Page 183 - CW E-Magazine (9-7-2024)

P. 183

Special Report Special Report

calcium phosphate), a soil remediation lisers for product purifi cation is referred. lamine as a transesterifi cation catalyst Acetyl cello oligosaccharide – making tazobactam. Benefi ts of transition Every tonne of phosphoric acid gives 4-5

agent (citrate ions) and a binding agent The allylation reaction was carried out in co-accelerator and this has the lowest based block copolymers for from batch to continuous process are tonnes of PG. Their approach consists of

(chitosan). This product has been demon- reactive distillation column to separate dielectric loss of 0.0012 and the highest toughening cellulose triacetate highlighted. (Org. Proc. Res. Dev., 2024; lignite’s chemical looping gasifi cation

strated by soil experiments. A proof of the heavy boiling product from the con- breakdown strength of 42.26-kV/mm, (CA) poly (ε-caprolactone) DOI: 10.1021/acs.oprd.4c00020). with PG-based O carrier. The utilisation

2

concept is given, and soil-available P and densate/allyl alcohol mixture, which is and the highest tensile strength of (PCL) biodegradable blends of Ca in PG is via the low-temperature

P uptake are discussed and is better than then subjected for the recovery of allyl 93.7-MPa. The recovery can be done via Diazoacetonitrile (DAN) reductive decomposition of PG for pro-

commercial apatite. (Green Chem., 2023; alcohol. A techno-economic analysis mechanical hot pressing and regenerated S. Katsuhara et al have reported that DAN is a relatively stable diazo com- ducing CaO and CaCO . Two or more

3

DOI: 10.1039/D3 GC02859C). was done. (Ind. Eng. Chem. Res., 2024; through chemical degradation. Further, although CA is brittle it is a highly promi- pound, and its use has been overlooked. solid wastes are suggested to be used in

DOI: 10.1021/acs.iecr.3c03339). the degradable products can be directly sing next generation environmentally D. Boskovic et al have reported a micro- cement, bricks, etc. (Sepn. Purfn. Tech-

Plasma-based technology for used as curing accelerators. The recove- benign material. There are problems in fl ow process for the simultaneous process nol., 2024, 344, 20Sep., 127246; DOI:

sustainable textile functionali- Continuous flow nitration of red epoxy resin meets requirements. toughening CA. This work has repor- of making DAN in aqueous solution and 10.1016/J.seppur.2024.127246).

sation naphthalene (N) (Green Chem. 2024; DOI: 10.1039/ ted the design and synthesis of a block its extraction in CH Cl . Optimisation

2

2

D3GC 04580G). copolymer (BCP) consisting of cello was done and stable solution of DAN in Recovery of sulphuric acid and

M.P. Bailey has covered the title method, F. Xu et al have referred to the title oligosaccharide triacetate and PCL as a CH Cl is reported. (Chemie Ing. Tech., iron from TiO waste acid by

called the Ausora process, developed by reaction from the micro reactor to meso- Design of intensifi ed chemical 2 2 2

Xefco Pty. Ltd. (Australia), in association scale fl ow reactor and the safety issues processes for the production of compatibiliser for the CA-PCL blend. 2024; DOI: 10.1002/cite.202300187). membrane electrolysis com-

with additional institutions. A unique were investigated. The molar ratios of Films were made by solvent casting, M. Baldan et al have also reported bined with selective electro-

shower plasma process has been deve- HNO to N, residence time, reactive ethyl tert-butyl ether (ETBE) followed by hot pressing and these fi lms continuous synthesis of DAN; from dialysis

3

loped to produce coatings via plasma-en- temperature and H SO strength were had better mechanical properties than experiments to physical and Grey-Box [TiO made via leaching of ores with

2

4

2

hanced chemical vapour deposition at comprehensively studied. The reaction M. Gomez-Uchoa and A. Jimenez-Guti- those of neat CA and CA-PCL binary modelling. A micro-structural flow H SO leads to waste liquor containing

4

2

atmospheric pressure. This is a waterless yield could reach 94.96%; the maximum errez have given details of the proposed blend fi lms. (ACS Sus. Chem. Eng., 2024; reactor was used and a fl ow reaction acid and iron sulphate and their valori-

process and has water repellency and over temperature was only 3.78°C. EDC intensifi ed method for making ETBE, DOI: 10.1021/acssuschemeng.3c06416). calorimeter and appropriate data were sation is important.]

coloration for fi xing pigments. (Chem. was used a solvent. Comparison has been which can combine the benefi ts of blend- Plastic pyrolysis oils as feed- collected. [The above processes are

