Page 169 - CW E-Magazine (26-11-2024)

P. 169

Special Report Special Report

production in electrolytic hydrogen pro- are styrene and ROCO-C-NOH and Sustainable twist – towards and electricity to make ethylene oxide/

duction; CO reduction, etc.) Extensive unconverted styrene can be recovered. highly atom effi cient Grignard ethylene glycol (EG) and propylene oxide/

2

research is earmarked on MOR with high (ACS Sustainable Chem. Eng., 2024, processes propylene glycol and have carried out a

Faraday effi ciencies. These authors have DOI: 10.1021/acssuschemeng.4c03621). techno-economic analyses. Gas diffusion

investigated the selectivity of MOR to P. Kohler et al have referred to Cu salts electrode assembly was used. At single

formate with progressing conversion at Combined methane cracking being highly toxic for aquatic life with pass, conversion was above 70% for EO

high current densities of up to 200 mA per for H production with devastating and long-lasting effects. and 40% for EG with overall Faradaic

2

sq. cm. on the electrodes referred above. CO utilised for catalyst Thus, elimination of Cu should be Effi ciencies (FE) above 20% and high

2

With optimisation, a formate yield of regeneration using dual welcome. In Grignard reactions, acyl carbon selectivities. Propylene conver-

70% at 100 mA per sq. cm. with an anodic functional nanostructured chlorides are widely used in combina- sion realises economic feasibility at a

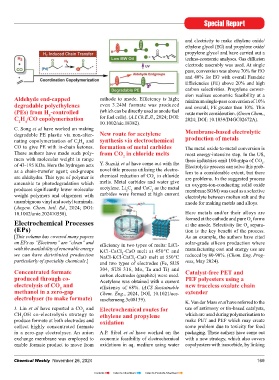

potential of 1.33V vs. reversible hydrogen particles tion with Cu(I) chloride to introduce Aldehyde end-capped cathode to anode. Effi ciency is high; minimum single-pass conversion of 10%

electrode (RHE). (Chem. Eng. Jl., 2024, acyl substitutes to aromatic compounds. degradable polyethylenes even 3.24M formate was produced and overall, FE greater than 10%. This

495, 1 Sep., 153000; DOI: 10.1016/j. Y-C Zeng et al have worked on the title These authors have demonstrated that (PEs) from H -controlled (which can be directly used as anode fuel route merits consideration. (Green Chem.,

2

cej.2024.153000). problem which allows CO to be used carboxylic acids anhydrides are a com- C H /CO copolymerisation for fuel cells). (A.I.Ch.E.Jl., 2024; DOI: 2024; DOI: 10.1039/D4GC02672A).

4

2

10.1002/aic.18382).

2

for converting carbon obtained from petent and highly selective alternative

Repulsion attractive for cracking of methane to CO. A Ni-based to acyl chlorides when used in the C. Song et al have worked on making New route for acetylene Membrane-based electrolytic

electrocatalysis absence of Cu(I) catalyst. The carboxy- degradable PE plastic via non-alter- production of metals

nating copolymerisation of C H and synthesis via electrochemical

late salt by-products are recycled via 2 4

R.V. Mom has reported that unravelling reaction with ketene thus eliminating CO to give PE with in-chain ketones. formation of metal carbides The metal oxide-to-metal conversion is

the key parameters that govern the acti- waste and heavy metal outgo. (Helv. These authors have made such poly- from CO in chloride melts most energy-intensive step. In the US,

2

vity of O evolution reaction catalysts Chim. Acta, 2024; DOI: 10.1002/hca. mers with molecular weight in range these industries emit 100-mtpa of CO .

2

2

is an essential step towards efficient 2024000487). of 43-195 KDa. Here the hydrogen acts Y. Suzuki et al have come out with the Electrolytic process can solve this prob-

production of green H . The repulsion as a chain-transfer agent; end-groups novel title process utilising the electro- lem to a considerable extent, but there

2

between adsorbates on the electrocata- Micelle-enabled Hofmann are aldehydes. This type of polymer is chemical reduction of CO in chloride are problems. In the suggested process

2

lyst surface has been recognised as a spherical nanoparticle cluster was deve- rearrangement in water amenable to photodegradation which melts. Metal carbides and water give an oxygen-ion-conducting solid oxide

powerful promoter for the rate-limiting loped for effective cyclic catalyst. 10 produces signifi cantly lower molecular acetylene. Li C and CaC as the metal membrane SOM) was used as a selective

2

2

2

O-O coupling step. (Nature Catalysis, Ni-1Ce/5Al allows high yield of H . X. Xing et al have converted a variety of weight polymers and oligomers with carbides were formed at high current electrolyte between molten salt and the

2024, 7, 757-758). This is achievable at remarkably low amides to the corresponding amines using unambiguous vinyl and acetyl terminals. anode for making metals and alloys.

