Page 190 - CW E-Magazine (10-9-2024)

P. 190

Special Report

The influence of alloy composition

160

on SCC

Resistance to chloride SCC depends

ISO 15156 Limits for

140 AISI Types 316/316L on the type of SS being used. The aus-

CORROSIONPEDIA tenitic grades of SS are more prone

to SCC, and their resistance to SCC

120 depends on their nickel content.

Austenitic grades with nickel con-

100

ISO 15156 Technical tents in the range of 8-10 wt% (e.g.,

Temperature ( o C) 80 prone to such attack due to SCC. Aus-

Circular 2007 Revised

304/304L and 316/316L) are more

Limits

tenitic grades that have high nickel and

molybdenum contents such as alloy 20,

60

904L and the 6% molybdenum super

austenitic grades are superior with

40 respect to SCC.

The ferritic grades of SS, such as

20 type 430 and 444, are also very resis-

ISO 15156: 2003 Limits tant to chloride SCC.(9, 10).

0

0.001 0.01 0.1 1 10 100 Conclusion

SCC is often the predominant failure

H S Partial Pressure (Bar) in buried high-pressure oil and gas

2

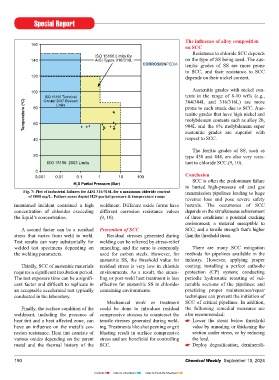

Fig. 7: Plot of industrial failures for AISI 316/316L for a maximum chloride content transmission pipelines leading to huge

of 1000 mg/L. Failure zones depict H2S partial pressure & temperature range

revenue loss and pose severe safety

mentioned incident contained a high weldment. Different oxide forms have hazards. The occurrence of SCC

concentration of chlorides exceeding different corrosion resistance values depends on the simultaneous achievement

the liquid’s concentration. (9, 10). of three conditions: a potential cracking

environment; a material susceptible to

A second factor can be a residual Prevention of SCC SCC; and a tensile strength that’s higher

stress that varies from weld to weld. Residual stresses generated during than the threshold stress.

Test results can vary substantially for welding can be relieved by stress-relief

welded test specimens depending on annealing, and the same is commonly There are many SCC mitigation

the welding parameters. used for carbon steels. However, for methods for pipelines available in the

austenitic SS, the threshold value for industry. However, applying proper

Thirdly, SCC of austenitic materials residual stress is very low in chloride coating; installing a perfect cathodic

requires a significant incubation period. environments. As a result, the annea- protection (CP) system; conducting

The test exposure time can be a signifi- ling or post-weld heat treatment is less periodic hydrostatic retesting of vul-

cant factor and difficult to replicate in effective for austenitic SS in chloride- nerable sections of the pipelines; and

an acceptable accelerated test typically containing environments. practicing proper maintenance/repair

conducted in the laboratory. techniques can prevent the initiation of

Mechanical work or treatment SCC of critical pipelines. In addition,

Finally, the surface condition of the could be done to introduce residual the following remedial measures are

weldment, including the presence of compressive stresses to counteract the also recommended:

heat tint and a heat affected zone, can tensile stresses generated during weld- Lower the stress below threshold

have an influence on the metal’s cor- ing. Treatments like shot peening or grit value by annealing or thickening the

rosion resistance. Heat tint consists of blasting result in surface compressive section under stress, or by reducing

various oxides depending on the parent stress and are beneficial for controlling the load.

metal and the thermal history of the SCC. Deploy degasification, deminerali-

190 Chemical Weekly September 10, 2024

Contents Index to Advertisers Index to Products Advertised