Page 192 - CW E-Magazine (27-2-2024)

P. 192

Special Report

Table 2: Corrosion condition related with half-cell potential measurements sibility of corrosion. Various condition

OCP values OCP values Corrosion condition survey assessments have been made

(Mv vs SCE) (Mv vs CSE) using this technique(11).

< - 426 < -500 Severe corrosion Concrete resistivity measurement

< - 276 < -350 High (90% risk of corrosion) The electrical resistivity of concrete

-126 to -275 - 350 to - 200 Intermediate corrosion risk is an important parameter concerning

>- 125 > -200 Low (10% risk of corrosion) determination of intensity of corrosion

initiation. In concrete with high elec-

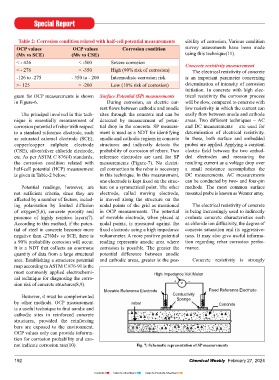

gram for OCP measurements is shown Surface Potential (SP) measurements trical resistivity the corrosion process

in Figure-6. During corrosion, an electric cur- will be slow, compared to concrete with

rent flows between cathodic and anodic low resistivity in which the current can

The principal involved in this tech- sites through the concrete and can be easily flow between anode and cathode

nique is essentially measurement of detected by measurement of poten- areas. Two different techniques – AC

corrosion potential of rebar with respect tial drop in the concrete. SP measure- and DC measurements – are used for

to a standard reference electrode, such ment is used as a NDT for identifying determination of electrical resistivity.

as saturated calomel electrode (SCE), anodic and cathodic regions in concrete In these, both surface and embedded

copper/copper sulphate electrode structures and indirectly detects the probes are applied. Applying a constant

(CSE), silver/silver chloride electrode, probability of corrosion of rebars. Two electric field between the two embed-

etc. As per ASTM C 876(4) standards, reference electrodes are used for SP ded electrodes and measuring the

the corrosion condition related with measurements (Figure-7). No electri- resulting current as a voltage drop over

half-cell potential (HCP) measurement cal connection to the rebar is necessary a small resistance accomplishes the

is given in Table-2 below: in this technique. In this measurement, DC measurements. AC measurements

one electrode is kept fixed on the struc- can be conducted by two- and four-pin

Potential readings, however, are ture on a symmetrical point. The other methods. The most common surface

not sufficient criteria, since they are electrode, called moving electrode, mounted probe is known as Wenner array.

affected by a number of factors, includ- is moved along the structure on the

ing polarisation by limited diffusion nodal points of the grid as mentioned The electrical resistivity of concrete

of oxygen(5,6), concrete porosity and in OCP measurements. The potential is being increasingly used to indirectly

presence of highly resistive layers(7). of movable electrode, when placed at evaluate concrete characteristics such

According to this method, if the poten- nodal points, is measured against the as chloride ion diffusivity, the degree of

tial of steel in concrete becomes more fixed electrode using a high impedance concrete saturation and its aggressive-

negative than -276Mv vs SCE, there is voltammeter. A more positive potential ness. It may also give useful informa-

a 90% probability corrosion will occur. reading represents anodic area where tion regarding rebar corrosion perfor-

It is a NDT that collects an enormous corrosion is possible. The greater the mance.

quantity of data from a large structural potential difference between anodic

area. Establishing a structures potential and cathodic areas, greater is the pos- Concrete resistivity is strongly

map according to ASTM C 876-91 is the

most commonly applied electrochemi- High Impedance Volt Meter

cal technique for diagnosing the corro- + –

sion risk of concrete structures(8,9). v

Movable Reference Electrode Fixed Reference Electrode

However, it must be complemented Conductivity

by other methods. OCP measurement rebar Sponge Concrete

is a useful technique to find anodic and

cathodic sites in reinforced concrete

structures, provided the reinforcing

bars are exposed to the environment.

OCP values only can provide informa-

tion for corrosion probability and can-

not indicate corrosion rate(10). Fig. 7: Schematic representation of SP measurements

192 Chemical Weekly February 27, 2024

Contents Index to Advertisers Index to Products Advertised