Page 168 - CW E-Magazine (25-3-2025)

P. 168

Special Report Special Report

methanol was obtained using DSC. DMC Multi-scale screening of

is a solvent in Li battery and high purity is metal-organic frameworks

required. The purity of DMC was raised (MOFs) for one-step ethylene

from 96% to 99.845% and the single purifi cation in PSA processes

yield could reach 70%. (Chem. Eng. Res. [This column has covered some papers

Des., 208, August 2024, 209-216; DOI: on ethylene – ex naphtha/LPG/ethane

10.1016/j.chem.2024.07.004,). cracking – purifi cation from mixtures

Energy-effi cient design with acetylene, C H , and ethane, C H

2

2

6

2

sequences for the purifi cation by PSA; also, similarly for propylene.

This is due to high capital and energy

of styrene monomer from cost in the established cryogenic distil-

the pyrolysis oil of waste lation, after selective hydrogenation of

polystyrene C H to C H .].

2

2

4

2

D. Kim et al have worked on the title Y. Zhou et al have adopted a multi-scale

process of considerable importance hierarchical framework to select promi-

from circular economy viewpoint. The sing MOFs and design suitable P/VSA

direct-indirect sequence, which positions processes by combining property-based

the separation column of ethylbenzene material screening and model-based

and styrene monomer as the last step, is process optimisation. For 5/90/5 C H /

2

2

advocated, which results in 30% reduc- C H /C H feed mixture, the proposed

2

6

4

2

tion in the total utility consumption and method gave C H productivity of 0.158

4

2

a 37% reduction in the total annual cost mol/sq.m.per sec with lowest energy

compared to the direct-direct sequence consumption of 42.76 kWh per tonne.

that separates lighter components se- This would imply 80% saving in energy

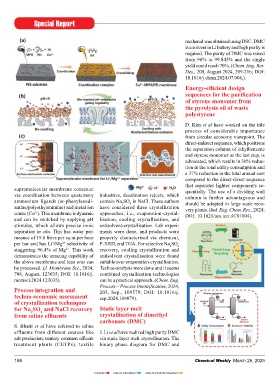

supramolecular membrane construct quentially. The use of a dividing wall

via coordination between quaternary industries, desalination rejects, which column is further advantageous and consumption compared to cryogenic

ammonium ligands (m-phenylenedi- contain Na SO in NaCl. These authors should be adopted in large scale reco- distillation. (A.I.Ch.E. Jl., 2024; DOI:

4

2

amine/polyethylenimine) and metal ion have considered three crystallisation very plants. (Ind. Eng. Chem. Res., 2024; 10.1002/aic.18544).

centre (Cu ). This membrane is dynamic approaches, i.e., evaporation-crystal- DOI: 10.1021/acs.iecr.4C01004). Infl uence of structural domain

2+

and can be switched by applying pH lisation, cooling crystallisation, and The CO working capacity evolution in carbon materials

stimulus, which allows precise ionic antisolvent-crystallisation. Lab experi- of Ni-MOF-74 and on the selective separation of

separation in situ. This has water per- ments were done, and products were corresponding operating alkenes from alkanes

meance of 19.8 litres per sq.m.per hour properly characterised via chemical, conditions for CO/N Sustainable isopropyl alcohol

per bar and has Li /Mg selectivity of P-XRD, and TGA. For selective Na SO adsorption separation (IPA) recovery via data-driven S. Du et al have worked on carbon

2

2+

+

4

2

staggering 96.4% of Mg . This work recovery, cooling crystallisation and active learning optimisation of molecular sieves for the title separa-

2+

demonstrates the amazing capability of antisolvent crystallisation were found Z. Wang et al have referred to the vacuum membrane distillation tion. They have elucidated the effect of

the above membrane and lean ores can suitable over evaporation-crystallisation. title adsorbent as the most promising (VMD) carbonaceous nanodomain evolution on

be processed. (J. Membrane Sci., 2024, Techno-analysis were done and it seems the pore sizes for selective sieving, using

708, August, 123035; DOI: 10.1016/j. combined crystallisation technologies candidates for CO (carbon monoxide) sucrose-based carbon molecular sieves

memsci.2024.123035). can be a practical approach. (Chem. Eng. adsorption. These authors have syste- J. Park et al have worked on the title (SUC-x). SUC-900 exhibited C H /C H

Process – Process Intensifi cation, 2024, matically studied this adsorption at process using polypropylene hollow 3 6 3 8

Process integration and 203, Sep., 109579; DOI: 10.1016/j. different test temperatures and pressure fi bre membranes to recover and reuse

techno-economic assessment sep.2024.109879). ranges by single-component static and IPA from wastewater. This study has

of crystallization techniques binary-component dynamic (CO/N , pioneered the utilization of active

2

for Na SO and NaCl recovery Static layer melt 50%/50% and 30%/70%, v/v) experi- learning-based Bayesian Optimisa-

2

4

from saline effl uents crystallisation of dimethyl ment; optimal conditions are mapped: tion (BO) to optimise the complex, separation with C H uptake of 2.0 mmol

3

6

carbonate (DMC) PSA at 100°C and 1.5 bar and a total multi-objective, and constrained VMD per gm at 1.0 bar and 25°C and negli-

S. Bhatti et al have referred to saline desorption pressure of 0.2 bar. Guidance process. The long-term stability was gible C H adsorption, achieving a mole-

3

8

effluents from different sources like J. Li et al have realized high purity DMC for process design is given. (Ind. Eng. studied. (ACS Sustainable Chem. Eng., cular recognition precision of 0.4A°.

salt production, tannery common effl uent via static layer melt crystallisation. The Chem. Res., 2024; DOI: 1021/acs.iecr. 2024; DOI: 10.1021/acssuschemeng. (ACS Sustainable Chem. Eng., 2024;

treatment plants (CETPs), textile binary phase diagram for DMC and 4C01188). 4C01285). DOI: 10.1021/acssuschemeng.4C01892).

168 Chemical Weekly March 25, 2025 Chemical Weekly March 25, 2025 169

Contents Index to Advertisers Index to Products Advertised