Page 169 - CW E-Magazine (20-2-2024)

P. 169

Special Report Special Report

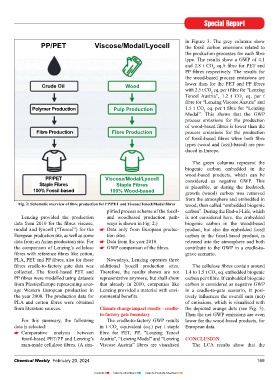

Carbon footprints of Lenzing’s viscose, modal PP/PET Viscose/Modal/Lyocell in Figure 3. The grey columns show

the fossil carbon emissions related to

and lyocell fi bres the production processes for each fi bre

type. The results show a GWP of 4.1

ellulose is a key structural com- of Lenzing’s man-made cellulose and 2.8 t CO eq./t fi bre for PET and

2

ponent of cell walls of plants staple fi bres viscose, modal and PP fi bres respectively. The results for

Cand trees, and therefore a wood- lyocell, produced in Europe and the wood-based process emissions are

based and in a wider sense bio-based Asia. Crude Oil Wood lower than for the PET and PP fi bres

material. Cellulose fi bres are used for Identify the environmental advan- with 2.5 t CO eq. per t fi bre for “Lenzing

2

a wide range within textile, nonwoven tages and disadvantages of man- Tencel Austria”, 1.2 t CO eq. per t

2

and other industrial applications, rang- made cellulose fi bres compared to fi bre for “Lenzing Viscose Austria” and

ing from home textiles over apparel tex- cotton, bio-based polylactic acid Polymer Production Pulp Production 1.5 t CO eq. per t fi bre for “Lenzing

2

tiles to technical textiles with very high (PLA) fi bres and fossil-based poly- Modal”. This shows that the GWP

property demands like tyre cord. The ethylene terephthalate (PET) and process emissions for the production

Life Cycle Assessment (LCA) study exa- polypropylene (PP) fi bres. For fi bre of wood-based fi bres is lower than the

mined the three types of wood-based comparison, fibres with similar Fibre Production Fibre Production process emissions for the production

cellulose staple fi bres that the company properties to the cellulose fi bres of fossil-based fi bres when both fi bre

Lenzing, a world leading and globally were chosen. types (wood and fossil-based) are pro-

active company with headquarters in duced in Europe.

Austria, can produce – viscose, modal In the goal and scope phase the fol-

and lyocell fi bres. lowing aspects were defi ned: The green columns represent the

Fig. 1: Cellulose staple fi bres Functional unit: 1 t staple fi bre. biogenic carbon embedded in the

Lenzing produces the three fi bre Lenzing, Photographer: Markus Renner System boundaries: cradle-to-factory PP/PET Viscose/Modal/Lyocell wood-based products, which can be

types – viscose, modal and lyocell – K. Patel from the Copernicus Institute of gate. Staple Fibres Staple Fibres considered as negative GWP. This

which are sold under the brand names Utrecht University conducted a Life Impact categories: Global Warming 100% Fossil-based 100% Wood-based is plausible, as during the feedstock

of TENCEL™ (lyocell and modal) and Cycle Assessment (LCA) of man-made Potential 100 (GWP100a), cumula- growth (wood) carbon was removed

LENZING™ ECOVERO™ (viscose) cellulose fi bres viscose, modal and tive energy demand, non-renewable from the atmosphere and embedded in

in textiles, respectively, and VEO- lyocell from Lenzing. In the study the energy use (among others). Fig. 2: Schematic overview of fi bre production for PP/PET and Viscose/Tencel/Modal fi bres wood, then called “embedded biogenic

