Page 186 - CW E-Magazine (3-12-2024)

P. 186

Special Report

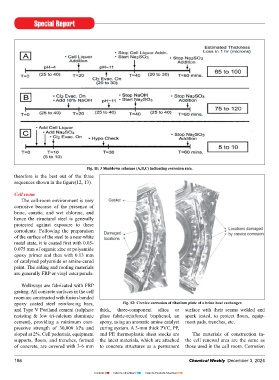

Fig. 11: 3 Shutdown schemes (A,B,C) indicating corrosion rate.

therefore is the best out of the three

sequences shown in the figure(12, 13).

Cell room

The cell-room environment is very

corrosive because of the presence of

brine, caustic, and wet chlorine, and

hence the structural steel is generally

protected against exposure to these

corrodents. Following the preparation

of the surface of the steel to a near-white

metal state, it is coated first with 0.05-

0.075 mm of organic zinc or polyamide

epoxy primer and then with 0.13 mm

of catalysed polyamide or amine-cured

paint. The siding and roofing materials

are generally FRP or vinyl ester panels.

Walkways are fabricated with FRP

grating. All concrete surfaces in the cell

room are constructed with fusion-bonded

epoxy coated steel reinforcing bars, Fig. 12: Crevice corrosion of titanium plate of a brine heat exchanger.

and Type V Portland cement (sulphate thick, three-component silica or surface with their seams welded and

resisting & low tri-calcium aluminate glass fabric-reinforced bisphenol, an spark tested, to protect floors, equip-

cement), providing a minimum com- epoxy, using an aromatic amine catalyst ment pads, trenches, etc.

pressive strength of 30,000 kPa and curing system. A 3-mm thick PVC, PP,

sloped at 2%. Cell pedestals, equipment and PE thermoplastic sheet stocks are The materials of construction in-

supports, floors, and trenches, formed the latest materials, which are attached the cell renewal area are the same as

of concrete, are covered with 3-6 mm to concrete structures as a permanent those used in the cell room. Corrosion

186 Chemical Weekly December 3, 2024

Contents Index to Advertisers Index to Products Advertised