Page 189 - CW E-Magazine (26-9-2023)

P. 189

Special Report

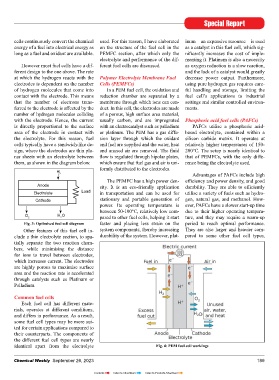

cells continuously convert the chemical types are nearly identical apart from the between 50-100°C, relatively low com-

energy of a fuel into electrical energy as electrolyte used. For this reason, I have pared to other fuel cells, helping it start

long as a fuel and oxidant are available. elaborated on the structure of the fuel faster and placing less strain on the

cell in the PEMFC section, after which system components, thereby increasing

However most fuel cells have a dif- only the electrolyte and performance of durability of the system.

ferent design to the one above. The rate the different fuel cells are discussed.

at which the hydrogen reacts with the However, platinum – an expensive

electrodes is dependent on the number Polymer Electrolyte Membrane Fuel resource – is used as a catalyst in this

of hydrogen molecules that come into Cells (PEMFCs) fuel cell, which significantly increases

contact with the electrode. This means In a PEM fuel cell, the oxidation and the cost of implementing it. Platinum is

that the number of electrons trans- reduction chamber are separated by a also a necessity as oxygen reduction is

ferred to the electrode is affected by the membrane through which ions can con- a slow reaction, and the lack of a cata-

number of hydrogen molecules colliding duct. In this cell, the electrodes are made lyst would greatly decrease power out-

with the electrode. Hence, the current of a porous, high surface area material, put. Furthermore, using pure hydrogen

is directly proportional to the surface usually carbon, and are impregnated gas requires careful handling and stor-

area of the electrode in contact with with an electrocatalyst such as palladium age, limiting the fuel cell’s applications

the electrolyte. For this reason, fuel or platinum. The PEM has a gas diffu- to industrial settings and similar con-

cells typically have a sandwich-like de- sion layer through which the oxidant trolled environments.

sign, where the electrodes are thin pla- and fuel are supplied and the water, heat

nar sheets with an electrolyte between and unused air are removed. The fluid Phosphoric acid fuel cells (PAFCs)

them, as shown in the diagram below. flow is regulated through bipolar plates, PAFCs utilise a phosphoric acid-

which ensure that fuel gas and air is uni- based electrolyte, contained within a

H

2 formly distributed to the electrodes. silicon carbide matrix. It operates at

relatively higher temperatures of 150-

Anode The PEMFC has a high power den- 200°C. The setup is nearly identical to

Electrolyte Load sity. It is an eco-friendly application that of PEMFCs, with the only diffe-

Cathode in transportation and can be used for rence being the electrolyte used.

stationary and portable generation of

power. Its operating temperature is Advantages of PAFCs include high

O 2 H O

2

Fig. 3: Optimised fuel cell diagram

Other features of this fuel cell in-

clude a thin electrolyte section, to spa-

tially separate the two reaction cham-

bers, while minimising the distance

for ions to travel between electrodes,

which increases current. The electrodes

are highly porous to maximise surface

area and the reaction rate is accelerated

through catalysts such as Platinum or

Palladium.

common fuel cells

Each fuel cell has different mate-

rials, operates at different conditions,

and differs in performance.

As a result, some fuel cell types may

be more suited for certain applications

compared to their counterparts. The

components of the different fuel cell Fig. 4: PEM fuel cell workings

Chemical Weekly September 26, 2023 189

Contents Index to Advertisers Index to Products Advertised