Page 178 - CW E-Magazine (16-7-2024)

P. 178

Special Report

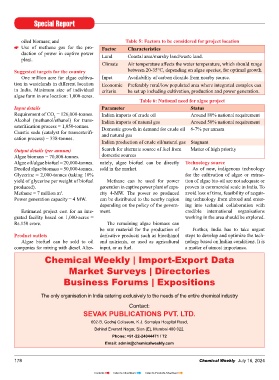

oiled biomass; and Table 5: Factors to be considered for project location

Use of methane gas for the pro- Factor Characteristics

duction of power in captive power Land Coastal area/marshy land/waste land.

plant.

Climate Air temperature affects the water temperature, which should range

Suggested targets for the country between 20-35°C, depending on algae species, for optimal growth.

One million acre for algae cultiva- Input Availability of carbon dioxide from nearby source.

tion in wastelands in different location Economic Preferably rural/low populated area where integrated complex can

in India. Minimum size of individual criteria be set up including cultivation, production and power generation.

algae farm in one location: 1,000-acres.

Table 6: National need for algae project

Input details Parameter Status

Requirement of CO = 126,000-tonnes. Indian imports of crude oil Around 80% national requirement

2

Alcohol (methanol/ethanol) for trans- Indian imports of natural gas Around 50% national requirement

esterifi cation process = 1,050-tonnes. Domestic growth in demand for crude oil 6-7% per annum

Caustic soda (catalyst for transesterifi - and natural gas

cation process) = 338-tonnes.

Indian production of crude oil/natural gas Stagnant

Output details (per annum) Search for alternate source of fuel from Matter of high priority

Algae biomass = 70,000-tonnes. domestic sources

Algae oil/algae biofuel = 20,000-tonnes. nately, algae biofuel can be directly Technology source

Deoiled algae biomass = 50,000-tonnes. sold in the market. As of now, indigenous technology

Glycerine = 2,000-tonnes (taking 10% for the cultivation of algae or extrac-

yield of glycerine per weight of biofuel Methane can be used for power tion of algae bio-oil are not adequate or

produced). generation in captive power plant of capa- proven in commercial scale in India. To

Methane = 7 million m . city 4-MW. The power so produced avoid loss of time, feasibility of acquir-

3

Power generation capacity = 4 MW. can be distributed to the nearby region ing technology from abroad and enter-

depending on the policy of the govern- ing into technical collaboration with

Estimated project cost for an inte- ment. credible international organisations

grated facility based on 1,000-acres = working in the area should be explored.

Rs.150 crore. The remaining algae biomass can

be raw material for the production of Further, India has to take urgent

Product outlets derivative products such as bioethanol steps to develop and optimize the tech-

Algae biofuel can be sold to oil and nutrients, or used as agricultural nology based on Indian conditions. It is

companies for mixing with diesel. Alter- input, or as fuel. a matter of utmost importance.

Chemical Weekly | Import-Export Data

Market Surveys | Directories

Business Forums | Expositions

The only organisation in India catering exclusively to the needs of the entire chemical industry

Contact:

SEVAK PUBLICATIONS PVT. LTD.

602-B, Godrej Coliseum, K.J. Somaiya Hospital Road,

Behind Everard Nagar, Sion (E), Mumbai 400 022.

Phone: +91-22-24044471 / 72

Email: admin@chemicalweekly.com

178 Chemical Weekly July 16, 2024

Contents Index to Advertisers Index to Products Advertised