Page 189 - CW E-Magazine (10-9-2024)

P. 189

Special Report

of H2S above which precautions

Export

To Flare against environmental cracking are

considered necessary. In its first publi-

CORROSIONPEDIA cation in 2003, the limit of AISI 316L

SS is 60°C maximum when chlorides

exceed 50 ppm.

After conducting laboratory testing,

Discharge researchers argued that the limitation

for austenitic SS can be expanded to a

more severe environment than the origi-

nal ISO 15156 restrictions. In 2007, the

restrictions for AISI 316 materials were

updated and officially endorsed in the

2009 version of the standard.

The failures reported in the indus-

try occurred in an environment consid-

To Drains

ered susceptible under the current ISO

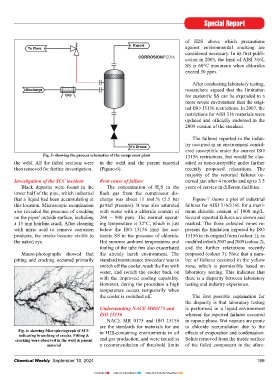

Fig. 5: showing the process schematics of the compressor plant 15156 restrictions, but would be clas-

the weld. All the failed sections were in the weld and the parent material sified as non-susceptible under further

then removed for further investigation. (Figure-6). recently proposed relaxations. The

majority of the reported failures oc-

Investigation of the SCC incident Root cause of failure curred just after 4 months and up to 3.5

Black deposits were found in the The concentration of H S in the years of service in different facilities.

2

lower half of the pipe, which indicated flash gas from the compressor dis-

that a liquid had been accumulating at charge was about 11 mol.% (5.5 bar Figure-7 shows a plot of industrial

this location. Microscopic examination partial pressure). It was also saturated failures for AISI 316/316L for a maxi-

also revealed the presence of cracking with water with a chloride content of mum chloride content of 1000 mg/L.

on the pipes’ outside surface, including 260 – 900 ppm. The normal operat- Several reported failures are shown and

a 13 mm hairline crack. After cleaning ing temperature is 52°C, which is just marked. The three coloured zones re-

with nitric acid to remove corrosion below the ISO 15156 limit for aus- present the limitation imposed by ISO

products, the cracks became visible to tenitic SS in the presence of chloride. 15156 in its original form (colour 1), as

the naked eye. Hot summer ambient temperatures and modified in both 2007 and 2009 (colour 2),

fouling of the tube fins also exacerbated and the further relaxations recently

Macro-photographs showed that the already harsh environment. The proposed (colour 3). Note that a num-

pitting and cracking occurred primarily standard maintenance procedure was to ber of failures occurred in the yellow

switch off the cooler, wash the fins with zone, which is permissible based on

water, and switch the cooler back on laboratory testing. This indicates that

with the improved cooling capability. there is a disparity between laboratory

However, during the procedure a high testing and industry experience.

temperature occurs temporarily when

the cooler is switched off. The first possible explanation for

the disparity is that laboratory testing

Understanding NACE MR0175 and is performed in a liquid environment

ISO 15156 whereas the reported failures occurred

NACE MR 0175 and ISO 15156 in vapour phase. Wet vapours are prone

are the standards for materials for use to chloride accumulation due to the

Fig. 6: showing Microphotograph of SCC in H2S-containing environments in oil effects of evaporation and condensation.

indicating branching of cracks. Pitting &

cracking were observed in the weld & parent and gas production, and were issued as Solids removed from the inside surface

material a recommendation of threshold limits of the failed component in the afore-

Chemical Weekly September 10, 2024 189

Contents Index to Advertisers Index to Products Advertised