Page 192 - CW E-Magazine (28-11-2023)

P. 192

Special Report Special Report

is organic manure not being produced boost the production of ethanol, as it is tists used marine cellulolytic bacteria plementing such solutions. Since the

in large scale, utilising the millions of targeting to increase ethanol blending for hydrolysis, and fermentation was paddy straw are cut and removed in a

tonnes of paddy straw available? Ina- with petrol to the level of 20%. Seve- done with an isolated yeast strain. They period of 2-3 weeks, adequate storage

de-quate supply chain management, to ral incentives have been announced to claim that 100-kg of paddy straw can facilities are required. Since it would

produce manure and facilitate transpor- boost production of ethanol, and the produce 36-litres of ethanol, while the be expensive to transport paddy straw

tation to consumers, is one reason. Government has even permitted food same quantity of wheat stalk can pro- over long distance, it is necessary to

grains such as rice and maize to be used duce 53-litres. promote the facilities to use it at proxi-

Huge demand for briquettes for use as feedstock for production of ethanol. mate distance to the farm areas. The

as fuel Though some steps have been taken power, cement, fertiliser and chemical

Paddy straw can also be used as fuel To achieve the target of 20% blend- to produce ethanol from biomass, it is units have to be encouraged to utilise

in brick kilns, power plants, cement ing by 2025, it is estimated that about surprising that they do not use paddy the paddy straw for production of

units and industrial boilers, by convert- 1,016-crore litres of ethanol would be straw. manure, briquettes and ethanol. These

ing it into the form of pellets/briquettes. required. In addition, about 334-crore units may be provided the responsibi-

litres of ethanol would also be required What is the way out? lity and authority for cutting the paddy

Briquetting is the process of con- for other uses. It appears that this quan- Millions of tonnes of paddy straw straw from the fi elds, after paying a

verting low bulk density agricultural upon the regional demand-supply sce- October 2022. However, the power tum of ethanol would not be available are available in a short period of 2-3 nominal fee to the farmers. Such an

materials, such as paddy straw, into a nario. The Ministry of New and Renew- plants have been lagging in doing so from conventional sources. weeks, which is now largely burnt. arrangement would be a win-win situ-

solid fuel with high density. Briquettes able Energy (MNRE) estimates about because of inadequate supply of bri- ation for both the paddy growers as

are formed using high mechanical pres- 270-mt of agricultural waste, including quettes. In FY21, only eight power Paddy straw, which is available in The solutions pointed out need to be well as user industries. New Delhi and

sure without the use of chemical bin- paddy straw, is annually available in plants had co-fi red biomass pellets, and large quantity, however, can be used implemented as fast as possible, with nearby regions would also be saved

ders Packing paddy straw into briquette India, which can produce 28,000-MW this number has risen to 39 now. To put as feedstock for augment ethanol pro- effi ciency. Supply chain management from the annual pollution hazard.

raises the bulk concentration of paddy of power. About 800-kg of paddy straw the number in perspective, India has duction, and the technology to do so is is the crucial need.

straw, reduces its transportation cost, based briquettes can replace a 1,000-kg around 180 thermal power plants. commercially available. The Governments of Punjab, Haryana

and makes it easy to store. of coal. The concerned States – includ- and Uttar Pradesh have a crucial role

Apart from power plants, paddy Making ethanol is essentially break- ing Punjab, Haryana, Uttar Pradesh – to play in coordinating the activities

Briquettes provide much more heat, The Union Environment Ministry straw briquettes can be used profi tably ing down the complex sugars contained should jointly promote an organisa- for optimum supply chain management

emit fewer than 50% of the particulate has also announced a scheme to incen- in cement plants. Many cement units into simple sugars and then converting tion, with the object of facilitating the practices for paddy stubble.

matter and only a fraction of the ash tivise entrepreneurs to manufacture are eager to use briquettes as fuel due it into ethanol through fermentation. collection of paddy straw; its use as

from burning an equivalent amount of briquettes from paddy stubble. to their several advantages, but unable Scientists at the Indian Institute of manure in agriculture; for conversion One hopes that in the last quarter of

coal. to do so due to supply constraints. Science (IISc), Bangalore, have develo- into briquettes for use as fuel; and for 2024, the stubble burning issue would

In October 2021, the Power Ministry ped a pre-treatment process that helps production of ethanol. There are no no more be a live issue. The ball is

The price of briquette fuel produced decreed that all thermal power plants Use of paddy straw as feedstock for hydrolysis and fermentation. The scien- technology or investment issues in im- clearly in the court of governments!

from paddy straw is in the range of should ensure that at least 5% of bioethanol

Rs. 5,800 to Rs. 6,500 per tonne, depending coal used is mixed with biomass by Government of India is looking to Chemical Weekly | Import-Export Data

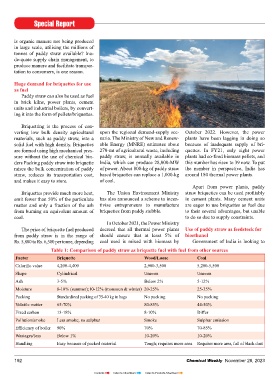

Table 1: Comparison of paddy straw as briquette fuel with fuel from other sources Market Surveys | Directories

Factor Briquette Wood/Loose Coal

Calorifi c value 4,200-4,400 2,900-3,500 5,200-5,500 Business Forums | Expositions

Shape Cylindrical Uneven Uneven The only organisation in India catering exclusively to the needs of the entire chemical industry

Ash 3-5% Below 2% 5-12%

Moisture 8-10% (summer);10-12% (monsoon & winter) 20-25% 25-35% Contact:

Packing Standardized packing of 35-40 kg in bags No packing No packing SEVAK PUBLICATIONS PVT. LTD.

Volatile matter 65-70% 80-85% 44-50% 602-B, Godrej Coliseum, K.J. Somaiya Hospital Road,

Fixed carbon 13-18% 8-10% Differ Behind Everard Nagar, Sion (E),

Pollution/smoke Less smoke; no sulphur Smoke Sulphur emission Mumbai 400 022.

Effi ciency of boiler 90% 70% 70-85%

Wastages/loss Below 1% 10-20% 10-20% Phone: +91-22-24044471 / 72

Handling Easy because of packed material Tough; requires more area Requires more area, full of black dust Email: admin@chemicalweekly.com

192 Chemical Weekly November 28, 2023 Chemical Weekly November 28, 2023 193

Contents Index to Advertisers Index to Products Advertised