Page 183 - CW E-Magazine (26-12-2023)

P. 183

Special Report Special Report

End-of-life Li-ion battery sustainability: Its crucial tract the valuable metals in the black

mass, producing battery-grade metal

role over the coming years salts (e.g., lithium carbonate, cobalt

sulphate). These can then be processed

further to manufacture precursor for

ithium-ion (Li-ion) batteries are characteristics to CONRAD NICHOLS cathode active material for new bat-

used ubiquitously in daily life, Li-ion, without teries. This is considerably cheaper

Land the demand for Li-ion bat- the use of lithium Technology Analyst, IDTechEx than manufacturing new cathodes from

teries has continued to increase over or cobalt. Alter- hazardous electrolyte into the environ- virgin materials, and several life cycle

the last decade, including in consumer natively, redox ment and would waste the potential analyses in the literature suggest that,

electronics and portable devices, elec- fl ow batteries remaining value or materials contained in most cases, this causes less environ-

tric vehicles (EVs), and stationary can make use within the battery. mental impact too.

energy storage systems. EVs have been of cheaper and

responsible for most of this growth and more widely available materials such Repurposing (or remanufacturing) Pyrometallurgical processing typi-

is now the sector responsible for the as zinc, iron, or organic compounds, batteries for second-life applications cally occurs in a shaft furnace and is

largest percentage of total global Li-ion though the majority of deployments are typically sees Li-ion batteries from EVs a high-energy process that produces

battery demand, with IDTechEx fore- based on vanadium electrolytes. being reused in stationary energy stor- a mixed metal alloy, as well as a slag

casting the market for EV batteries age applications. This looks to maxi- stream typically containing lithium,

to exceed US$380-bn by 2034. However, while technologies such mize the value of the battery by using it manganese, and aluminium. These inter-

as these can diversify material demand in another less demanding application. mediaries would require further hydro-

As the demand for Li-ion batteries to more widely available and poten- metallurgical processing if all valuable

increases, so does the need to manage tially less environmentally problematic Recycling Li-ion batteries looks metals were to be recovered.

their sustainability throughout their en- ones, Li-ion demand is forecast to to recover valuable materials, which

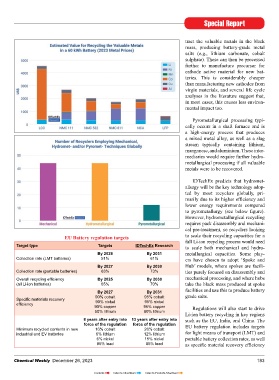

tire lifecycle, including raw material continue growing at a rapid pace. As either form part of the cell or other com- IDTechEx predicts that hydromet-

extraction and processing, battery use such, Li-ion material supply and EOL ponents of the battery pack. Recycling allurgy will be the key technology adop-

or reuse and, importantly, at end-of-life management will remain critical. will be important for battery manufac- ted by most recyclers globally, pri-

(EoL). Some of these factors have also turers looking to mitigate against poten- marily due to its higher effi ciency and

been a driving force behind the deve- Li-ion at end-of-life tial future raw material supply con- lower energy requirements compared

lopment of alternative energy storage Once a Li-ion battery has reached straints, fl uctuating raw material prices, to pyrometallurgy (see below fi gure).

technologies, in particular, in reducing the end of its fi rst life, several options and to domesticate material supply. However, hydrometallurgical recycling

the chance of supply bottlenecks to can be considered. These include dis- requires pack disassembly and mechani-

materials such as lithium, cobalt, and posal, recycling, or repurposing for Li-ion battery recycling cal pre-treatment, so recyclers looking

nickel. second-life applications. Li-ion battery recycling typically EU Battery regulation targets to scale their recycling capacities for a

sees recyclers extracting materials such full Li-ion recycling process would need

Na-ion batteries, for example, can Disposing of Li-ion batteries could as lithium, cobalt, nickel, manganese, Target type Targets IDTechEx Research to scale both mechanical and hydro-

offer relatively similar performance result in the leaking of fl ammable and copper, and aluminium. The techno- By 2028 By 2031 metallurgical capacities. Some play-

logies used in Li-ion battery recycling are Collection rate (LMT batteries) 51% 61% ers have chosen to adopt ‘Spoke and

typically a combination of mechanical, By 2027 By 2030 Hub’ models, where spokes are facili-

hydrometallurgical or pyrometallurgical Collection rate (portable batteries) 63% 73% ties purely focused on disassembly and

processing steps. Overall recycling effi ciency By 2025 By 2030 mechanical processing, and where hubs

(all Li-ion batteries) 65% 70% take the black mass produced at spoke

Mechanical processing is employed By 2027 By 2031 facilities and use this to produce battery

prior to hydrometallurgical processing. 90% cobalt 95% cobalt grade salts.

Once a recycler receives a battery pack, Specifi c materials recovery 90% nickel 95% nickel

effi ciency

this would require disassembling to 90% copper 95% copper Regulations will also start to drive

obtain the individual Li-ion cells. These 50% lithium 80% lithium Li-ion battery recycling in key regions

can then be mechanically crushed, 8 years after entry into 13 years after entry into such as the EU, India, and China. The

forming powder known as black mass. force of the regulation force of the regulation EU battery regulation includes targets

Minimum recycled contents in new 16% cobalt 26% cobalt

industrial and EV batteries 6% lithium 12% lithium for light means of transport (LMT) and

Hydrometallurgical processing uses 6% nickel 15% nickel portable battery collection rates, as well

chemical reagents to selectively ex- 85% lead 85% lead as specifi c material recovery effi ciency

182 Chemical Weekly December 26, 2023 Chemical Weekly December 26, 2023 183

Contents Index to Advertisers Index to Products Advertised