Page 187 - CW E-Magazine (15-10-2024)

P. 187

Special Report Special Report

Caustic soda and electric vehicles: Driving a batteries, making it essential to EV design.

Caustic soda plays a vital role in refi ning

sustainable future alumina, the precursor to aluminium. Ap-

proximately 100-kg of caustic soda is used

s the world increasingly shifts pounds infl uences the demand for HIRA SAEED for every tonne of alumina produced. With

its focus toward sustainability, caustic soda. ResourceWise aluminium consumption in the automotive

Athe growing interest in electric sector expected to surge by 25%, this will

vehicles (EVs) is illuminating the oft- Electrode coatings slurry and other of world extraction happens. According signifi cantly impact caustic soda demand.

overlooked yet crucial role of caustic production uses to the International Lithium Association As a fast-growing end-use for caustic soda,

soda. Uniform and stable coatings on bat- (ILiA), hard rock extraction accounts for the automotive industry’s shift toward

tery electrode surfaces are key to perfor- around 60% of global lithium production. electrifi cation is poised to drive substantial

Though a relatively minor input mance. Coatings combine materials – in- In this method, ore spodumene is mined growth in caustic soda consumption.

across a wide range of processes, includ- cluding solvents, binders, and conductive and processed to extract lithium. The

ing those involved in the production of additives – that have been mixed (usually ore – comprising 0.5-1% of lithium – is Emerging technologies for EVs

lithium-ion batteries, caustic soda is for several hours) until homogeneous. crushed and roasted, extracting metals Solid-state batteries represent a newer

becoming indispensable in the journey to Caustic soda solution is used to fi ne-tune with sulphuric acid, before neutralization technology for EVs. They are potentially

a greener future. These batteries power the pH of the electrode slurry. Contami- using caustic soda. Metals, including cal- safer due to their lack of fl ammable com-

EVs, which in turn help reduce emissions nants, residues, and impurities that build cium, magnesium, iron, and potassium, ponents, but they are not yet mainstream.

and lessen our dependence on fossil up around battery parts are cleaned us- are eliminated by progressive precipita- Source: ResourceWise The lithium-ion battery uses a liquid elec-

fuels. At fi rst glance, it may seem counter- ing caustic soda solution. Waste streams tion via pH adjustment before lithium trolytic solution to regulate the fl ow of

intuitive to declare the energy-intensive generated during battery production – carbonate (Li CO ) is yielded using Realizing refi neries: The reality the European Commission imposed on current, while a solid-state battery uses a

2

3

chlor-alkali process as a cornerstone of which can be acidic and/or alkaline – are sodium carbonate. Lithium has been commercially pro- Chinese EV batteries as of July mid-2024. solid electrolyte. A solid-state battery can

a greener future. This, however, under- neutralized using a caustic soda solution. duced since 1923. The surge in demand for bene-fi t from increased energy density,

scores the complexity of transitioning Lithium value chain complexity rechargeable batteries these past decades Overlooked: Demand for aluminium faster charging, and a longer life cycle.

to more sustainable technologies. Green Extracting lithium Sourcing lithium presents signifi cant has dramatically increased the need for this in EVs These would still require lithium, which

caustic soda – produced using renew- One method extracts lithium from challenges driven by environmental con- crucial resource. Its production has swelled Beyond batteries, EV market growth is requires caustic soda, among many other

able energy – is gaining traction among brine – salars or landlocked seas – con- cerns and geopolitical factors. Most of in tandem with rising demand. Despite driving increased demand for aluminium. chemicals, for extraction and processing.

