Page 204 - CW E-Magazine (26-9-2023)

P. 204

Special Report

test to check for leaks in pressure ves- of air), the amount of helium entering- The helium leak test method is sen-

sels before being placed into service through a leak and thus the sensitivity is sitive to all types of leaks. If leaks are

or during routine checks. It is useful increased by a factor of three compared detected as an overall examination,

because the test itself uses a pressurised to air. each tube and tube-to-tube sheet weld

liquid to determine whether a leak is can be tested individually by helium

present, somewhat replicating what the During a helium sniff test, the pres- leak test or by another NDT method.

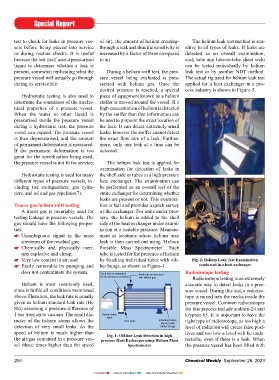

pressure vessel will actually go through sure vessel being evaluated is pres- The actual rig used for helium leak test

during its service life. surised with helium gas. Once the applied for a heat exchanger in a pro-

desired pressure is reached, a special cess industry is shown in Figure-2.

Hydrostatic testing is also used to piece of equipment known as a helium

determine the soundness of the mecha- sniffer is moved around the vessel. If a

nical properties of a pressure vessel. high concentration of helium is detected

When the water or other liquid is by the sniffer then that information can

pressurised inside the pressure vessel be used to pinpoint the exact location of

during a hydrostatic test, the pressure the leak. It can detect extremely small

vessel can expand. The pressure vessel leaks; however the sniffer cannot detect

is then depressurised, and the amount the exact flow rate of a leak. Further-

of permanent deformation is measured. more, only one leak at a time can be

If the permanent deformation is too detected.

great for the specification being used,

the pressure vessel is not fit for service. The helium leak test is applied for

examination for detection of leaks in

Hydrostatic testing is used for many the shell side or tubes in a high pressure

different types of pressure vessels, in- heat exchanger. The examination can

cluding fire extinguishers, gas cylin- be performed as an overall test of the

ders, and oil and gas pipelines(7). entire exchanger for determining whether

leaks are present or not. This examina-

tracer gas/helium sniff testing tion is fast and provides a quick survey

A tracer gas is invariably used for of the exchanger. For units under pres-

testing leakage in pressure vessels. The sure, the helium is added to the shell

gas should have the following proper- side of the heat exchanger under exami-

ties: nation at a suitable pressure. Measure-

Unambiguous signal in the mass ment at locations where helium may

spectrum of the residual gas; leak is then carried out using ‘Helium

Chemically and physically inert, Portable Mass Spectrometer’. Each

non explosive and cheap; tube is tested for the presence of helium

Very low content in air; and by blocking individual tubes with rub- Fig. 2: Helium Leak test Examination

Easily removable by pumping and ber bungs, as shown in Figure-1. conducted in a heat exchanger

does not contaminate the system. Each tube is examined radioisotope testing

for the presence of helium Shell-side pressurized Radioisotope testing is an extremely

with helium gas

Helium is most commonly used, accurate way to detect leaks in a pres-

since it fulfils all conditions mentioned sure vessel. During this test, a radioiso-

above.Therefore, the leak rate is usually tope is mixed into the media inside the

given as helium standard leak rate (He pressure vessel. Common radioisotopes

Std) assuming a pressure difference of for this process include sodium-24 and

1 bar from air to vacuum. The small dia- Helium mass krypton-85. It is important to have the

spec

meter of the helium atoms allows the Tube plate Individual tubes right type of radioisotope, as too high a

blocked with

detection of very small leaks. As the rubber bungs level of radiation will create false posi-

speed of helium is much higher than Fig. 1: off-line Leak detection in high tives and too low a level will be unde-

the air/gas contained in a pressure ves- pressure Heat Exchanger using Helium Mass tectable, even if there is a leak. When

sel (three times higher than the speed Spectrometer the pressure vessel has been filled with

204 Chemical Weekly September 26, 2023

Contents Index to Advertisers Index to Products Advertised