Page 169 - CW E-Magazine (14-1-2025)

P. 169

Special Report

A rapid wrap-up of what’s new in Operations,

Processes and Products

General

To overcome this problem water gas

shift reaction is avoided and conversion

of coal gasification to make NG and

CH OH in series with high economic

3

benefit and risk resistance is developed.

This paper studies a life cycle assess-

ment of the title process. The proposed

series process has 35.9% less carbon

emissions than the single production

process. This proposal has many merits.

(ACS Sustainable Chem. Eng., 2024,

DOI: 10.1021/acssuschemeng.4c04851).

Sustainable and scalable syn-

thesis of acetal-containing poly-

ols as a platform for circular

polyurethanes (PU)

Recycling PVC with SCCO Life cycle assessment of the

2 coal-to-synthetic natural gas P. Schara et al have developed closed-loop

F.A. Versteeg et al have dealt with both (NG) methanol co-production recyclable PU materials by integrating

soft and rigid PVC whose recycling process in series cleavable acetal groups. Different alde-

does face problems. These authors have hydes, HCHO, CH CHO, CH CH CHO,

3

2

3

worked with supercritical (SC) CO to [There has been considerable emphasis were reacted with 1,6-hexanediol (H16)

2

remove plasticisers from PVC to allow on converting coal at coal mine site to and these were employed alongside

recycling. Experiments were done at 100 NG and CH OH so that these can be 4,4-methylene diisocyanates (MDI)

3

to 500 bar pressure and temperatures conveniently transported.] for preparing PU materials which had

from 75°C to 150°C. This strategy mechanical properties comparable to or sur-

allows removal of the well-known plasti- J. Liu et al have referred to a lot of passing those of conventional PUs. These

ciser bis(2-ethylhexyl)phthalate (DOP) pollutant discharge in the title process. can be recycled under acidic conditions.

with efficiency more than 98%. Model-

ling has been done; various tests were

performed on the PVC so recovered.

(ACS Sustainable Chem. Eng., 2024,

DOI: 10.1021/acssuschemeng.4c03743).

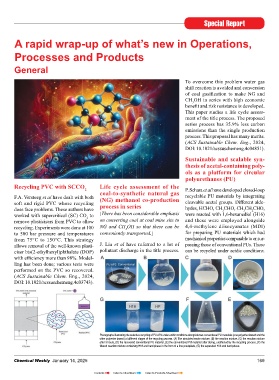

Photographs illustrating the selective recycling of PU AP2 under acidic conditions alongside two conventional PU materials (one polyether based and the

other polyester based) at different stages of the recycling process. (A) The simulated waste mixture, (B) the reaction mixture, (C) the reaction mixture

after 5 hours, (D) the recovered conventional PU material, (E) the conventional PU material after drying, unaffected by the recycling process, (F) the

filtered reaction mixture containing H16 and hard phase in the form of a fine precipitate, (G) the separated H16 and hard phase.

Chemical Weekly January 14, 2025 169

Contents Index to Advertisers Index to Products Advertised