manufacturers. However, widespread taining water reserves with a high salt the world’s lithium reserves are concen- concerns over sourcing, several projects EVs use up to 25-27% more aluminium Due to the wide variety of technologies

adoption remains an unviable option for concentration. Israel’s Dead Sea and the trated in the so-called ‘lithium triangle’. have been announced across the US and than traditional internal combustion en- and processes, quantifying the demand for

many buyers due to its higher cost. Yet, Great Salt Lake of Utah, for example, The triangle spans Argentina, Bolivia, Europe. Many of these initiatives, however, gine vehicles. This is largely due to the caustic soda and other materials used in the

even in its conventional form, caustic comprise up to a third of dissolved salt. and Chile, though China and Australia face possible delays or cancellations due need for lightweight components like production of batteries for electric vehi-

soda plays a crucial role in the broader They tend to have “high” lithium content and are also major producers. to funding constraints, market volatility, or e-drive housings, battery pack casings, and cles is challenging, and the outlook could

sustainability narrative. at 200-2,000 parts per million. supply chain issues. A notable example is cooling plates. Aluminium’s lighter weight change very rapidly as new innovations

In fact, the demand for Chinese the collaboration between Swedish battery compensates for the heavier lithium-ion arise.

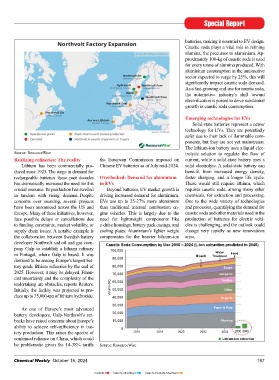

The role of caustic soda in EV production The process involves pumping brine liquid caustic soda exports is expected developer Northvolt and oil and gas com- Caustic Soda Consumption by Use 2016 – 2024 (L-ion extraction predicted to 2040)

Caustic soda use varies across diffe- from salars into artifi cial lakes in the to continue increasing due to Australia’s pany Galp to establish a lithium refi nery 100,000 Water

rent production processes, particularly desert where open-air evaporation can rapidly developing lithium battery in- in Portugal, where Galp is based. It was 90,000 Bleach Treatment Food

in the evolving EV industry. While raise lithium concentration by a hundred dustry. China plans to start up new caus- destined to be among Europe’s largest bat-

some methods rely heavily on it as a raw times or more when it can precipitate out tic soda capacities, including capacities tery-grade lithium refi neries by the end of 80,000 Soaps

material, most others use it primarily for as lithium carbonate. The use of caustic along the coast, which is expected to 2025. However, it may be delayed. Finan- 70,000 Inorganic

pH adjustment. The most conventional soda in this process is lower than for hard increase the supply for export. In Asia, cial uncertainty and the complexity of the 60,000 Textiles

EV uses a lithium-ion battery. The two rock mineral extraction. This alternative India and South Korea are also expanding undertaking are obstacles, reports Reuters. Volume (Kt)

main raw materials used for Li-ion method requires desert land nearby and caustic soda capacities this year, which Initially, the facility was projected to pro- 50,000 Other

batteries are lithium carbonate and is mostly confi ned to Chile, Argentina, will compete with Chinese goods. Aus- duce up to 35,000-tpa of lithium hydroxide. 40,000 Organic

lithium hydroxide. Bolivia, and China today. Pegmatite-type tralia’s import volume of liquid caustic 30,000

minerals – found in granite, including soda increased by 17% last year com- As one of Europe’s most advanced Paper & Pulp

Lithium carbonate is more cost- feldspar, mica, and quartz – are the forma- pared to 2022. This, according to our battery developers, Galp-Northvolt’s set- 20,000

effective and easier to handle due to its tions that underpin the method. Though China-based chlor-alkali expert Carol backs have raised concerns about Europe’s 10,000 Alumina

lower reactivity, while lithium hydro- Australia is the main source today, peg- Li, Senior Consultant ResourceWise ability to achieve self-suffi ciency in bat- 0

xide, though more reactive, offers supe- matites are found worldwide. Extraction Chemicals, is largely driven by demand tery production. This raises the spectre of 2016 2018 2020 2022 2024 2030 2040

rior performance in battery production. of lithium from the minerals, however, is increase from aluminium producers and continued reliance on China, which could Lithium-ion extraction

The choice between these two com- mainly centred in China, where over 75% the lithium battery industry. be problematic given the 14-38% tariffs Source: ResourceWise

186 Chemical Weekly October 15, 2024 Chemical Weekly October 15, 2024 187

Contents Index to Advertisers Index to Products Advertised