Page 191 - CW E-Magazine (27-2-2024)

P. 191

Special Report

it provides useful information about the corrosion is determined. Measurement GPR is more accurate and robust to

microstructure of the concrete material. of half-cell corrosion potential using a monitor the post-corrosion-initiation

The test procedure has since been stan- hand-held instrument is illustrated in signs and side-effects. It is not effec-

dardised by AASHTO TP 95. A stan- Figure-4. tive to monitor corrosion signs at early

dard set-up for carrying out electrical stages (Figure-5).

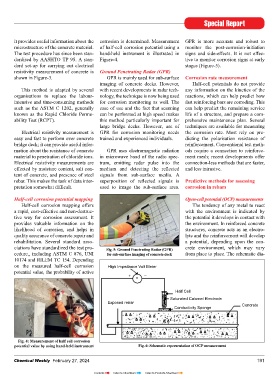

resistivity measurement of concrete is Ground Penetrating Radar (GPR)

shown in Figure-3. GPR is mainly used for sub-surface Corrosion rate measurement

imaging of concrete decks. However, Half-cell potentials do not provide

This method is adapted by several with recent developments in radar tech- any information on the kinetics of the

organisations to replace the labour- nology, the technique is now being used reactions, which can help predict how

intensive and time-consuming methods for corrosion monitoring as well. The fast reinforcing bars are corroding. This

such as the ASTM C 1202, generally ease of use and the fact that scanning can help predict the remaining service

known as the Rapid Chloride Perme- can be performed at high speed makes life of a structure, and prepare a com-

ability Test (RCPT). this method particularly important for prehensive maintenance plan. Several

large bridge decks. However, use of techniques are available for measuring

Electrical resistivity measurement is GPR for corrosion monitoring needs the corrosion rate. Most rely on pre-

easy and fast to perform over concrete trained and experienced individuals. dicting the polarisation resistance of

bridge deck; it can provide useful infor- reinforcement. Conventional test meth-

mation about the resistance of concrete GPR uses electromagnetic radiation ods require a connection to reinforce-

material to penetration of chloride ions. in microwave band of the radio spec- ment mesh; recent developments offer

Electrical resistivity measurements are trum, emitting radar pulse into the connection-less methods that are faster,

effected by moisture content, salt con- medium and detecting the reflected and less intrusive.

tent of concrete, and presence of steel signals from sub-surface media. A

rebar. This makes the task of data inter- superposition of reflected signals is Predictive methods for assessing

pretation somewhat difficult. used to image the sub-surface area. corrosion in rebars

Half-cell corrosion potential mapping Open-cell potential (OCP) measurements

Half-cell corrosion mapping offers The tendency of any metal to react

a rapid, cost-effective and non-destruc- with the environment is indicated by

tive way for corrosion assessment. It the potential it develops in contact with

provides valuable information on the the environment. In reinforced concrete

likelihood of corrosion, and helps in structures, concrete acts as an electro-

quality assurance of concrete repair and lyte and the reinforcement will develop

rehabilitation. Several standard asso- a potential, depending upon the con-

ciations have standardized the test pro- Fig. 5: Ground Penetrating Radar (GPR) crete environment, which may vary

cedure,, including ASTM C 876, UNI for sub-surface imaging of concrete deck from place to place. The schematic dia-

10174 and RILEM TC 154. Depending

on the measured half-cell corrosion High Impedance Volt Meter

potential value, the probability of active

+ v –

Half Cell

Saturated Calomel Electrode

Exposed rebar Concrete

Conductivity Sponge

Fig. 4: Measurement of half cell corrosion

potential value by using hand-held instrument Fig. 6: Schematic representation of OCP measurement

Chemical Weekly February 27, 2024 191

Contents Index to Advertisers Index to Products Advertised