Page 178 - CW E-Magazine (17-6-2025)

P. 178

Special Report

quantities of gases emitted per THM. Hydrogen allocation cluding that generated during steam

All the data in the Table are in the basis The hydrogen use is divided as reforming.

of m /THM. follows: hydrogen obtained from COG

3

is used to produce methanol, and hydro- Case 2: Production of methanol only

The separation is done by selective gen obtained by reforming methane is To maximize the carbon utilisation

adsorption under moderate pressure. used for the production of ammonia. all the hydrogen and equivalent CO is

Other methods like membrane separa- utilized. The fi nal mass balance is given

tion are also available, however there is For convenience the available in the Table-5.

vast experience in adsorption methods C H were assumed as C H and

8

m

n

3

for decades. converted to CO and H through steam Table 5 indicates carbon utilization

2

reforming. of 28.6. At 95% yield, methanol pro-

The COG is compressed to approx. duction would be 9.53-kmol/THM or

5 bar pressure and fed to activated car- Production quantities 305-kg/THM. The capacity at 100%

bon adsorber separating all hydrogen, Based on the above-mentioned data utilisation would be 305x87.045=

and residual stream contains methane and assumptions, the ammonia and 26.55-mt; and at 50% utilisation it

along with other components. It is of methanol production quantities per would be 13.28-mt.

suffi cient purity to be used in methanol THM were calculated.

synthesis. The residual stream is com- * Ammonia production: 3.675 Power for gas separation

pressed and sent to steam reforming Kmoles/THM or 82.327-m /THM The separation processes, as men-

3

process, converting it into H and CO. (yield 97%). tioned, are done at low pressure of

2

The output from steam reforming then * Methanol production: 3.228 5-Barg, so that power consumption

goes to zeolite adsorption unit to sepa- Kmoles/THM or 72.309-m / THM is low, as the volumes are large. The

3

rate H from CO; the H is used for (yield 95 %). smaller volumes of separated gases

2

2

ammonia synthesis. can now be compressed to the pressure

The quantity of hydrogen pro- required by the process, which may

BFG is used only to the extent to duced by steam reforming is around be from 50-100 atm. The compression

obtain suffi cient nitrogen for ammonia 250-m /THM, which is more than power is calculated for the entire

3

synthesis. Thus, out of the 1,500-m / the hydrogen present in COG and volume of gases generated per THM,

3

THM, only 218-m /THM is used to BFG combined. There is a surplus of and the calculated power requirement

3

provide CO, CO and N . 438.51-m CO and 285.35-m CO in- is tabulated in Table-6.

3

3

2

2

2

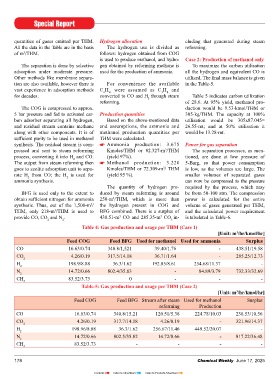

Table 4: Gas production and usage per THM (Case 1)

[Unit: m /hr/kmol/hr]

3

Feed COG Feed BFG Used for methanol Used for ammonia Surplus

CO 16.63/0.74 340.8/1,521 39.40/1.76 - 438.51/19.58

CO 4.26/0.19 317.5/14.18 36.71/1.64 - 285.25/12.73

2

H 198.9/8.88 36.3/1.62 192.85/8.61 254.68/11.37 -

2

N 14.72/0.66 802.4/35.83 - 84.89/3.79 732.33/32.69

2

CH 83.52/3.73 0 - - -

4

Table-5: Gas production and usage per THM (Case 2)

[Unit: m /hr/kmol/hr]

3

Feed COG Feed BFG Stream after steam Used for methanol Surplus

reforming Production

CO 16.63/0.74 340.8/15.21 120.51/5.38 224.78/10.03 236.53/10.56

CO 4.26/0.19 317.7/14.18 4.26/0.19 - 321.96/14.37

2

H 198.96/8.88 36.3/1.62 256.67/11.46 449.52/20.07 -

2

N 14.72/0.66 802.5/35.82 14.72/0.66 - 817.22/36.48

2

CH 83.52/3.73 - - - -

4

178 Chemical Weekly June 17, 2025

Contents Index to Advertisers Index to Products Advertised