Eng. Magazine, Dec. 2023). made with the semi-batch reactor and ing gasoline with ethanol and valorisation stock for steam cracker based on diazotisation of NH CH CN.] F. Han et al have worked on ferrous ions

of isobutylene. The process consists of

2

present in the waste liquor. First, selec-

2

Development of a novel epoxy it is clear that continuous fl ow reactor one reactor and three conventional distil- [For circular economy one of the useful (Chemie Ing. Tech., 2024; DOI: 10.1002/ tive electrodialysis is employed to recover

cite.202300191).

resin has more advantages and economic lation columns. Three intensifi ed process ways is to carry out the pyrolysis of sulphuric acid. Then a three-chamber

benefi t, besides inherent safety. (Org.

waste LDPE/HDPE/PP etc. and use

M. Feigel et al have reported a useful Proc. Res. Dev., 2023; DOI: 10.1021/ alternatives have been developed, which the oil as a feed along with naphtha for Review of high-value utilisation membrane electrolysis was utilised to

use reactive distillation column (RDC),

oxidise Fe to Fe in the anode cham-

2+

3+

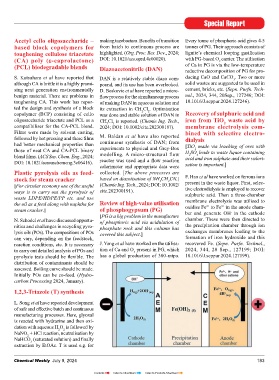

way of bridging the gap from labora- acs.oprd.3c00282). dividing wall column (DWC), and re- steam cracker.] of phosphogypsum (PG) ber and generate OH in the cathode

-

tory to production via adopting kinetic active dividing wall column (RDWC). [PG is a big problem in the manufacture chamber. These were then directed to

modelling-guided process development. An anhydride-cured degrad- RDWC gave the best economics. (Chem. N. Schodel et al have discussed opportu- of phosphoric acid via acidulation of the precipitation chamber through ion

The epoxy resin referred to is 1,2-ep- able epoxy insulating material Eng. Processing – Process Intensifi ca- nities and challenges in recycling pyro- phosphate rock and this column has exchanges membranes leading to the

oxy-6-methyl-triglycidyl-3,4,5-cyclo- exhibiting recyclability, reus- tion, 2024, 196, 109651; DOI 10.1016/j. lysis oils (POs). The compositions of POs covered this subject.] formation of iron hydroxide and this

hexane tricarboxylate. The reaction ability, and excellent electrical cep.2023.109651). can vary, depending on the feedstock, J. Yang et al have worked on the utilisa- recovered Fe. (Sepn. Purfn. Technol.,

steps begin with allyl sorbate and maleic performance reaction conditions, etc. It is necessary tion of Ca and O present in PG, which 2024, 344, 20 Sep., 127199; DOI:

anhydride via Diels-Alder allylation and Development of continuous fl ow to carry out detailed analysis of POs and has a global production of 300-mtpa. 10.1016/J.seppur.2024.127199).

2

epoxidation and these were simulated in Y. Wu et al have reported an anhy- process for the effi cient prepa- pyrolysis tests should be fl exible. The

Aspen Plus V12. A multi-tubular plug dride-cured epoxy, which can be recyc- ration of anti-TB specifi c drug, distribution of contaminants should be

fl ow reactor with downstream crystal- led. These authors have used triethano- TBAJ-876 assessed. Boiling curve should be made.

Initially POs can be co-feed. (Hydro-

carbon Processing 2024, January).

F. Gao et al have described the design,

development and scale up of a conti- 1,2,3-Triazole (T) synthesis

nuous fl ow process for the synthesis of

the title drug. This is reported at a 100-gm L. Song et al have reported development

reaction scale and the continuous of safe and effective batch and continuous

process reduced the reaction time and manufacturing processes. Here, glyoxal

was robust and amenable for scale-up. is reacted with hydrazine and then oxi-

Here the starting substance L1 is dation with aqueous H O is followed by

2

2

2,2,6,6-tetramethylpiperidine. (Org. NaNO + HCl reaction, neutralisation by

2

Proc. Res. Dev., 2024; DOI: 10.1021/ NaHCO (saturated solution) and fi nally

3

acs.oprd.3c00415). extraction by EtOAc. T is used e.g. for

182 Chemical Weekly July 9, 2024 Chemical Weekly July 9, 2024 183

Contents Index to Advertisers Index to Products Advertised