Page 182 - CW E-Magazine (10-9-2024)

P. 182

Special Report Special Report

Global LNG markets heading towards supply glut; Stress corrosion cracking in buried pipelines with a

likely to benefi t India’s gas offtake: ICRA case example

fter two volatile years in terms 120 key challenge, given the falling share of

of natural gas supplies and pric- 100 the APM gas in the overall gas mix. INTRODUCTION stress and a corrosive medium. Metal or DR. S.K. CHAKRAVORTY

Aing in CY2022 and CY2023, 80 tress corrosion cracking (SCC) alloy is virtually unattacked over most Consultant (Plant Engineering)

the global liquifi ed natural gas (LNG) 60 The fertiliser segment will remain is often the predominant failure of its surface, while fi ne cracks progress Email: chakravorty4410@gmail.com

markets are now heading towards signi- 40 the largest off-taker of natural gas, albeit Sin high-pressure gas transmis- through it (Figure-1). After processing

fi cant supply glut with large capa- 20 the demand from hereon is not expect- sion pipelines. Long-term operation only a few batches, many cracks ap-

city additions planned from CY2024 to 0 ed to grow, given there are no further of pipelines could lead to degradation peared on the outside surface of a high-

Q1FY2025

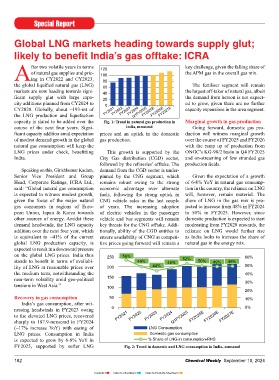

CY2028. Globally, about ~193-mt of FY2021 FY2022 FY2023 FY2024 FY2025E FY2026E FY2027E capacity expansions in the urea segment. of mechanical properties of the steel, pressure autoclave forged from 18-8 SS

the LNG production and liquefaction including a signifi cant reduction of with 2-in. wall. The surface was cooled Tensile Susceptible

capacity is slated to be added over the Fig. 1: Trend in natural gas production in Marginal growth in gas production brittle fracture resistance and resistance by water and the cooling-water-jacket Stress material

course of the next four years. Signi- india, mmscmd Going forward, domestic gas pro- to SCC. The impact toughness of oil system was drained after each opera- SCC

fi cant capacity addition amid expectation prices and an uptick in the domestic duction will witness marginal growth and gas pipeline steels, and the SCC tion. The droplets of water clinging

of modest demand growth in the global gas production. over the course of FY2025 and FY2026 resistance of pipeline steels, important to the autoclave surface dried and the

natural gas consumption will keep the with the ramp up of production from for structural integrity, are often not chloride present in water concentrated

LNG prices under check, benefi tting This growth is supported by the ONGC’s KG-98/2 basin in Q4 FY2025 regulated and given due consideration. causing SCC. Corrosive

India. City Gas distribution (CGD) sector, and on-streaming of few stranded gas environment

followed by the refi neries’ offtake. The production fi elds. SCC begins when small cracks Not all metal-environment combi-

Speaking on this, Girishkumar Kadam, demand from the CGD sector is under- develop on the external surface of nations are susceptible to cracking.

Senior Vice President and Group pinned by the CNG segment, which Given the expectation of a growth buried pipelines. In severe cases, it can Stainless steels crack in chloride Conditions necessary for SCC occur

Head, Corporate Ratings, ICRA Ltd., remains robust owing to the strong of 6-8% YoY in natural gas consump- end in structural failure. SCC is a type of and caustic environments, but not in

said: “Global natural gas consumption economic advantage over alternate tion in the country, the reliance on LNG environmentally assisted cracking (EAC), ammonia, whereas brasses crack in Fig. 2: Conditions necessary for occurrence

of SCC

is expected to witness modest growth, fuels, following the strong uptick in will, however, remain material. The caused by various factors combined ammonia-containing environments, but

given the focus of the major natural CNG vehicle sales in the last couple share of LNG in the gas mix is pro- with the environment surrounding the not in chlorides. are referred to as “the environment.”

gas consumers in regions of Euro- of years. The increasing adoption jected to increase from 48% in FY2024 pipeline. It occurs by a combination if This environment may be isolated

pean Union, Japan & Korea towards of electric vehicles in the passenger to 50% in FY2025. However, since corrosion and tensile stress. Corrosion The important variables affecting from the surrounding soil by the pipe

other sources of energy. Amidst these vehicle and bus segments will remain domestic production is expected to start is related to susceptibility of the material stress corrosion cracking are tempera- coating, and the conditions at the pipe

demand headwinds, the LNG capacity key threats for the CNG offtake. Addi- moderating from FY2028 onwards, the to the environment, while stresses may ture, Solution composition, metal com- surface may be different from those in

addition over the next four year, which tionally, ability of the CGD entities to reliance on LNG would further rise be residual, external or operational position, stress, and metal structure. the surrounding soil.

is equivalent to ~41% of the current ensure availability of CNG at competi- as India looks to increase the share of (1, 2, & 3). Cracking is accelerated by increasing

global LNG production capacity, is tive prices going forward will remain a natural gas in the energy mix. temperature. Most susceptible alloys The four factors controlling the for-

o

expected to result in a downward pressure What is SCC will begin cracking at 100 C. The pre- mation of the potent environment for

on the global LNG prices. India thus 250 56% 60% SCC refers to cracking caused by sence of dissolved oxygen or other oxi- the initiation of SCC are the type and

stands to benefi t in terms of availabi- 49% 48% 52% 50% 49% 49% the simultaneous presence of tensile dizing agents is critical to the cracking condition of the coating, soil, tempera-

lity of LNG at reasonable prices over 200 44% 50% of austenitic SS in chloride solutions ture and cathodic protection current

the medium term, notwithstanding the 40% and removal of oxygen will prevent the levels.

near-term volatility amid geo-political 150 30% attack.

tensions in West Asia.” 100 SCC often begins on the pipeline

20% Conditions that lead to SCC surface at areas where coating disbond-

Recovery in gas consumption 50 10% The occurrence of SCC depends on ment or coating damage occurs. The

India’s gas consumption, after wit- the simultaneous achievement of three ability of a coating to resist disbond-

nessing headwinds in FY2023 owing 0 0% conditions: a potent cracking environ- ment is a primary performance pro-

to the elevated LNG prices, recovered FY2021 FY2022 FY2023 FY2024 Q1FY2025 FY2025E FY2026E FY2027E ment; a material susceptible to SCC; perty of coatings and affects all forms

sharply to 187.9-mmscmd in FY2024 and a tensile stress higher than thresh- of external pipeline corrosion. Coatings

(~17% increase YoY) with easing of LNG Consumption old stress (Figure-2)(3). with good adhesion properties are gene-

LNG prices. Consumption in India Domestic gas consumption rally resistant to the mechanical action

is expected to grow by 6-8% YoY in % Share of LNG in consumption-RHS Fig. 1: Stress corrosion of type 304 stainless A potent cracking environment of soils from wet/dry cycles and freeze/

FY2025, supported by softer LNG Fig. 2: Trend in domestic and LNG consumption in India, mmscmd steel autoclave The conditions at the pipe surface thaw cycles. They also are better able to

182 Chemical Weekly September 10, 2024 Chemical Weekly September 10, 2024 183

Contents Index to Advertisers Index to Products Advertised