CEL™ (lyocell, viscose) in nonwovens fi bres were named as follows: Viscose Impact assessment method: CML plifi ed process scheme of the fossil- carbon”. During the End-of-Life, which

business. The fi bres differ in terms of fibre as “Lenzing Viscose”, modal 2000 baseline method. Lenzing provided the production and woodbased production path- is not considered here, the embedded

their technical as well as haptical and fi bre as “Lenzing Modal” and lyocell data from 2010 for the fi bres viscose, ways is shown in Fig. 2.) biogenic carbon in the wood-based

optical properties due to their different fi bre as “Tencel”. Nowadays, Tencel The system boundaries start at the modal and lyocell (“Tencel”) for the Data only from European produc- product, but also the embedded fossil

production processes. is the trademark for lyocell and modal extraction of raw materials from the European production site, as well as some tion sites. carbon in the fossil-based product, is

fi bres and the nomenclature used in the environment (cradle). At that time, Lenz- data from an Asian production site. For Data from the year 2010. released into the atmosphere and both

The viscose fi bre is produced in a study is not anymore in line with cur- ing used wood only from FSC certifi ed the comparison of Lenzing’s cellulose GWP comparison of the fi bres. contribute to the GWP in a cradle-to-

conventional viscose process. Gene- rent branding. However, here the nam- wood suppliers. Nowadays, Lenzing fi bres with reference fi bres like cotton, grave scenario.

rally, viscose production is energy- ing from the peer-reviewed LCA study operates also other pulp mills and uses PLA, PET and PP fi bres, also for those Nowadays, Lenzing operates three

intensive and requires large quantities is used for the results of the study so PEFC certifi ed wood, too. Additionally, fi bres cradle-to-factory gate data was additional lyocell production sites. The cellulose fi bres contain around

of chemicals such as caustic soda and the reader is able to compare the results Lenzing only uses wood with a quality collected. The fossil-based PET and Therefore, the results shown are not 1.4 to 1.5 t CO eq. embedded biogenic

2

sulphuric acid. The modal fi bre is pro- of this summary with the original LCA which is unable to be used in furniture PP fi bres were modelled using datasets representative anymore, but shall show carbon per t fi bre. If embedded biogenic

duced in a modifi ed viscose process, study. so the wood for the fi bres does not com- from PlasticsEurope representing aver- that already in 2010, companies like carbon is considered as negative GWP

resulting in higher wet modulus fi bres. pete with the need of wood for other age Western European production in Lenzing provided a material with envi- in a cradle-to-gate scenario, it posi-

The lyocell fi bre is produced with the The LCA study was reviewed by high valued products. the year 2000. The production data for ronmental benefi ts. tively infl uences the overall sum (net)

lyocell process, which uses less sol- three external and independent experts. PLA and cotton fi bres were obtained of emissions, which is visualised with

vents and was commercialised in the The reviewers verifi ed that the LCA In the next process step at Lenzing’s from literature sources. Climate change impact results – cradle- the depicted orange dots (see Fig. 3).

early 1990s. Nowadays, all three types was conducted accordingly to the stan- production site in Europe, the wood is to-factory gate boundary Then the net GWP emissions are even

of fi bres are produced simultaneously dards of LCA (ISO 14040/14044). processed to cellulose pulp. Finally, For this summary, the following The cradle-to-factory GWP results lower for the wood-based products, for

in large quantities. the cellulose pulp is transformed into data is selected: in t CO equivalent (eq.) per t staple European data.

2

The goals of the peer-reviewed cellulosic fi bres in Lenzing’s viscose, Comparative analysis between fi bre for PET, PP, “Lenzing Tencel

LCA of cellulose fi bres LCA study were modal and lyocell processes (factory fossil-based PET/PP and Lenzing’s Austria”, “Lenzing Modal” and “Lenzing CONCLUSION

In 2010, Li Shen and Martin Identify the environmental impacts gate). man-made cellulose fi bres. (A sim- Viscose Austria” fi bres are visualised The LCA results show that the

168 Chemical Weekly February 20, 2024 Chemical Weekly February 20, 2024 169

Contents Index to Advertisers Index to Products Advertised