Page 182 - CW E-Magazine (24-10-2023)

P. 182

Special Report

(165°C, 2.5-3 MPa) is injected into the CHEmICAL LOOPINg COmbUSTION CONvERTER AbSORbER

deposit via the outermost tube. Sulphur Concentrated

(m.p. 115°C) melts and flows into the Steam turbine/ sulphuric acid

middle tube. Water pressure alone is generator SO 2

unable to force the sulphur into the Concentrated Vanadium Waste gas

SO 2 SO 2 + O 2 Oxide catalyst SO 3

surface due to the molten sulphur’s 450 C o

greater density, so hot air is introduced N 2 (+O 2 ) Mixer Oleum

via the innermost tube to froth the sul- Water H 2 S 2 O 7

Sulphuric

phur, making it less dense, and pushing acid, H 2 SO 4

it to the surface.

Air Sulphur Air

Compressed

air Fig. 4: Sulphur burning process

Molten

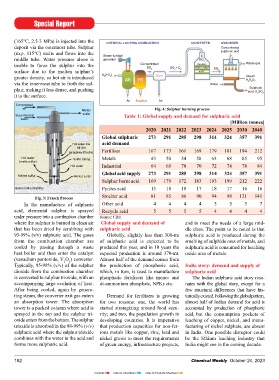

Superheated sulfur Table 1: Global supply and demand for sulphuric acid

water

[Million tonnes]

2020 2021 2022 2023 2024 2025 2030 2040

Global sulphuric 273 291 285 298 314 324 357 391

Hot water line acid demand

Air line

(air bubbles lift sulfur) Fertiliser 167 173 161 169 179 181 194 212

Hot water Sulfur tubing Metals 43 50 54 58 63 68 85 95

(melts sulfur)

Hot water Industrial 64 69 70 70 72 74 78 84

Global acid supply 273 291 285 298 314 324 357 391

Melted sulfur Melted sulfur

Sulphur burnt acid 169 179 172 183 193 199 212 222

Barren rock (anhydrite) Pyrites acid 15 18 18 17 18 17 16 16

Fig. 3: Frasch Process Smelter acid 81 85 86 90 94 98 121 141

In the manufacture of sulphuric Other acid 4 4 4 4 5 5 5 7

acid, elemental sulphur is sprayed Recycle acid 5 5 5 5 4 4 4 4

under pressure into a combustion chamber Source: CRU.

where the sulphur is burned in clean air Global supply and demand of and to meet the needs of a large mid-

that has been dried by scrubbing with sulphuric acid dle class. The point to be noted is that

93-99% (v/v) sulphuric acid. The gases Globally, slightly less than 300-mt sulphuric acid is produced during the

from the combustion chamber are of sulphuric acid is expected to be smelting of sulphide ores of metals, and

cooled by passing through a waste produced this year, and in 10 years the sulphuric acid is consumed for leaching

heat boiler and then enter the catalyst expected production is around 370-mt. oxide ores of metals.

(vanadium pentoxide, V O ) converter. Almost half of the demand comes from

2

5

Typically, 95-98% (v/v) of the sulphur the production of phosphoric acid, India story: demand and supply of

dioxide from the combustion chamber which, in turn, is used to manufacture sulphuric acid

is converted to sulphur trioxide, with an phosphatic fertilisers like mono- and The Indian sulphuric acid story reso-

accompanying large evolution of heat. di-ammonium phosphate, NPKs etc. nates with the global story, except for a

After being cooled, again by genera- few structural differences that have his-

ting steam, the converter exit gas enters Demand for fertilisers is growing torically existed. Following the global pattern,

an absorption tower. The absorption for two reasons: one, the world has almost half of Indian demand for acid is

tower is a packed column where acid is started strategizing around food secu- accounted by production of phosphoric

sprayed in the top and the sulphur tri- rity; and two, the population growth in acid, but the consumption pockets of

oxide enters from the bottom. The sulphur developing countries. It is imperative leaching of copper, nickel, and manu-

trioxide is absorbed in the 98-99% (v/v) that production capacities for non-fer- facturing of nickel sulphate, are absent

sulphuric acid where the sulphur trioxide rous metals like copper, zinc, lead and in India. One possible disruptor could

combines with the water in the acid and nickel grows to meet the requirements be the lithium leaching industry that

forms more sulphuric acid. of green energy, infrastructure projects, India might see in the coming decade.

182 Chemical Weekly October 24, 2023

Contents Index to Advertisers Index to Products Advertised