Page 181 - CW E-Magazine (16-1-2024)

P. 181

Special Report Special Report

Designed enzymatic polysaccharides: Diversifi cation of existing beet or cane sugar processing

to further expand the bio-circular economy.

opportunity for a sugar biorefi nery For example, attractive for the inte-

gration of the enzymatic polymerisation

his case study describes the Cli- process within a beet sugar biorefi nery

mate Change Potential (CCP) im- is the fact that sucrose process streams

Tpacts of biomaterials derived from are directly converted into the polysac-

enzymatic polymerisation, an emerging Laundry & Personal Nonowovens charide and a co-product fructose stream.

care

Homecare

platform technology for the biorefi nery This process is 100% carbon effi cient; no

Enzymatic

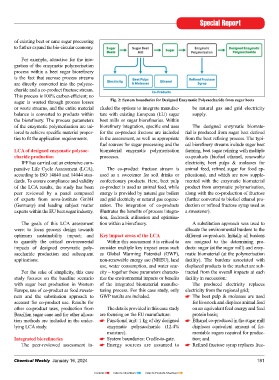

integrated conversion of beet sugar to Cane Sugar Polymerisation sugar is wasted through process losses Fig. 2: System boundaries for Designed Enzymatic Polysaccharide from sugar beets

Beet &

biomaterials. Packaging Footware Composites or waste streams, and the entire material cluded the options to integrate manufac- be natural gas and grid electricity

& Textiles balance is converted to products within ture with existing European (EU) sugar supply.

The platform technology has been the biorefi nery. The process parameters beet mills or sugar biorefi neries. Within

developed by International Flavors and Biofuel Sweetener of the enzymatic polymerisation are tai- biorefi nery integration, specifi c end uses The designed enzymatic biomate-

Fragrances (IFF), a leader in food, beve- lored to achieve specifi c material proper- for the co-product fructose are included rial is produced from sugar beet derived

rage, health, biosciences, home & per- Fig. 1: Designed Enzymatic Biomaterials ties to fi t the application requirements. in the assessment, as well as appropriate from the beet refi ning process. The typi-

sonal care and sensorial experiences. substance constituting all biomass. For accessible at industrial scale. These fuel sources for sugar processing and the cal biorefi nery streams include sugar beet

example, cellulose or starch are polysac- designed polysaccharides have the consis- LCA of designed enzymatic polysac- biomaterial enzymatic polymerisation farming, beet sugar refi ning with multiple

Enzymatic polymerisation – The charides – both part of the family of poly- tency required for typical industrial and charide production processes. co-products (biofuel ethanol, renewable

technology sugars – and are built from simple sugars. consumer applications (Figure 1). IFF has carried out an extensive com- electricity, beet pulps & molasses for

In nature, enzymes within plants This enzymatic polymerisation process parative Life Cycle Assessment (LCA), The co-product fructose stream is animal feed, refi ned sugar for food ap-

connect together simple sugars, pro- will enable access to polysaccharides Specifi cally, the process integrates according to ISO 14040 and 14044 stan- used as a sweetener for soft drinks or plications), and which are now supple-

ducts of photosynthesis, into the material which are found in nature, but are now directly into existing sugar beet or sugar dards. To ensure compliance and validity confectionary products. Here, beet pulp mented with the enzymatic biomaterial

cane biorefi neries and converts sugars of the LCA results, the study has been co-product is used as animal feed, while product from enzymatic polymerisation,

into polysaccharides, which fi nd applica- peer reviewed by a panel composed energy is provided by natural gas boilers along with the co-production of fructose

tions across a series of end-use markets of experts from nova-Institute GmbH and grid electricity or natural gas cogene- (further converted to biofuel ethanol pro-

typically replacing fossil-based incum- (Germany) and leading subject matter ration. The integration of co-products duction or refi ned fructose syrup used as

bent materials. Polysaccharides derived experts within the EU beet sugar industry. illustrates the benefi ts of process integra- a sweetener).

from this bioprocess are not only renew- tion, feedstock utilisation and optimisa-

ably sourced, but also readily biodegrad- The goals of this LCA assessment tion within a biorefi nery. A substitution approach was used to

able, which is often a desired end-of-life were: to focus process design towards allocate the environmental burdens to the

characteristic. optimum sustainability impact; and Key impact areas of the LCA different co-products. Initially all burdens

to quantify the critical environmental Within this assessment it is critical to are assigned to the determining pro-

Either sugarcane or sugar beet can be impacts of designed enzymatic poly- consider multiple key impact areas such ducts: sugar (at the sugar mill) and enzy-

the feedstock for this process technology, saccharide production and subsequent as Global Warming Potential (GWP), matic biomaterial (at the polymerisation

both of which are globally available and applications. non-renewable energy use (NREU), land facility). The burdens associated with

fully fungible feedstocks produced within use, water consumption, and water scar- displaced products in the market are sub-

biorefi neries operating and accessible at For the sake of simplicity, this case city – together these parameters characte- tracted from the overall impacts at each

scale. Compared to agricultural crops study focuses on the baseline scenario rize the environmental impacts or benefi ts facility in succession:

farmed globally, both sugar beet and sugar with sugar beet production in Western of the integrated biomaterial manufac- The produced electricity replaces

cane already provide leading land-use Europe, use of co-product as food sweete- turing process. For this case study, only electricity from the regional grid;

effi ciency with regard to biomass yield ners and the substitution approach to GWP results are included. The beet pulp & molasses are used

per hectare land. Sugar beet for example, account for co-product use. Results for for livestock and displace animal feed

as annual, multi-use rotational crop, has other co-product uses, production from The details provided in this case study on an equivalent feed energy and feed

proven sustainable and continuous pro- Brazilian sugar cane and for other alloca- are focusing on the EU manufacture: protein basis;

ductivity and yield improvement through tion methods are included in the under- Functional unit: 1 kg of dry designed Ethanol co-produced in the sugar mill

decades. This emerging biomaterial plat- lying LCA study. enzymatic polysaccharide (12.4% displaces equivalent amount of fer-

form technology connects directly sus- moisture). mentable sugars required for produc-

*Depending on the industry and application-specifi c DEB-based tainable agriculture within rural commu- Integrated biorefi neries System boundaries: Cradle-to-gate. tion; and

product formulation and certifi cation requirements.

nities with the biorefi nery infrastructure The peer-reviewed assessment in- Energy sources are assumed to Refi ned fructose syrup replaces fruc-

180 Chemical Weekly January 16, 2024 Chemical Weekly January 16, 2024 181

Contents Index to Advertisers Index to Products Advertised