Page 197 - CW E-Magazine (8-10-2024)

P. 197

Special Report Special Report

CH OH-CH OH + O 2CHOCHO vity against oomycetes, including

Glyoxylic acid – A techno-commercial profi le ~40°C and is carried out industrially = 2H O 2 2 2 downy mildew on grapes (Plasmo-

as a continuous process. The maxi-

mum yield is ~70% and selectivity is 2 para viticola) and late blight on

ogether with acetic acid, gly- in 2018, down from a total of 4.1-mt B.G. SAMPAT a function of the relative concentra- Other processes potatoes and tomatoes (Phytophtho-

colic acid, and oxalic acid, in 1990. Total greenhouse gas (GHG) Consultant tions of reagents. After removal of Several other processes for gly- ra infestans). They are active against

Tglyoxylic acid (GA) is one emissions from CGGA production Email: bgsampat@gmail.com the excess acetaldehyde, the glyoxal oxal have been developed, but Oomycetes in soil such as Phyto-

of the C2 carboxylic acids. It is a went down by an average of 2.4%/y formed, which is contaminated with not utilised commercially. These phthora in tobacco and citrus.

strong organic acid and a highly re- between 1990 and 2018. Nearly half The cathodic oxidation-reduction acetic acid, formic acid and GA, is include:

active chemical intermediate having of the original emission values in of oxalic acid gives a very good purified by passage through an ion Ethylene oxidation by aqueous This class of compounds can be

two functional groups: the aldehyde 1990 have been reduced. Long-term chemical yield (~85%), but this tech- exchange resin. The solution is then nitric acid in the presence of synthesized via a simple synthetic

group and the carboxylic acid group. data shows a signifi cant reduction of nique encounters problems with passi- concentrated to a glyoxal content of palladium, by atmospheric oxygen, approach where in the second step

Because of its bi-functionality GA is GHG emissions between 1990 and vation of the lead electrodes. about 40%. or by selenium oxide deposited the glycolic acid ester is needed.

a versatile reagent in chemicals syn- 2003. Total GHG emissions from on silica;

theses, with diversifi ed utility in per- CGGA production went down by an Another method is oxidative 2CH CHO + 2HNO 3 2CHO- Oxidation of acetylene or ben- Pharmaceuticals

3

fumery, fl avour, pharmaceutical, and average of 6.0%/y between 1990 and cleavage of maleic acid or its esters CHO + 3H O + N O zene with ozone; GA is either a raw material or

2

2

agrochemical industries. 2003. Since 2004, GHG emissions by ozone. This process has been Oxidation of ethylene oxide; and used as an intermediate in the syn-

have been relatively fl at. In relative adapted to the preparation of hemi- The stoichiometric relationship Reduction of oxalic acid and its thesis of various pharmaceutical

GA is sold commercially as a terms, GHG emissions from produc- acetal esters. indicates that a complete reaction derivatives. products like DL-p-hydroxyphenyl-

50% aqueous solution and currently will produce 380-kg of N O per glycine, DL-p-hydroxyphenylhydan-

2

manufactured either by nitric acid Table 1: Raw material consumption In May 2021, the EU’s Horizon tonne of glyoxal. Applications of GA(4) toin, orotic aid, sulindac, mandelic

oxidation of glyoxal or ozonolysis of for GA from glyoxal 2020 programme awarded Nether- acid, p-hydroxyphenylacetic acid,

dimethyl maleate(1). Raw material Quantity lands based company, Avantium, a From ethylene glycol Agrochemicals diphenylacetic acid, Lamivudine and

Glyoxal (40%) 1.223 $2.2-mn grant to develop an electro- The gas-phase oxidation of ethy- GA is used as a key raw material p-aminophenylacetic acid.

