Page 155 - CW E-Magazine (19-8-2025)

P. 155

News from Abroad

REDUCING EMISSIONS

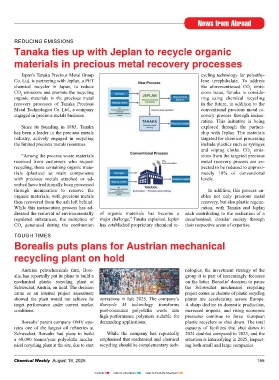

Tanaka ties up with Jeplan to recycle organic

materials in precious metal recovery processes

Japan’s Tanaka Precious Metal Group cycling technology for polyethy-

Co. Ltd. is partnering with Jeplan, a PET lene terephthalate. To address

chemical recycler in Japan, to reduce the aforementioned CO emis-

2

CO emissions and promote the recycling sions issue, Tanaka is conside-

2

organic materials in the precious metal ring using chemical recycling

recovery processes of Tanaka Precious in the future, in addition to the

Metal Technologies Co. Ltd., a company conventional precious metal re-

engaged in precious metals business. covery process through incine-

ration. This initiative is being

Since its founding in 1885, Tanaka explored through the partner-

has been a leader in the precious metals ship with Jeplan. The materials

industry, actively engaged in recycling targeted for chemical processing

the limited precious metals resources. include plastics such as syringes

and wiping cloths. CO emis-

2

“Among the process waste materials sions from the targeted precious

received from customers who request metal recovery process are ex-

recycling, those containing organic mate- pected to be reduced to approxi-

rials (plastics) as main components mately 10% of conventional

with precious metals attached or ad- levels.

sorbed have traditionally been processed

through incineration to remove the In addition, this process en-

organic materials, with precious metals ables not only precious metal

then recovered from the ash left behind. recovery, but also plastic regene-

While this incineration process has ad- ration, with Tanaka and Jeplan

dressed the removal of environmentally of organic materials has become a each contributing to the realisation of a

regulated substances, the reduction of major challenge,” Tanaka explained. Jeplan decarbonised, circular society through

CO generated during the combustion has established proprietary chemical re- their respective areas of expertise.

2

TOUGH TIMES

Borealis puts plans for Austrian mechanical

recycling plant on hold

Austrian petrochemicals firm, Bore- nologies, the investment strategy of the

alis, has reportedly put its plans to build a group it is part of increasingly focusses

mechanical plastic recycling plant at on the latter. Borealis’ decision to pause

Schwechat, Austria, on hold. The decision the Schwechat mechanical recycling

came as an internal project assessment project comes as closures of plastic recycling

showed the plant would not achieve its operations in late 2025. The company’s plants are accelerating across Europe.

target performance under current market Borcycle M technology transforms A sharp decline in domestic production,

conditions. post-consumer polyolefin waste into increased imports, and rising economic

high-performance polymers suitable for pressures continue to force European

Borealis’ parent company OMV ope- demanding applications. plastic recyclers to shut down. The total

rates one of the largest oil refineries at capacity of facilities that shut down in

Schwechat. Borealis had plans to build While the company has repeatedly 2024 doubled compared to 2023, and the

a 60,000 tonnes/year polyolefin mecha- emphasised that mechanical and chemical situation is intensifying in 2025, impact-

nical recycling plant at the site, due to start recycling should be complementary tech- ing both small and large companies.

Chemical Weekly August 19, 2025 155

Contents Index to Advertisers Index to Products Advertised