Page 133 - CW E-Magazine (7-1-2025)

P. 133

Point of View

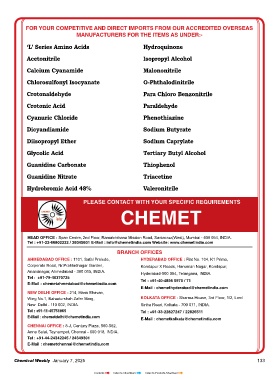

FOR YOUR COMPETITIVE AND DIRECT IMPORTS FROM OUR ACCREDITED OVERSEAS

MANUFACTURERS FOR THE ITEMS AS UNDER:-

as the critical raw material for making purified terephthalic acid (PTA), needed to make polyester fibre, filament yarn and bottle grade resin

(PET). To date, the refinery is the only producer of ortho-xylene (OX), required for making phthalic anhydride that goes into the manufacture of ‘L’ Series Amino Acids Hydroquinone

plasticisers, among other uses.

Acetonitrile Isopropyl Alcohol

The refinery was also conceived with a high severity fluidised catalytic cracker (FCC), with a ~10% propylene yield. This served as monomer

for downstream polypropylene (PP) at compelling cost-economics. The Delayed Coker – amongst the largest in the world – employs severe Calcium Cyanamide Malononitrile

thermal cracking to convert low value heavier residues to higher value light products with rejection of metals into the petcoke coproduced. The

recovery of some of these metals – vanadium and titanium, in particular – is a task that is yet to be taken up. The gasification complex – also the Chlorosulfonyl Isocyanate O-Phthalodinitrile

world’s largest – converts this low-value petcoke to usable, high-value fuel (synthetic natural gas, SNG), making Jamnagar energy-efficient and

self-sufficient in meeting its power and utilities requirement. The Refinery Off-Gas Cracker (ROGC) produces up to 1.7-mtpa of ethylene, which Crotonaldehyde Para Chloro Benzonitrile

feeds into downstream plants for polyethylenes at attractive cost-economics.

Crotonic Acid Paraldehyde

Oil to chemicals – the next stage

The chemicals focus of the refinery is slated to increase in line with plans amongst other refining majors globally. As several studies have Cyanuric Chloride Phenothiazine

pointed out, petrochemicals already represent the fastest growing use for crude oil. Though sustainability pressures on plastics will have an impact

on demand for virgin polymers, markets for petrochemicals, as a whole, will continue to expand for the foreseeable future in India, though not Dicyandiamide Sodium Butyrate

perhaps at the fast clip of the past few decades.

Diisopropyl Ether Sodium Caprylate

While a typical naphtha cracker operating downstream of a refinery processes about 8-10% of crude oil for chemicals, tighter integrated schemes

such as that practiced by RIL in Jamnagar take the chemical conversion potential up to 17-20%. Newer greenfield oil-to-chemical (O2C) projects Glycolic Acid Tertiary Butyl Alcohol

aim to valorise up to 40-60% for chemicals. Jamnagar has some way to go in this respect.

Guanidine Carbonate Thiophenol

About four years ago, there was a plan to carve out the key oil and petrochemicals assets, including those in refining, fuel retail and aviation fuel,

into a separate unit. This was widely seen as a precursor to a stake sale to Saudi Aramco, the world’s largest oil producer, but that has not panned out. Guanidine Nitrate Triacetine

New energy initiatives Hydrobromic Acid 48% Valeronitrile

For now, the Jamnagar site is also being repurposed to locate the new energy initiatives of RIL, including the integrated manufacture of

polysilicon, silicon wafers, photovoltaic cells as well as solar panels. Investments are also being made into integrated battery manufacturing,

including the well-established lithium ion and the emerging sodium ion. Green hydrogen manufacturing is also a priority, with substantial investments PLEASE CONTACT WITH YOUR SPECIFIC REQUIREMENTS

allocated for electrolyser manufacturing, with aim of hitting a manufacturing cost of $1 per kg of green hydrogen. While there are many who doubt

this target is feasible, getting anywhere close will count as no mean achievement. The hydrogen so produced is expected to be used to make green CHEMET

fuels – e.g., green methanol using captured carbon dioxide, and other green fuels.

This reinvention of a classic refinery-petrochemical complex to a new energy hub is a mammoth and complex exercise and will mark another

chapter in the evolution of Jamnagar. Unlike the earlier changes, which essentially involved ramping up scale of a well-established set of operations, HEAD OFFICE : Span Centre, 2nd Floor, Ramakrishana Mission Road, Santacruz(West), Mumbai - 400 054, INDIA.

this will require management of seemingly disparate business, each with its own growth drivers and challenges. Not all of the technologies that Tel : +91-22-66802222 / 26045601 E-Mail : info@chemetindia.com Website: www.chemetindia.com

are to be deployed for the new energy businesses are commercially proven, and even for RIL this is unknown terrain. BRANCH OFFICES

Not emulated since AHMEDABAD OFFICE : 1101, Safal Prelude, HYDERABAD OFFICE : Flat No. 104, K1 Primo,

The lamentable side note to this impressive growth story is that it has not been emulated by others. For some time, it looked as if the 50-mtpa Corporate Road, Nr.Prahladnagar Garden, Kondapur X Roads, Hanuman Nagar, Kondapur,

refinery planned by the OMCs, first at Ratnagiri in Maharashtra, could do that. But the project became mired in the complex politics of the State. Anandnagar, Ahmedabad - 380 015, INDIA. Hyderabad-500 084, Telangana, INDIA.

Despite being able to rope in Saudi Aramco and ADNOC, the national oil companies (NOCs) of Saudi Arabia and Abu Dhabi, respectively, the Tel : +91-79-40370725 Tel : +91-40-4856 5970 / 71

project has made no headway. Nearly 10 years since it was first proposed even the location is yet to be finalised, and the NOCs have since plonked E-Mail : chemetahmedabad@chemetindia.com

significant monies on projects in China, where local and national authorities have rolled out the red carpet, and in their home countries. It remains NEW DELHI OFFICE : 214, Hans Bhavan, E-Mail : chemethyderabad@chemetindia.com

to be seen whether the election of a new government in Maharashtra, more in sync with the powers in Delhi, will mark a revival of this project. Wing No.1, Bahadurshah Zafer Marg, KOLKATA OFFICE : Sharma House, 3rd Floor, 1/2, Lord

New Delhi - 110 002, INDIA. Sinha Road, Kolkata - 700 071, INDIA.

Notwithstanding all the talk on green growth and decarbonisation, India will continue to need new refining capacity for several decades

to come, as it seeks to become more prosperous with a much larger emphasis on manufacturing. A large refinery, integrated downstream Tel : +91-11-45751865 Tel : +91-33-22827247 / 22826511

into petrochemicals, will afford fabulous opportunities to valorize many streams that come from a barrel of crude, and build a diversified E-Mail : chemetdelhi@chemetindia.com E-Mail : chemetkolkata@chemetindia.com

chemical industry. CHENNAI OFFICE : 8-J, Century Plaza, 560-562,

Anna Salai, Teynampet, Chennai - 600 018, INDIA.

Jamnagar has no parallels in India, but that needs to change. It must be emulated by others!

Tel : +91-44-24342245 / 24349301

Ravi Raghavan E-Mail : chemetchennai@chemetindia.com

132 Chemical Weekly January 7, 2025 Chemical Weekly January 7, 2025 133

Contents Index to Advertisers Index to Products Advertised