2

(Angew. Chem. Intl. Ed., 2024; DOI:

Biphasic electrosynthesis of temperature of around 600°C. (ACS nanomicelles in water and without use of 10.1002/anie.202410558). Here metals and/or their alloys are

2-Isoxazol(in)e-3-carboxylates: Sustainable Chem. Eng., 2024; DOI: any solvent. Excellent yield up to 99% are Electrochemical Processes formed at the cathode and pure O forms

2

10.1021/acssuschemeng.4c04266).

Reaction optimisation from reported and was scaled-up and proved to (EPs) at the anode. Selectivity for O separa-

2

be robust. (Org. Proc. Res. Dev., 2024;

milligram to heterogram scale Advantageous properties of a DOI: 10.1021/acs.oprd.4c00197). [This column has covered many papers tion is the key benefi t of the process.

As an example, the authors have cited

Y. Nakamura et al have reported good new fungicide, isofetamid (I) on EPs as “Electrons” are “clean” and effi ciency in two types of melts: LiCl- solar-grade silicon production where

yields for the title reaction. The proposed Synthesis of peptides with the availability of renewable energy KCl-CaCl -CaO melt at 450°C and manufacturing cost and energy use are

2

strategy has been demonstrated by over S. Nishimi et al have reported a new by reactive extrusion: we can have distributed production NaCl-KCl-CaCl -CaO melt at 550°C reduced by 80-90%. (Chem. Eng. Prog-

2

30 highly functionalised and diverse fungicide and have assessed its fungal Application to the continuous particularly of speciality chemicals.] and two types of electrodes (Fe, SUS ress, May 2024).

examples. Even a derivative isoxadifen- spectrum, mode of action and effects and solventless preparation of 304, SUS 316, Mo, Ta and Ti) and

ethyl has been synthesised in a more on the infection process of Botrytis Aspartame (A) Concentrated formate carbon electrodes (graphite) were used. Catalyst-free PET and

sustainable way. The starting reactants Cinerea. Fungicidal activity against produced through co- Acetylene was obtained with a current PEF polyesters using a

isolates of B. Cinerea resistant existing T.M. El-Dine et al have carried out pep- electrolysis of CO and effi ciency of 68%. (ACS Sustainable new traceless oxalate chain

2

fungicide was studied. I tide synthesis in a twin-screw extruder. methanol in a zero-gap Chem. Eng., 2024, DOI, 10.1021/acs- extender

exhibited excellent fungi- No solvent was used, and excesses of electrolyser (to make formate) suschemeng.3c08139).

cide activity against starting material and reagents were K. Van der Mass et al have referred to the

ascomycetes; it had no avoided. This general method enabled the J. Lin et al have reported a CO and Electrochemical routes for use of antimony or tin-based catalysts,

2

activity against basidio- preparation of dipeptides and tripeptides CH OH co-electrolysis strategy to ethylene and propylene which are used during polymerisation to

3

mycetes and oomycetes. with no epimerisation. Aspartame, a produce formate at both electrodes and oxidation make PET and PEF which may create

(J. Pesticide Sci., 2024, synthetic dipeptide, was made in a conti- collect highly concentrated formate some problem due to toxicity for food

49, Issue 2, 130-134; nuous mode on large scale and with high in a zero-gap electrolyser. An anion A.P. Sibal et al have worked on the packaging. These authors have come out

DOI; 10.1584/jpesticide productivity. (Chemistry Europe, 2024, 2, exchange membrane was employed to economic feasibility of electrochemical with a new strategy, which also covers

D 23-067). issue 3-4; DOI: 10.1002/ceur.202400007). enable formate product to move from oxidations in aq. medium using water copolyesters with isosorbide, by linking

168 Chemical Weekly November 26, 2024 Chemical Weekly November 26, 2024 169

Contents Index to Advertisers Index to Products Advertised