Page 185 - CW E-Magazine (17-12-2024)

P. 185

Special Report Special Report

Continuous fl ow synthesis strategies for some solution, taken for further purifi cation;

and (iii) the fi nal yields were 87-88%.

important drugs, APIs and intermediates: A path In 2019, a similar protocol was

towards sustainability reported by Levesque and co-workers

to prepare 2-cyano-5-fl uoropyridine, a

critical intermediate for the synthesis

INTRODUCTION of Verubecestat. However, the deve-

he Indian Pharmaceutical In- CFS used in some reaction types DR. SANGHAPAL D. SAWANT lopment of this experimental drug for

dustry has gained a different In this articles, we are going to DR. AMOL A. KULKARNI Alzheimer’s disease was discontinued

Tkind of accelerated momentum focus on very specifi c reaction types CSIR-National Chemical Laboratory during Phase III clinical trials because

after the announcement of Production that are among the backbone transfor- Dr. Homi Bhabha Road, Pune-411008 the drug was unlikely to exhibit a posi- fl uoroadenine from an inexpensive Pro reactor equipped with a PtO cata-

2

Linked Incentive (PLI schemes – PLI-1 mations of the pharma industry. The sd.sawant@ncl.res.in & tive benefi t-to-risk ratio. (Snead, et al., 2,6-diaminopurine; (ii) Improved yield lyst cartridge. Complete conversion of

and PLI-2 – the fi rst one focusing on idea is to give a brief account of the aa.kulkarni@ncl.res.in Tetrahedron. 2019, 75, 4261–4265). and purity of pharmaceutical interme- alcohol 77 into a deiodinated product,

the possible import substitution of Key recent developments in specifi c types diate (2-fl uoroadenine); and (iii) More 78, was observed in less than 1 min of

Starting Materials (KSMs) and the of reactions to give confi dence to (Cantillo et al., J. Org. Chem. 2014, Advantages over batch process robust process. residence time (50°C, 20 bar). Product

second on strengthening the process- the organic chemists about CFS. The 79, 8486-8490). Reaction conditions are: (i) The reaction was demonstrated 78 was obtained in 73% yield in three

ing capabilities in niche areas where selected reactions include: are quite mild and integration of photo- under continuous fl ow conditions to Later, the authors adopted a “mix- steps (productivity: 7.6 g/h).

Indian pharma is already sound. Gain- Fluorination and fl uoroalkylation; chemistry helps to accelerate the reac- address process safety concerns related and-reside” approach, where the re-

ing any traction from these schemes Chlorination; tion in a much greener manner than the to build-up of unstable diazonium salts; action mixture from the T-mixer fi rst Pentafl uoro-1-ol is a desired side

is possible in long term only if the Grignard; conventional synthesis protocol. (ii) Upgraded selectivity over 66:1 passed through a stainless-steel coil chain of fulvestrant. (Rosso et al., Org.

new manufacturing facilities adhere Nitration & diazotization; and in batch process; (iii) Use of reusable reactor (0.03” i.d.) for effi cient heat Lett. 2019, 21, 5341-5345). Advantages

to sustainability aspects including Alkylation. Advantages over batch process ionic liquid; and (iv) 79% overall yield exchange and then underwent a sec- over batch process include: (i) Method

Green Chemistry principles. One of include: (i) Selectfl uor as the fl uorine when compared to 74% in batch mode. ond PFA reactor with a wider diameter enables dramatically elevated produc-

the important ways to achieve this is Continuous – fl ow fl uorination and source and xanthone as an inexpensive (0.063” i.d.) for complete conversion. tivity versus batch processes; (ii) In situ-

by adapting continuous fl ow synthesis fl uoroalkylation strategies for the and commercially available photo- In the same year, the Marzijarani, The photochemical step for the in- ations with light-sensitive substrates,

