Page 177 - CW E-Magazine (28-1-2025)

P. 177

Special Report Special Report

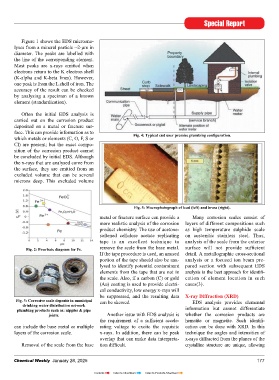

Figure 1 shows the EDS microana-

Techniques for analysing corrosion products with special lyses from a mineral particle ~2-μm in

emphasis on aqueous corrosion products & scale diameter. The peaks are labelled with

the line of the corresponding element.

Most peaks are x-rays emitted when

INTRODUCTION ple is only as good as what is being ana- DR. S.K. CHAKRAVORTY electrons return to the K electron shell

orrosion failure analysis is a lysed because many oxide and sulphide Consultant (Plant Engineering) (K-alpha and K-beta lines). However,

broad concept that spans diffe- corrosion products are susceptible to Email: chakravorty4410@gmail.com one peak is from the L shell of iron. The

Crent fi elds such as electronics, degradation upon atmospheric expo- accuracy of the result can be checked

mechanics, metallurgy, corrosion, etc. sure. Energy Dispersive X-ray Spectro- by analysing a specimen of a known

For a corrosion engineer, failure ana- scopy (EDS) element (standardization).

lysis is the study of a specifi c case of To carry out analysis, one has to EDS, associated with SEM, is the

component or equipment failure, due obtain representative samples of scales, most common technique for chemi- Often the initial EDS analysis is

to corrosion or mechanical aspects of deposits, corrosion products, etc. in cal identification of corrosion pro- carried out on the corrosion product

corrosion, conducted to determine the loose/adherent contact with the inside ducts. In EDS, an electron beam or deposited on a metal or fracture sur-

root causes for failure and how they surface of the equipment on the process x-ray is focused on a sample to stimu- face. This can provide information as to Fig. 4: Typical end user premise plumbing confi guration.

may be prevented in the future. side and on the outside surface if exter- late the emission of characteristic which metals or elements (C, O, F, S or

nal corrosion is suspected. In addition, x-rays. The energy and number of Cl) are present; but the exact compo-

There are several important reasons the samples need to be well-preserved. x-rays emitted from the sample are sition of the corrosion product cannot

to conduct a corrosion failure analysis: They should be properly identifi ed, measured by an energy-dispersive be concluded by initial EDS. Although

Determine the mechanism of corro- photographed, degreased, cleaned with spectrometer. The energies are charac- the x-rays that are analysed come from

sion in an industrial process; detergents (not acidic ones), dried and teristic of the atomic structure of the the surface, they are emitted from an

Suggest feasible guidelines and preserved in dry packets. emitting element and allow the ele- excluded volume that can be several

remedies to avoid the repetition of mental composition of the sample to microns deep. This excluded volume

similar corrosion failure; and Techniques such as scanning elec- be measured.

Investigate the damage to metallic tron microscopy (SEM), energy disper-

components after a chemical acci- sive x-ray spectroscopy (EDS), x-ray EDS can detect elements from car-

dent, fi re, leak or environmental diffraction (XRD), Fourier Transform bon (C) through uranium (U) with a Fig. 5: Macrophotograph of lead (left) and brass (right).

pollution. Infra-red (FTIR) spectroscopy, Raman detectability limit of about 0.1 weight

imaging, X-ray Fluorescence (XRF), percent. Unless standards are used, the metal or fracture surface can provide a Many corrosion scales consist of

Failure analysis process is usually etc. are employed to provide vital infor- analysis produces semi-quantitative more realistic analysis of the corrosion layers of different compositions such

performed in three stages: mation about corrosion products. analysis. product chemistry. The use of acetone- as high temperature sulphide scale

Obtaining and gathering information softened cellulose acetate replicating on austenitic stainless steel. Thus,

related to an equipment’s history; tape is an excellent technique to analysis of the scale from the exterior

Conducting a detailed examination Fig. 2: Pourbaix diagram for Fe. remove the scale from the base metal. surface will not provide suffi cient

of the failed part; and If the tape procedure is used, an unused detail. A metallographic cross-sectional

Addressing the reasons that caused portion of the tape should also be ana- analysis or a focused ion beam pre-

the failure. lysed to identify potential contaminant pared section with subsequent EDS

elements from the tape that are not in analysis is the best approach for identifi -

All corrosion reactions produce the scale. Also, if a carbon (C) or gold cation of element location in such

corrosion products, which include in- (Au) coating is used to provide electri- cases(3).

soluble hydroxides, carbonates, oxides, cal conductivity, low energy x-rays will

sulphides, and silicates. Analysing be suppressed, and the resulting data X-ray Diffraction (XRD)

these corrosion products is important Fig. 3: Corrosive scale deposits in municipal can be skewed. EDS analysis provides elemental

drinking water distribution network

for analysing the mechanism of corro- plumbing products such as: nipples & pipe information but cannot differentiate

sion(1, 2). It is a critical component of joints. Another issue with EDS analysis is whether the corrosion products are

failure analysis to conclude the root the requirement of a suffi cient accele- hematite or magnetite. Such identifi -

cause and determine the corrective can include the base metal or multiple rating voltage to excite the requisite cation can be done with XRD. In this

actions. layers of the corrosion scale. x-rays. In addition, there can be peak technique the angles and intensities of

Fig. 1: Elemental energy dispersive X-ray microanalyses from a mineral particle ~2 μm overlap that can make data interpreta- x-rays diffracted from the planes of the

However, the analysis of any sam- diameter. (The peaks are labelled with the line of the corresponding element). Removal of the scale from the base tion diffi cult. crystalline structure are unique, allowing

176 Chemical Weekly January 28, 2025 Chemical Weekly January 28, 2025 177

Contents Index to Advertisers Index to Products Advertised