Page 183 - CW E-Magazine (18-2-2025)

P. 183

Special Report Special Report

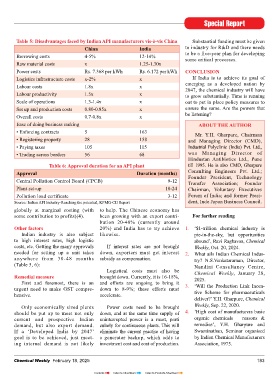

Table 3: China’s support to fermentation units Table 5: Disadvantages faced by Indian API manufacturers vis-à-vis China Substantial funding must be given

Development of ancillary Investor-friendly labour China India to industry for R&D and there needs

Infrastructure support Cost of utilities & capital Capacity industries for supplies laws Borrowing costs 4-5% 12-14% to be a five-year plan for developing

• Land at preferential • Local currency fi nance • Capacity has been • Effi cienct and • Workers can be hired some critical processes.

price ($10/sq.m.) with at average interest rate created taking continuous supply of and terminated as per Raw material costs x 1.25-1.30x

excellent connectivity to of 5% per annum. into account world maize/liquid glucose, company policy, without

ports and airports. • In summer, cost of demand. Thus, per unit which are basic raw interference of local Power costs Rs. 7.368 per kWh Rs. 6.172 per kWh CONCLUSION

• Located in areas where production may increase overheads, depreciation materials for fermentaion. government or labour If India is to achieve its goal of

temperature remains 8-9% compared to and operation costs are unions. Logistics infrastructure costs x-2% x

below 22°C for 9-10 winter, mainly due to use lower. • Effi ciency and company emerging as a developed nation by

months in a year. in utilities to maintain interests are top Labour costs 1.8x x

• Up to 100-MW power cooler temperature. priorities. 2047, the chemical industry will have

plant with steam and Labour productivity 1.5x x to grow substantially. Time is running

dual power transmission

lines. Scale of operations 1.3-1.4x x out to put in place policy measures to

• Common effl uent

treatment plant with Set up and production costs 0.80-0.85x x ensure the same. Are the powers that

30,000-tpd capacity. be listening?

Overall costs 0.7-0.8x x

Table 4: Issues & technological readiness with respect to production of fermentation-based products Ease of doing business ranking ABOUT THE AUTHOR

API Issues Technology Readiness • Enforcing contracts 5 163 Mr. Y.H. Gharpure, Chairman

Oxytetracycline Capital intensive, strain development/technology access Strains research and scale required. • Registering property 28 158 and Managing Director (CMD),

Tetracycline Capital intensive Strains research and scale required. • Paying taxes 105 115 Industrial Polyclinic (India) Pvt. Ltd.,

was Managing Director of

Ampicillin Total dependence on 6-APA, a KSM; fermentation-based Strains research and scale required. • Trading across borders 56 68 Hindustan Antibiotics Ltd., Pune

Cephalosporins Large scale fermentation capability, strain development/ Strains research required. Table 6: Approval duration for an API plant till 1985. He is also CMD, Gharpure

technology access Approval Duration (months) Consulting Engineers Pvt. Ltd.;

Penicillin G Large scale fermentation capability, strain development/ Strains research required. Central Pollution Control Board (CPCB) 9-12 Founder President, Technology

technology access Transfer Association; Founder

Streptomycin Strain development/technology access Strains research required. Plant set-up 18-24 Chairman, Voluntary Executives

Forum of India; and former Presi-

Pollution load certifi cate

Neomycin Strain development/technology access Strains research required. Source: Indian API Industry-Reaching the potential, KPMG-CII Report 3-12 dent, Indo Japan Business Council.

Doxycycline Strain development Strain research required. globally at marginal costing (with to help. The Chinese economy has

Vitamin C No viable cost-effective technology for KSM, 2-Keto-L- Viable technology for production of the KSM some contribution to profits)(4). been growing with an export contri- For further reading

gluconic acid, manufactured by microbial oxidation through microbial oxidation to be deve- bution 20-40% (currently around

loped. Other factors 20%) and India has to try achieve 1. ‘$1-trillion chemical industry is

Vitamin B12 Strain development Strains research required. Indian industry is also subject likewise. pie-in-the-sky, but opportunities

Erythromycin Non-availability of TIOC technology; large scale fermen- Technology for production of TIOC to be to high interest rates, high logistic abound’, Ravi Raghavan, Chemical

tation capability, strain development/technology access developed. costs, etc. Getting the many approvals If interest rates are not brought Weekly, Oct. 20, 2024.

Clarithromycin Strain development Strains research required. needed for setting up a unit takes down, exporters must get interest 2. What ails Indian Chemical Indus-

anywhere from 30-48 months subsidy as compensation.

Meropenem Local intermediate manufacturers are either small or Strains research required. (Table 5, 6): try? N.S.Venkataraman, Director,

depend on China; Strain development Logistical costs must also be Nandini Consultancy Centre,

Clindamycin Strain development/technology access Strains research required; viable technology Remedial measure brought down. Currently, it is 16-18%, Chemical Weekly, January 28,

2025.

for manufacture of API from KSMs available. First and foremost, there is an and efforts are ongoing to bring it 3. ‘Will the Production Link Incen-

Imipenem Strain development, inferior downstream processing Strains research required. urgent need to make GST compre- down to 8-9%; these efforts must tive Scheme for pharmaceuticals

Doripenem Strain development, inferior downstream processing Strains research required. hensive. accelerate. deliver?’ Y.H. Gharpure, Chemical

Potassium clavu- Large scale fermentation capability, strain development/ Strains research required. Only economically sized plants Power costs need to be brought Weekly, Sep. 22, 2020.

lanate/Clavulanic technology access should be put up to meet not only down, and at the same time supply of 4. ‘High cost of manufacturers basic

acid current and prospective Indian uninterrupted power is a must, parti organic chemicals – reasons &

Betamethasone Strain development/technology access Strains research required. demand, but also export demand. cularly for continueous plants. This will remedies’, Y.H. Gharpure and

Prednisolone Strain development/technology access Strains research required. If a ‘Developed India by 2047’ eliminate the current practise of having Swaminathan, Seminar organised

Dexamethasone Strain development/technology access Strains research required. goal is to be achieved, just meet- a generator backup, which adds to by Indian Chemical Manufacturers

ing internal demand is not likely investment cost and cost of production.

Source: APIs -Status, Issues, Technology Readiness and Challenges, TIFAC, July 2020 Association, 1975.

182 Chemical Weekly February 18, 2025 Chemical Weekly February 18, 2025 183

Contents Index to Advertisers Index to Products Advertised