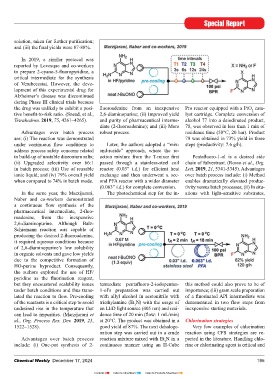

(CFS) and it indeed needs relooking synthesis of APIs organocatalyst; (ii) Reaction time less Naber and co-workers demonstrated

at the synthesis approach, including In 2017, the Sandford group reported than 30 min.; (iii) Selectivity more than a continuous fl ow synthesis of the

reinventing the chemistry right from a synthesis of Flucytosine using fl uo- 90%; and (iv) isolated yield of 80%. pharmaceutical intermediate, 2-fl uo-

the laboratory scale. Here we present to rine gas in continuous fl ow. Flucyto- roadenine, from the inexpensive

you a few laboratory scale successful sine is a WHO essential medicine used Celestolide is a common ingre- 2,6-diaminopurine. Although Balz-

case studies from the recent literature, to treat Cryptococcal meningitis (CM) dient utilised for fragrance compositions. Schiemann reaction was capable of

where CFS has been used for develop- fungal infection. The authors shortened Modifi cations were made to introduce producing the desired 2-fl uoroadenine,

ing early stage proof-of-concept for the previously four-step manufacturing DCM immediately after the photoreac- it required aqueous conditions because

specifi c pharma molecules. route into a single-step by using fl uo- tor for in-line dilution and the output of 2,6-diaminopurine’s low solubility

rine gas and formic acid to directly fl u- was collected through a silica gel fi lter in organic solvents and gave low yields

In recent past CFS has gained orinate cytosine. (Harsanyi et al., Org. for rapid quenching and it prevented due to the competitive formation of

much attention in the Indian pharma Process Res. Dev. 2017, 21, 273-276). decomposition, which is diffi cult to HO-purine byproduct. Consequently,

industry, but not to that extent as in achieve in batch mode. With a residence the authors explored the use of HF/

the global pharma industries. The Advantages over batch process: (i) time of only 9 minutes and a fl ow rate pyridine as the fl uorination reagent,

developments in the application of this Number of steps reduced down from of 3 mL/min, 100 mL of reaction mix- but they encountered scalability issues termediate pentafl uoro-2-iodopentan- this method could also prove to be of

technique have been remarkable and four to one; and (ii) Low initial capital ture was processed to give 2.3 grams of under batch conditions and thus trans- 1-ol’s preparation was carried out importance; (iii) gram scale preparation

several research groups have made expenditure for scalable laboratory to F-celestolide (87% yield), which cor- lated the reaction to fl ow. Pre-cooling with allyl alcohol in acetonitrile with of a fl uorinated API intermediate was

signifi cant impact by implementing pilot. responds to a production rate of about of the reactants is a critical step to avoid triethylamine (Et N) with the usage of demonstrated in two fl ow steps from

3

the strategies for synthesis of drugs/ 0.016 mol per hour (Cantillo, et al. J. undesired rise in the temperature that an LED light source (405 nm) and resi- inexpensive starting materials.

drug intermediates/active pharma- In 2014, Kappe and de Frutos deve- Org. Chem. 2014, 79, 8486–8490). can lead to impurities. (Marzijarani et dence time of 20 min (fl ow: 1 mL/min)

ceutical intermediates (APIs)/KSMs. loped a continuous fl ow protocol for al., Org. Process Res. Dev. 2019, 23, at 20°C. The product was obtained in a Chlorination strategies

It summarises some of the above light-induced fl uorination of benzylic Advantages over batch process 1522–1528). good yield of 87%. The next dehaloge- Very few examples of chlorination

reaction types with few examples compounds using Selectfl uor. They include: (i) Complete conversion and nation step was carried out in a crude reaction using CFS strategies are re-

of published methods on important utilized the developed strategy for the excellent selectivity; (ii) the fl uorinated Advantages over batch process reaction mixture mixed with Et N in a ported in the literature. Handling chlo-

3

molecules. synthesis of F-ibuprofen methyl ester. product was stable in the obtained crude include: (i) One-pot synthesis of 2- continuous manner using an H-Cube rine or chlorinating agent is critical and

184 Chemical Weekly December 17, 2024 Chemical Weekly December 17, 2024 185

Contents Index to Advertisers Index to Products Advertised