Page 144 - CW E-Magazine (7-5-2024)

P. 144

Top Stories

BROWNFIELD EXPANSION

Himadri to ramp up capacity for speciality carbon

black

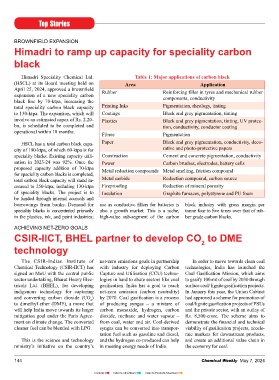

Himadri Speciality Chemical Ltd. Table 1: Major applications of carbon black

(HSCL) at its Board meeting held on Area Application

April 25, 2024, approved a brownfi eld Rubber Reinforcing fi ller in tyres and mechanical rubber

expansion of a new speciality carbon components, conductivity

black line by 70-ktpa, increasing the

total speciality carbon black capacity Printing Inks Pigmentation, rheology, tinting

to 130-ktpa. The expansion, which will Coatings Black and grey pigmentation, tinting

involve an estimated capex of Rs. 2.20- Plastics Black and grey pigmentation, tinting, UV protec-

bn, is scheduled to be completed and tion, conductivity, conductor coating

operational within 18 months. Fibres Pigmentation

HSCL has a total carbon black capa- Paper Black and grey pigmentation, conductivity, deco-

city of 180-ktpa, of which 60-ktpa is for rative and photo-protective papers

speciality blacks. Existing capacity utili- Construction Cement and concrete pigmentation, conductivity

sation in 2023-24 was 92%. Once the Power Carbon brushes, electrodes, battery cells

proposed capacity addition of 70-ktpa Metal reduction compounds Metal smelting, friction compound

for speciality carbon blacks is completed,

total carbon black capacity will stand in- Metal carbide Reduction compound, carbon source

creased to 250-ktpa, including 130-ktpa Fireproofi ng Reduction of mineral porosity

of speciality blacks. The project is to Insulation Graphite furnaces, polystyrene and PU foam

be funded through internal accruals and

borrowings from banks. Demand for use as conductive fi llers for batteries is black industry with gross margin per

speciality blacks is concentrated primarily also a growth market. This is a niche, tonne four to fi ve times over that of rub-

in the plastics, ink, and paint industries; high-value sub-segment of the carbon ber grade carbon blacks.

ACHIEVING NET-ZERO GOALS

CSIR-IICT, BHEL partner to develop CO to DME

2

technology

The CSIR-Indian Institute of net-zero emissions goals in partnership In order to move towards clean coal

Chemical Technology (CSIR-IICT) has with industry for deploying Carbon technologies, India has launched the

signed an MoU with the central public Capture and Utilisation (CCU) techno- Coal Gasifi cation Mission, which aims

sector undertaking, Bharat Heavy Elec- logies in hard to abate sectors like coal to gasify 100-mt of coal by 2030 through

tricals Ltd. (BHEL), for developing gasifi cation. India has a goal to reach surface coal/ lignite gasifi cation projects.

indigenous technology for capturing net-zero emission (carbon neutrality) In January this year, the Union Cabinet

and converting carbon dioxide (CO ) by 2070. Coal gasifi cation is a process had approved a scheme for promotion of

2

to dimethyl ether (DME), a move that of producing syngas – a mixture of coal/lignite gasifi cation projects of PSUs

will help India move towards its larger carbon monoxide, hydrogen, carbon and the private sector, with an outlay of

mitigation goal under the Paris Agree- dioxide, methane and water vapour – Rs. 8,500-crore. The scheme aims to

ment on climate change. The converted from coal, water and air. Coal-derived demonstrate the fi nancial and technical

cleaner fuel can be blended with LPG. syngas can be converted into transpor- viability of gasifi cation projects, accele-

tation fuel such as gasoline and diesel, rate markets for downstream products,

This is the science and technology and the hydrogen co-produced can help and create an additional value chain in

ministry’s initiative on the country’s in meeting energy needs of India. the economy for coal.

144 Chemical Weekly May 7, 2024

Contents Index to Advertisers Index to Products Advertised