Page 198 - CW E-Magazine (12-11-2024)

P. 198

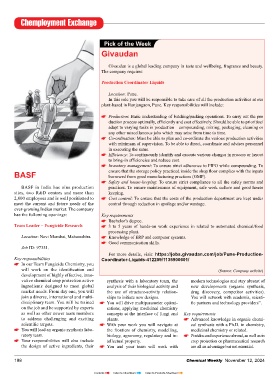

Chemployment Exchange Chemployment Exchange

Good English language skills. For more details, visit: https://basf. Diploma in Industrial Safety.

Creativity, curiosity and enthusiasm to jobs/light_blue_AP/job/Dahej-Assis- More than 5 years’ experience in similar

Givaudan drive innovations. tant-Manager-Production/973176601/ chemical industries.

Interpersonal and communication skills At least 3-5 years in handling plant

to develop innovative solutions in a Assistant Manager – Process Safety safety.

Givaudan is a global leading company in taste and wellbeing, fragrance and beauty. diverse team. Knowledge on legal compliance w.r.t.

The company requires: safety as per the Factories Act, etc.

For more details, visit: https://basf. Location: Thane, Maharashtra.

Production Coordinator Liquids jobs/light_blue_AP/job/Team-Leader- For more details, visit: https://basf.

Fungicide-research/1050403501/ Objectives of the position jobs/light_blue_AP/job/Assistant-

Location: Pune. To lead process safety risk management Manager-Process-Safety/1086762301/

In this role you will be responsible to take care of all the production activities at our Assistant Manager – Production activities at site and develop PSRM

plant-based in Ranjangaon, Pune. Key responsibilities will include: practices across the site are consistently (Source: Company website)

Location: Dahej, Gujarat. applied and sustainable.

Production: Basic understanding of batching/packing operations. To carry out the pro Job ID: 86242. To drive process safety risk reduction Lonza

for new plants or establish new projects

duction process optimally, effi ciently and cost effectively. Should be able to prioritise/

adapt to varying tasks in production – compounding, mixing, packaging, cleaning or Objectives of the position: Responsibi- for existing plants. Lonza, a global leader in life sciences

any other miscellaneous jobs which may arise from time to time. lity of technical, quality and cost-effective Ensuring compliances applicable to operating across three continents, requires:

Co-ordination: Must be able to plan and co-ordinate the various production activities manufacturing of dispersions operations. It EHS statutory requirements.

with minimum of supervision. To be able to direct, coordinate and advises personnel also involves plant and process safety, health Liaising with local regulatory agencies. Head – Environmental Health & Safety

in executing the same. and environmental activities related to the Implementation of process safety man- (EHS)

Effi ciency: To continuously identify and execute various changes in process or layout plant and personnel working in the plant. agement system requirements.

to bring-in effi ciencies and reduce cost. Location: Haryana.

Inventory management: To ensure strict adherence to FIFO while compounding. To Key responsibilities Core responsibilities

Propose and lead systematic improve-

BASF ensure that the storage policy practiced inside the shop fl oor complies with the inputs Coordinate and manage production in ments in operation safety system Reference: R62914.

borrowed from good manufacturing practices (GMP).

shift with consistent quality as per the

Safety and house-keeping: To ensure strict compliance to all the safety norms and target. and emergency management through Key responsibilities

BASF in India has nine production practices. To ensure maintenance of equipment, safe work culture and good house Continuous improvement of processes design safety reviews and HAZOP/ To ensure EHS & Security management

sites, two R&D centres and more than keeping. in coordination with the Head – Disper- hazard study reviews. system implementation in organisation.

2,000 employees and is well positioned to Cost control: To ensure that the costs of the production department are kept under sions Plant & Quality Control to reduce To develop and maintain systems for To ensure compliance of local regula-

meet the current and future needs of the control through reduction in spoilage and/or wastage. batch cycle times, increase in yields, monitoring and reporting process safety tion.

ever-growing Indian market. The company increase operational ease and ultimately performance indicators (PSPI) and use To ensure operation/maintenance of

has the following openings: Key requirements leading to cost effective production. these to drive performance improve- WWTP & fi re safety systems.

Bachelor’s degree. Guiding group of offi cers/operators in ments. Responsible for ensuring that the global

Team Leader – Fungicide Research 3 to 5 years of hands-on work experience in related to automated chemical/food the plant continuously to ensure product To ensure that process safety aspects EHS philosophy is translated into the

processing plant. quality of international standard. are identifi ed and assessed through the India operations.

Location: Navi Mumbai, Maharashtra. Knowledge of ERP and computer systems. Implement Safety, Health and Environ- management of change process includ- Responsible for supporting site/line

Good communication skills. ment system of the plant concerning ing direct involvement/leading required management and employees in defi n-

Job ID: 97351. man and equipment. hazard studies. ing, understanding and meeting their

For more details, visit: https://jobs.givaudan.com/job/Pune-Production- Update knowledge regarding product & To carry out process safety audits and EHS&S responsibilities.

Key responsibilities Coordinator-Liquids-412209/1135900601/ technology through proper channel. safety conversations at the site and Ensure that all safety equipment within

In our Team Fungicide Chemistry, you Ensuring proper maintenance of all the establish a system of routine process the company is as working condition,

will work on the identifi cation and (Source: Company website) norms as per the departmental operating safety audits. and serviced at regular intervals, etc.

development of highly effective, inno- procedures of ISO 9001, ISO 14001 & ISO. Develop process safety competency

vative chemical crop protection active synthesis with a laboratory team, the modern technologies and stay abreast of Compliance to process safety and envi- among team and make team aware of Key requirements

ingredients designed to meet global analysis of their biological activity and new developments (organic synthesis, ronmental protection code as per BASF relevant engineering standards to effec- Diploma/Advance Diploma in Industrial

market needs. From day one, you will the use of structure-activity relation- drug discovery, competitor activities). practice. tively manage process safety. Health Safety/Degree in Engineering/

join a diverse, international and multi- ships to initiate new designs. You will network with academia, scienti- Ensure the documentation of Respon- Maintain plant inspection records and Master Degree (Preferred) with mini-

disciplinary team. You will be trained You will drive multiparameter optimi- fi c partners and technology providers”. sible Care requirement on continual act on the fi ndings in collaboration with mum 15 years of relevant experience.

on the job and be supported by experts sations, applying medicinal chemistry basis, etc. the plant engineer and plant supervisor. Certifi cation: Safety Diploma/Safety

as well as other newer team members concepts at the interface of fungi and Key requirements Coordinate and review all the quality Certifi cate course in EHS (optional).

to address challenging and exciting plants. Advanced knowledge in organic chemi- Key requirements documentation and records, etc. Excellent communication skills, etc.

scientifi c targets. With your work you will navigate at cal synthesis with a Ph.D. in chemistry, Education: Bachelor’s degree in Chemi-

You will lead an organic synthesis labo- the frontiers of chemistry, modelling, medicinal chemistry or related. cal Engineering. Key requirements For more details, visit: https://www.

ratory team. biology, agronomy, regulatory and in- Postdoc and experience abroad, as well as in Experience: 3-10 years. Bachelor of Chemical Engineering with lonza.com/jobs/R62914

Your responsibilities will also include tellectual property. crop protection or pharmaceutical research Technical & professional knowledge: experience as a process engineer, opera-

the design of active ingredients, their You and your team will work with are all an advantage but not essential. Chemical Process. tions engineer, or process safety engineer. (Source: Company website)

198 Chemical Weekly November 12, 2024 Chemical Weekly November 12, 2024 199

Contents Index to Advertisers Index to Products Advertised