been exami-

Type 446 0.08 23-27 – 0.03 ned for caustic service.These include

Fe-Cr alloys, which are resistant to

High purity 0.002 12-30 0 to 2 0.008 SCC. However, these alloys are brittle.

Fe-Cr A popular alloy examined for the caustic

a Heat treated at 1150 C for 3 to 5 min. evaporator service was E-Brite-26-1,

o

using nickel or SS tanks. Non-metallics pickup of iron in caustic is acceptable. containing 26% Fe and 1% Mo, which

useful for caustic service within their Corrosion rate as a function of the exhibited performance characteristics

normal temperature limits include Nickel content in alloys in boiling comparable to that of nickel. However,

PVC, polypropylene, phenolics, PTFE, 40% NaOH solutions are presented in it suffered from serious intergranular

FEP, PVDF, natural rubber, neoprene, Figure-17 and Table-3 depicts the typical corrosion problems, which were attri-

halogenated polyesters, and chloro- composition of various stainless steels. buted to changes in the metallurgy and

sulphonated polyethylene (15, 16). chemistry of this material. E-Brite 26-1

Austenitic stainless steels show uni- is not used in new caustic evaporators

Stainless steel form corrosion and intergranular cor- (15, 16).

A comparison of corrosion rates in rosion in NaOH solutions. Figures-18

hot concentrated NaOH solutions asa and 19 illustrate the corrosion rate of Nickel

function of the nickel content in the materials inboiling 30% NaOH and 50% Nickel is the ideal material for hand-

alloys shows that nickel is extremely NaOH solutions, determined by weight ling caustic at all concentrations and

resistant to NaOH. Stainless steels are loss measurements and linear polariza- temperatures, including molten anhy-

acceptable for caustic service if the tion methods in hydrogen-saturated drous caustic up to 480°C. Nickel and

Chemical Weekly December 3, 2024 191

Contents Index to Advertisers Index to Products Advertised