Page 182 - CW E-Magazine (2-7-2024)

P. 182

Special Report

specimen. The time taken for the sound

to traverse the thickness of a specimen

Receive socket Transmit socket

and return to the probe is usually dis-

LCD

played on an oscilloscope and refl ects

the distance the pulse has travelled and

thereby the thickness of the specimen.

Case

This technique is widely used for crack

detection and thickness monitoring of

Keypad Transducer in-service equipment that may suffer

from erosion-corrosion. Figure-16-A

shows the oscilloscope screen depict-

Sample block ing initial pulse, echo from the back

Battery compartment

(rear case) side of the specimen, and the echo from

the corrosion pit, using a normal probe.

Fig. 17: Direct reading ultrasonic thickness Fig. 18: Inspection Grid For UT Measurement Figure-16-B shows oscilloscope screen

gauge/meter In Pipe Bend

depicting echo from an internal crack in

the specimen, using an angle probe.

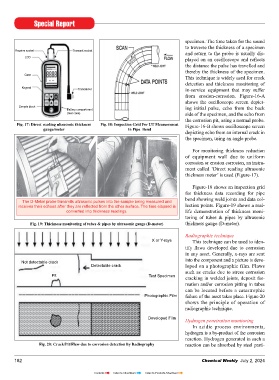

For monitoring thickness reduction

of equipment wall due to uniform

corrosion or erosion corrosion, an instru-

ment called ‘Direct reading ultrasonic

thickness meter’ is used (Figure-17).

Figure-18 shows an inspection grid

for thickness data recording for pipe

bend showing weld joints and data col-

The D-Meter probe transmits ultrasonic pulses into the sample being measured and

receives their echoes after they are refl ected from the other surface. The time elapsed is lection points. Figure-19 shows a real-

converted into thickness readings. life demonstration of thickness moni-

toring of tubes & pipes by ultrasonic

Fig. 19: Thickness monitoring of tubes & pipes by ultrasonic gauge (D-meter) thickness gauge (D-meter).

Radiographic technique

X or Y-rays This technique can be used to iden-

tify fl aws developed due to corrosion

in any asset. Generally, x-rays are sent

into the component and a picture is deve-

Not detectable crack

Detectable crack loped on a photographic film. Flaws

such as cracks due to stress corrosion

Pit Test Specimen cracking in welded joints, deposit for-

mation and/or corrosion pitting in tubes

can be located before a catastrophic

Photographic Film failure of the asset takes place. Figure-20

shows the principle of operation of

radiographic technique.

Developed Film

Hydrogen penetration monitoring

In acidic process environments,

hydrogen is a by-product of the corrosion

reaction. Hydrogen generated in such a

Fig. 20: Crack/Pit/Flaw due to corrosion detection by Radiography reaction can be absorbed by steel parti-

182 Chemical Weekly July 2, 2024

Contents Index to Advertisers Index to Products Advertised