Page 193 - CW E-Magazine (22-4-2025)

P. 193

Special Report

Process safety and risk management (Part 6): Risk

management and sustainable operations

Everything that can be counted tion to tolerable level. The committee JOY M. SHAH

does not necessarily count; every- is linked to various site sub-committees Founder and Chief Consultant

“thing that counts cannot necessa- for ease of communication and execu- Innov8 ProTech Solutions

rily be counted.Albert Einstein tion of action plan. One of the respon- Former Sr. Vice President – Technical

sibilities of this committee is safety Reliance Industries Ltd.

This is the last paper in this series of and operational risk, which shall be E-mail: joymshah@gmail.com

Process Safety and Risk Management addressed in this article. acceptable level. We have discussed

in which I have addressed most critical many methods of Hazards and Risk

areas for achieving safe and sustainable Risk Management is vast subject Analysis in Part 4 (Process hazards

operation. Chemical and hydrocarbon and I shall try to give a brief outline of analysis and facility siting).

manufacturing facilities are high haz- the same.

ards locations and in short, every acti- Risk assessment

vity carries risk. The risk can be limited Defi nition of Risk Risk taking is fundamental to busi-

to the boundary of the organisation or In simple term, Risk is an uncer- ness, and exposure to risk is essential

may extend beyond boundaries and can tain future event that if it occurs, will to gain economic profi t.The challenge

not only damage assets and reputation impact the sustainability of operation is to recognize which risks differen-

but can wipe off organisation. and safety of people. It is defi ned as tially impact safe and sustainable ope-

a function of probability of occurrence rations. For sustainable operations of

In order to assess BusinessRisk and of any incident and consequence of the any high hazards plant, following seven

reduce it to tolerable level, one of the incident. Every organisation has criteria elements are considered for risk assess-

board member of any such organisation of classifying the risk into acceptable ment of manufacturing operations:

must be a risk expert chairing the Busi- and non-acceptable level. The risk can 1. Personal safety

ness Risk and Assurance Committee to be reduced by providing safeguards. 2. Process safety

discuss and assess risks, assign owners Therefore, by additional safeguard, 3. Health and industrial hygiene

to the risk, and facilitate risk reduc- Special Article 4 (22.04.2025)

non-acceptable risk can be brought to 4. Security

*Security risks, Natural Calamities, Pandemic, etc.

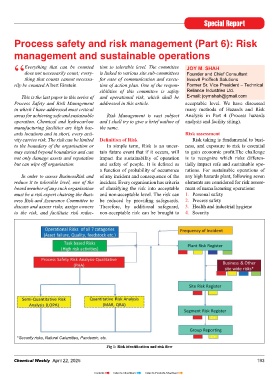

Fig 1: Risk identification and risk flow Fig 1: Risk identifi cation and risk fl ow

2. Evaluate incident outcomes based on energy released, material released, downwind vapour

Chemical Weekly April 22, 2025 193

concentration, radiant heat flux, or explosion overpressure. Assess requirement of dispersion analysis

or simulation of incident to identify area of impact.

Contents

Index to Advertisers

Index to Products Advertised

3. Estimate impact of incident on plant, people, and profit as well as environment and number of

individuals affected within site and beyond site.

4. Estimate the potential incident frequencies based on generic data within site or similar incident that

happened other locations, other countries.

5. Estimate the risk by combiningconsequence with event frequency.

6. Identify sources of risk, analyse the system and determine if there are cost-effective addition of barrier

in terms of process or modifications which can reduce risk.

7. Again, evaluate risk against required risk criteria.

8. If the risk is considered to be excessive, identify and prioritise risk reduction measures and inform site

and board level committee.

Criteria for acceptability of risk

We are concerned with loss prevention,sustainability of operation and safety of plant personnel & public.

Criteria of acceptability of risk are clearly required for each main area of risk,viz:

1. Loss to plant equipment;

2. Lossof employee lives;

3. Loss to environment; and

4. Loss to general public.

Convert all these to overall business loss for each risk criteria and define it as a tolerable or intolerable risk.

Consider both direct and indirect losses.

Alternatively, prepare Risk Assessment Matrix (RAM) as given below and position incident in the right block.

Benefits and drawbacks of RAM are as follows:

1. It enables consistent approach to qualitative risk assessment; and

2. It establishes a common terminology to support communication about risk.

RAM is to usedin accordance with certain fundamental principles:

3. It refers only to the specific risks to determine how to categorise; and

4. It does not generate decision about actions that should be taken.

No two companies have the same risk tolerance, and every company must develop their own based on their

business tolerance. Experts can help develop such matrix based on risk tolerance capabilities.

2