Page 179 - CW E-Magazine (2-7-2024)

P. 179

Special Report Special Report

good results. Specimens can be exposed Actual plant tests are made when table or permanently installed instru- Some corrosion measurement tech- Typically, a corrosion measure- damaging process conditions exist,

in the pilot plant, and the equipment an operating plant is available. Interest ments to monitor corrosion rate/beha- niques can be used on-line, constantly ment, inspection and maintenance pro- which may result in corrosion-

itself is studied from the corrosion stand here is in evaluating better or more eco- viour of a running plant in order to exposed to the process stream, while gram used in any industrial facility will induced failure.

point. One possible disadvantage is that nomical materials or in studying corro- assess residual life of the equipment and others provide off-line measurement, incorporate the measurement elements Studying the correlation of changes

conditions of operation may widely be sion behaviour of existing materials as plan corrective maintenance actions. such as that determined in a laboratory provided by the four combinations of in process parameters and their

varied in attempting to determine the process conditions are changed. analysis. Some techniques give a direct on-line/off-line, direct/indirect mea- effect on system corrosivity.

optimum operation. Figure-6 shows Assessment of corrosion rate measure of metal loss or corrosion rate, surements. Diagnosing a particular corrosion

specimen rack for pilot-plant tests. Field tests are carried out with por- In most cases, aside from contami- while others are used to infer that a problem, identifying its cause and

nation problems, the primary concern is corrosive environment may exist. The commonly used corrosion moni- the rate controlling parameters,

the life (usually in years) of the equip- toring techniques used for asset integ- such as pressure, temperature, pH,

ment. A good corrosion-rate expression Corrosion monitoring is the prac- rity management in a process industry is fl ow rate, etc.

should involve: familiar units; easy cal- tice of measuring the corrosivity of shown in Figure-8. The summary of the Evaluating the effectiveness of a

culation with minimum opportunity for process stream conditions by the use methods with different classifi cations is corrosion control/prevention tech-

error; ready conversion to life in years; of “probes” which are inserted into the schematically described in Figure-9. nique such as chemical inhibition

penetration; and whole numbers with- process stream and continuously ex- and the determination of optimal

out cumbersome decimals. The widely posed to the process stream condition. The need for corrosion monitoring applications.

used expression is mils per year (mpy) Corrosion monitoring “probes” can be Corrosion monitoring techniques Providing management information

and is calculated according to the fol- mechanical, electrical, or electrochemi- can by: relating to the maintenance require-

lowing formula: cal devices. Providing an early warning that ments and ongoing condition of

plant.

Fig. 6: Specimen rack for pilot-plant tests Mils per year = (534 W) / (DAT), where: Visual/Optical

W = weight loss in mg Sentinel Hole Corrosion monitoring techniques

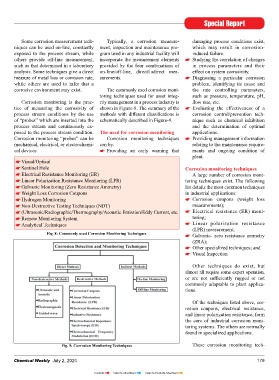

D = density of specimen, g/cm 3 Electrical Resistance Monitoring (ER) A large number of corrosion moni-

T = exposure time, hour Linear Polarization Resistance Monitoring (LPR) toring techniques exist. The following

Galvanic Monitoring (Zero Resistance Ammetry) list details the most common techniques

A rapid and ready conversion for Weight Loss Corrosion Coupons in industrial applications:

several expressions of corrosion rates Hydrogen Monitoring Corrosion coupons (weight loss

can be made by the monograph given Non-Destructive Testing Techniques (NDT) measurements);

in Figure-7. (Ultrasonic/Radiographic/Thermography/Acoustic Emission/Eddy Current, etc. Electrical resistance (ER) moni-

Remote Monitoring System toring;

Corrosion monitoring for asset Analytical Techniques Linear polarization resistance

integrity management (LPR) measurement;

Corrosion measurement is the quan- Fig. 8: Commonly used Corrosion Monitoring Techniques Galvanic- zero resistance ammetry

titative method by which the effective- (ZRA);

ness of corrosion control and preven- Other specialized techniques; and

tion techniques can be evaluated and Visual Inspection

provides the feedback to enable corro-

sion control and prevention methods to Other techniques do exist, but

be optimised. almost all require some expert operation,

or are not suffi ciently rugged or not

A wide variety of corrosion mea- commonly adaptable to plant applica-

surement and monitoring techniques tions.

Fig. 7: Monograph for mpy, ipy, ipm, and mdd exists as indicated in Table 2:

Of the techniques listed above, cor-

Table 2: Corrosion measurement and monitoring techniques rosion coupons, electrical resistance,

Non-Destructive Testing Analytical Chemistry Operational Data Fluid Electrochemistry and linear polarization resistance, form

Ultrasonic testing pH measurement pH Potential measurement the core of industrial corrosion moni-

Radiography Dissolved gas (O , CO , H S) Flow rate (velocity) Potentiostatic measurements toring systems. The others are normally

2

2

2

Thermography Metal ion count (Fe , Fe ) Pressure AC impedance found in specialized applications.

2+

3+

Eddy current/magnetic fl ux Microbiological analysis Temperature Fig. 9: Corrosion Monitoring Techniques These corrosion monitoring tech-

178 Chemical Weekly July 2, 2024 Chemical Weekly July 2, 2024 179

Contents Index to Advertisers Index to Products Advertised