Page 153 - CW E-Magazine (27-5-2025)

P. 153

Special Report

A rapid wrap-up of what’s new in Operations,

Processes and Products

Catalytic Processes

catalyst. Aspects of catalyst deactiva-

tion are also covered (could be from impu-

rities in paraformaldehyde). POMDMEs

are reported to be a good additive for

diesel to reduce pollution. (Chem. Eng.

Sci., 2025, 306, 1 March, 121216;

DOI: 10.1016/j.ces.2025.121216).

Modifi ed oxymethylene

dimethyl ethers (OMEs) based

on technical alcohol mixtures

and their fuel properties

[This column has covered work on

OMEs based on methanol and HCHO.]

Green synthesis of tert-butyl Di-tert-butyl peroxide is also formed.

hydroperoxide (TBHPO) via The above reactor has many advan- V.Z. Francesconi et al have come out

oxidation of tert-butanol (B) in tages. (J. Chem. Technol. Biotechnol., with the title ethers based on mixed

alcohols which may come from fer-

various reactors 2025; DOI: 10.1002/jctb.7821). mentation or via oxo processes. Thus

A. Shiue et al have used H SO by the Reaction of CH OH with C-4-alcohol isomer mixtures were

4

2

3

green and environmentally-friendly HCHO as paraformaldehyde studied, and these products can be used

H O as oxidant, and micro-channel to make polyoxymethylene as neat fuel or as blending component

2

2

reactor, Corning Advanced-Flow, was dimethyl ethers (POMDMEs) for fossil or paraffi nic diesel fuels. The

used. The reaction temperature was reactions are catalysed in some way as

70°C and the optimal molar ratio of B to X. Wang et al have studied the kinetics with CH OH + HCHO.

3

H SO was assessed as 1:1 and the opti- of the title reaction in a fi xed-bed reac-

2

4

mum molar ratio of H O to B was 0:8. tor using cation ion exchange resin as Performance of Fe-Mo

2 2

catalysts with Li/Na/K

promoters for methanol

oxidation to HCHO

The production of HCHO via cata-

lytic oxidation of methanol is widely

practiced and Fe-Mo catalysts are

employed. J. Li et al have studied the

role of Li/Na/K as promoters for the

above catalysts. This study investigates

the infl uence of the above alkali metal

on the morphology, structure, surface

properties, and catalytic performance

of Fe-Mo catalysts. The detailed varia-

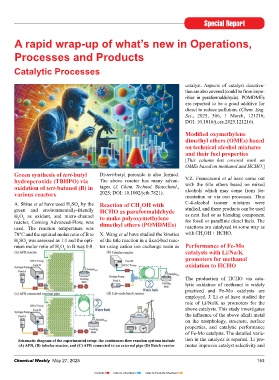

Schematic diagram of the experimental setup: the continuous fl ow reaction systems include tion in the catalysts is reported. Li pro-

(A) AFR, (B) tubular reactor, and (C) AFR connected to an external pipe (D) Batch reactor moter improves catalyst selectivity and

Chemical Weekly May 27, 2025 153

Contents Index to Advertisers Index to Products Advertised