Page 181 - CW E-Magazine (3-12-2024)

P. 181

Special Report

Material selection for preventing corrosion in chlor-

alkali sector

INTRODUCTION potential differences across the cell room Dr. S.K. ChaKravorty

hlorine and sodium hydroxide under load. Operational conditions of the Consultant (Plant Engineering)

(or caustic soda) are among the process (temperature, current density, Email: chakravorty4410@gmail.com

Ctop 10 chemicals produced in etc.) are chosen close to the stability

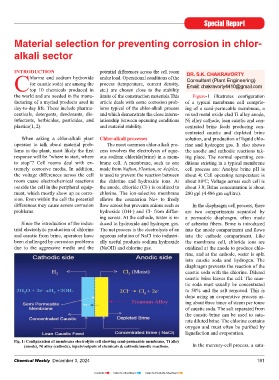

the world and are needed in the manu- limits of the construction materials.This Figure-1 illustrates configuration

facturing of a myriad products used in article deals with some corrosion prob- of a typical membrane cell compris-

day-to-day life. These include pharma- lems typical of the chlor-alkali process ing of a semi-permeable membrane, a

ceuticals, detergents, deodorants, dis- and which demonstrate the close interre- mixed metal oxide clad Ti alloy anode,

infectants, herbicides, pesticides, and lationship between operating conditions Ni alloy cathode, lean caustic and con-

plastics(1, 2). and material stability. centrated brine feeds producing con-

centrated caustic and depleted brine

When asking a chlor-alkali plant Chlor-alkali processes solution, and production of liquid chlo-

operator to talk about material prob- The most common chlor-alkali pro- rine and hydrogen gas. It also shows

lems in the plant, most likely the first cess involves the electrolysis of aque- the anodic and cathodic reactions tak-

response will be “where to start, where ous sodium chloride(brine) in a mem- ing place. The normal operating con-

to stop”? Cell rooms deal with ex- brane cell. A membrane, such as one ditions existing in a typical membrane

tremely corrosive media. In addition, made from Nafion, Flemion, or Aciplex, cell process are: Anolyte brine pH is

the voltage differences across the cell is used to prevent the reaction between about 4; Cell operating temperature is

room cause electrochemical reactions the chlorine and hydroxide ions. At about 88 C; Voltage across each cell is

o

outside the cell in the peripheral equip- the anode, chloride (Cl-) is oxidized to about 3.0; Brine concentration is about

ment, which mostly show up as corro- chlorine. The ion-selective membrane 280 gpl (4.486 gm eq/litre).

sion. Even within the cell the potential allows the counterion Na+ to freely

differences may cause severe corrosion flow across but prevents anions such as In the diaphragm cell process, there

problems. hydroxide (OH-) and Cl- from diffus- are two compartments separated by

ing across. At the cathode, water is re- a permeable diaphragm, often made

Since the introduction of the indus- duced to hydroxide and hydrogen gas. of asbestos fibers. Brine is introduced

trial electrolytic production of chlorine The net process is the electrolysis of an into the anode compartment and flows

and caustic from brine, operators have aqueous solution of NaCl into industri- into the cathode compartment. Like

been challenged by corrosion problems ally useful products sodium hydroxide the membrane cell, chloride ions are

due to the aggressive media and the (NaOH) and chlorine gas. oxidized at the anode to produce chlo-

rine, and at the cathode, water is split

into caustic soda and hydrogen. The

diaphragm prevents the reaction of the

caustic soda with the chlorine. Diluted

caustic brine leaves the cell. The caus-

tic soda must usually be concentrated

to 50% and the salt removed. This is

done using an evaporative process us-

ing about three tones of steam per tonne

of caustic soda. The salt separated from

the caustic brine can be used to satu-

rate diluted brine. The chlorine contains

oxygen and must often be purified by

liquefaction and evaporation.

Fig. 1: Configuration of membrane electrolytic cell showing semi-permeable membrane, Ti alloy

(anode), Ni alloy (cathode), inputs/outputs of chemicals & cathodic/anodic reactions. In the mercury-cell process, a satu-

Chemical Weekly December 3, 2024 181

Contents Index to Advertisers Index to Products Advertised