Page 191 - CW E-Magazine (26-9-2023)

P. 191

Special Report

modynamic efficiency, in the range

of 40-60%, significantly higher than

combustion-based systems. This higher

energy conversion efficiency leads

to improved overall performance and

reduced fuel consumption. The only

by-product from the reaction that

occurs within fuel cells is water. Additio-

nally, fuel cells provide versatility in

terms of fuel options, utilising various

fuels, including hydrogen, natural gas,

methanol, and ethanol. When utilising

fuels other than hydrogen, the quantity

of pollutants emitted is two orders of

magnitude lower than that produced

by conventional sources of electricity.

This brings up the possibility of using

existing infrastructure to provide fuel

cells with their fuels. In terms of power

output, fuel cells are flexible and can

be scaled for power production in the

Fig. 5: Microbial Fuel cell Diagram region from 50-W to 100-MW.

dependent on the ion mobility and the can be scaled up for commercial use

electrolyte conductivity. This is why also determine whether a technology’s Disadvantages of fuel cells include

certain fuel cells are better than others, performance is fit for use as an energy high costs compared to conventional

as some may use ions which have source. power generation technologies, which

a higher ion mobility and therefore is mainly attributed to factors such as

offer less resistance. A fuel cell’s perfor- summary catalyst materials, system components,

mance can be evaluated based on its Generally, fuel cells offer several and manufacturing processes. Utilising

efficiency and total output. Other fac- advantages over traditional power gene- expensive catalysts such as platinum

tors such as temperature, or whether it ration methods. They exhibit high ther- means that using fuel cells for large

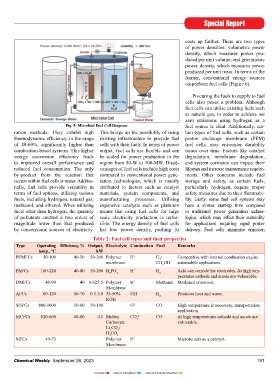

table 2: Fuel cell types and their properties

type Operating Efficiency, % Output, Electrolyte conduction Fuel remarks

temp., °c kW

PEMFCs 50-100 40-50 50-200 Polymer H + H / Competitive with internal combustion engine –

2

membrane CH OH automobile applications.

3

PAFCs 160-220 40-80 50-200 H PO H + H Acid can corrode the electrodes. At high tem-

3 4 2

peratures cathode and anode are vulnerable.

DMFCs 40-90 40 0.025-5 Polymer H + Methanol Methanol crossover.

Membrane

AFCs 60-120 60-70 0.3-5.0 35-50% OH – H 2 Produces heat and water.

KOH

SOFCs 800-1000 50-60 50-100 O 2– CO High temperature is necessary, transportation

application.

MCFCs 620-660 60-80 0.1 Molten CO 3 2– CO At high temperatures cathode and anode are

Carbonate vulnerable.

Li CO /

2

3

H CO

2 3

MFCs 49-53 Polymer H + Microbe acts as a catalyst.

Membrane

Chemical Weekly September 26, 2023 191

Contents Index to Advertisers Index to Products Advertised