Page 175 - CW E-Magazine (17-6-2025)

P. 175

Special Report

Steel plant gases for chemicals manufacture

and aiding carbon footprint reduction

hina is the largest steel producer methanol is economically viable, D.M. MOHUNTA & R. KISHEN

in the world followed by India. potentially to meet 16-34% of methanol Commercial Chemical and Deve-

CIndian steel industry has an market(4). lopment Co.

emission intensity of 2.55 tonnes of Email: dmm@ccdcindia.com

carbon dioxide (CO )/tonne of crude steel J. Lundgren et al.(5) have suggested

2

(tCO /tcs) whereas the global average various combinations of Blast Furnace Clean-up of COG

2

is1.85-tCO /tcs. The Indian steel sector Gas (BFG), COG, biogas, etc., for pro- COG is one of the three main pro-

2

contributes almost 12% to the country’s duction of methanol. Lingyan Deng cess gases obtained from steel plant

CO emissions, which is more than the and Thomas A. Adams II(6) conducted industries (the others being BFG and

2

global average. Approximately, 240-mt a feasibility study for ArcelorMittal Linze-Donnawitz gas (LDG)). It is pro-

of CO is emitted by the steel sector Dofasco Ontario (AMD), which demon- duced during coking, wherein coal is

2

each year, and given the Indian Govern- strated that the process of conversion heated in ovens to produce coke, which

ment’s infrastructure development of COG and BFG to methanol is effi - is used in the blast furnace for making

goals, it is expected to double by 2030(1). cient, and results in a net CO emis- iron. COG is a complex mixture

2

Decarbonising the steel industry has sions reduction of 228-ktpa (4.6% net (Table-1), and of the listed components,

been under active consideration for CO emission reduction) and can fi x hydrogen (H ), carbon monoxide

2

2

some time and various solutions have up to 246-ktpa of CO into methanol (CO), CO and unsaturated gases can

2

2

been suggested. annually. be present in the fi nal clean gas compo-

sition but others should be removed as

There are two sources of coke These and other examples indi- much as possible through a by-product

oven gases (COG): from integrated cate that India’s steel industry can not plant(2).

steel plants and independent coke only be a producer of steel but can

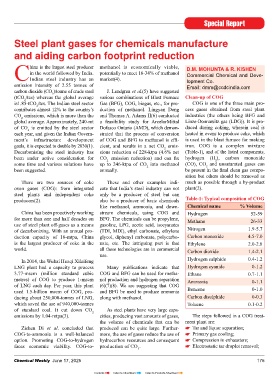

producers(2). also be a producer of basic chemicals Table-1: Typical composition of COG

like methanol, ammonia, and down- Chemical name % Volume

China has been proactively working stream chemicals, using COG and Hydrogen 52-59

for more than one and half decades on BFG. The chemicals can be propylene, Methane 26-33

use of steel plant off-gases as a means gasoline, LPG, acetic acid, isocyanates

of decarbonizing. With an annual pro- (TDI, MDI), ethyl carbonate, ethylene Nitrogen 1.9-5.7

duction capacity of 16-mtpa, China glycol, diphenyl carbonate, polycarbo- Carbon monoxide 4.5-7.0

is the largest producer of coke in the nate, etc. The intriguing part is that Ethylene 2.0-2.8

world. all these technologies are in commercial Carbon dioxide 1.4-2.1

use.

In 2014, the Wuhai Huaqi Xilaifeng Hydrogen sulphide 0.4-1.2

LNG plant had a capacity to process Many publications indicate that Hydrogen cyanide 0-1.2

3.77-mscm (million standard cubic COG and BFG can be used for metha- Ethane 0.7-1.1

metres) of COG to produce 1-mscm nol production and hydrogen separation Ammonia 0-1.1

of LNG each day. Per year, this plant (6)(7)(8). We are suggesting that COG

used 1.5-billion mscm of COG, pro- and BFG be used to produce ammonia Benzene 0-1.0

ducing about 250,000-tonnes of LNG, along with methanol. Carbon disulphide 0-0.3

which saved the use of 940,000-tonnes Toluene 0.1-0.2

of standard coal. It cut down CO As steel plants have very large capa-

2

emissions by 1.04-mtpa(3). cities, producing vast amounts of gases, The steps followed in a COG treat-

the volume of chemicals that can be ment plant are:

Zichen Di et al. concluded that produced can be quite large. Further- * Tar and liquor separation;

COG-to-ammonia is a well-balanced more, the use of gases reduce the use of * Primary gas cooling;

option. Promoting COG-to-hydrogen hydrocarbon resources and consequent * Compression in exhausters;

faces economic viability. COG-to- production of CO . * Electrostatic tar droplet removal;

2

Chemical Weekly June 17, 2025 175

Contents Index to Advertisers Index to Products Advertised