Manufacture of GA catalytic process that transforms CO lene glycol by oxygen in the presence for the synthesis of e.g. Ethylene

2

GA is produced industrially by Aqueous HCl (30%) 0.725 into industrial chemicals, including of dehydrogenation catalysts (metallic bis(hydroxyphenyl)glycine, glypho- p-hydroxyphenylacetic acid is an

the oxidation of glyoxal in aqueous Nitric acid (68%) 0.016 GA, formic acid, glycolic acid, and copper or silver) represents the basis sate, 2-hydroxyquinoxaline and com- important intermediate for the semi-

solution with 65% nitric acid in mole Sodium nitrate 0.0010 fuels(3). of the Laporte process and has been plexing agents like EDDHA. synthetic penicillin, amoxycillin.

ratios of 1:1 to 1:1.5 between 40°C Per kg of GA used in several industrial processes.

and 80°C. The main byproduct of this Manufacture of glyoxal

process is oxalic acid, which is sepa- ing CGGA accounted for 3.5% of Among the numerous processes The reaction occurs between

rated by low-temperature crystallisa- total GHG emissions in the EU27 for producing glyoxal, only those 400°C and 600°C and the yield is

tion. The solution is then purifi ed by chemical industry in 2018 (2.1-mt vs using acetaldehyde and ethylene glycol 70-80%. The main impurity formed

passage through an anion exchange 60.6-mt)(2). as starting materials have been is formaldehyde, whose subsequent

resin or by electrodialysis, which developed commercially and both separation is difficult.

removes the residual nitric acid. GA may also be synthesised by are continuous processes.

the catalytic oxidation of ethylene or BASF uses this process for the

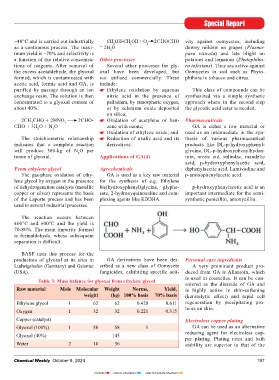

4CHOCHO + 2HNO 4CHOCOOH acetaldehyde, but the selectivity is From acetaldehyde production of glyoxal at its sites in GA derivatives have been des- Personal care ingredients

+ N O + H O 3 low and these routes have not been Liquid phase oxidation of acetal- Ludwigshafen (Germany) and Geismar cribed as a new class of Oomycete A very prominent product pro-

2 2

used industrially. dehyde with nitric acid takes place at (USA). fungicides, exhibiting specific acti- duced from GA is Allantoin, which

The stoichiometric relationship is used in cosmetics. It can be con-

indicates that the complete reaction Table 2: Mass balance for glyoxal from acetaldehyde Table 3: Mass balance for glyoxal from ethylene glycol sidered as the diureide of GA and

will produce 149-kg of nitrous oxide Raw material Mole Molecular Weight Norms, Yield, Raw material Mole Molecular Weight Norms, Yield, is highly active in skin-softening

(N O) – a greenhouse gas – per tonne weight (kg) 100% basis 70% basis weight (kg) 100% basis 70% basis (keratolytic effect) and rapid cell

2

of GA. Acetaldehyde 2 44 88 0.3793 0.266 Ethylene glycol 1 62 62 0.428 0.611 regeneration by precipitating pro-

According to the European En- Nitric acid (65%) 2 63 126 0.8355 0.585 Oxygen 1 32 32 0.221 0.315 teins on skin.

vironmental Agency (EEA), the EU Glyoxal (100%) 2 59 116 1 Copper (catalyst) Electroless copper plating

production of caprolactam, glyoxal Glyoxal (40%) 232 1 Glyoxal (100%) 1 58 58 1 GA can be used as an alternative

and GA (CGGA) by the EU27 chemi- reducing agent for electroless cop-

cal industry emitted a total of 2.1-mt Water 3 18 54 Glyoxal (40%) 145 per plating. Plating rates and bath

of carbon dioxide equivalent (CO e) Nitrous oxide (N O) 1 44 44 Water 2 18 36 stability are superior to that of the

2 2

196 Chemical Weekly October 8, 2024 Chemical Weekly October 8, 2024 197

Contents Index to Advertisers Index to Products Advertised