Page 176 - CW E-Magazine (11-2-2025)

P. 176

Special Report Special Report

membranes, which exhibited long-

term stability under 9 bar and 50°C. Biochar – a sustainable fuel

The recovery rate was over 84% and

C H purity was over 97.5%, which ince the time our ancestor Homo agency representatives, etc., acknow- A.K. DAS

3

6

met the requirements of the process. erectus invented and learned to ledged a common interest to promote Retd. Industrial Adviser

(J. Membrane. Sci., 2024, 708, August, Scontrol fi re during the early Stone research, development, demonstration, Dept. of Chemicals & Petrochemicals

123056; DOI:10.1016/j.memsci.2024. Age, biomass was being used as the only deployment (RDD&D) and commercia- Govt. of India

123056). source of energy. Even now, biomass – lisation of the technology of biochar Email: amiyakantidas2010@gmail.com

cow dung, agricultural wastes, wood production.

Using Porous Liquids (PLs) etc. – is used as a reliable energy source the reduction zone and 800-1000°C in

to perform liquid-liquid and provides about one-third of primary Biochar is lightweight black rem- the combustion zone. The specifi c yield

separation energy consumed by the developing nants, consisting of carbon and ashes, from pyrolysis is dependent on pro-

world, including rural India. Globally, remaining after pyrolysis of biomass, cess parameters such as temperature,

2-

B. Lai et al have referred to PLs as new PL3 (Silicalite-1@PDMS) demonstra- (SiF ) anions and a small pore size were it isestimated that one-seventh of the and is a form of charcoal. The word heating rate and residence time. Tem-

6

types of fluid sorbent for separation of ted effectiveness in achieving selective devised for the above separation. In situ primary energy consumed in the world “biochar” is a late 20th century Eng- perature range of 400-500°C produces

gas mixtures. These author have now alcohol extraction from beverages IR spectroscopy was developed. There is derived directly from biomass. lish neologism derived from the Greek more char, whereas temperature above

adopted PLs for the separation of mis- (e.g., gin/wine). [This strategy merits was preferential adsorption of C H . (Ind. word bios, “life” and “char” ( charcoal 700°C favours the yield of liquid and

2

2

cible liquids MEG/water and ethanol/ further attention.] (Angew. Chem. Eng. Chem. Res., 2024,DOI:10.1021/ In India, industrial units in rice produced by carbonisation of bio- gas fuel components. Typical yields

water as proof of principle. PLs ZIF-8@ Intl. Ed., 2024; DOI: 10.1002/anie. acs.iecr.4C01748). producing areas use rice husk as a mass). It is recognised as charcoal that are 60% bio-oil, 20% biochar and 20%

PDMS (PL1, PDMS = polydimethyl 202409694). source of energy. Sugar mills also participates in biological processes syngas. For typical inputs, the energy

silicone) or ZIF-8@sesame oil (PL2), Tailored postsynthetic meet their thermal energy needs by found in soil, aquatic habitats and in required to run a “fast” pyrolyser is

each consisting of 25 wt % of hydro- Separation of acetylene/ nitration of a hyper burning bagasse. Where cogeneration animal digestive systems. approximately 15% of the output.

phobic material ZIF-8 dispersed in ethylene crosslinked polymer for facility has been installed, this meets

PDMS/sesame oil were formulated and [This separation is involved in naphtha/ single-step C H purification the in-house electricity demand and Production methods Production temperature infl uences

4

2

found to be exceedingly physically sta- ethane crackers for olefins/ethylene and from a ternary C gas mixture surplus electricity is added to the The process of making biochar is biochar properties in several ways. The

ble. A 5-nm PEEK membrane was used usually selective hydrogenation of C H 2 national grid or sold to customers. an ancient practice said to imitate the molecular carbon structure of the solid

2

2

to provide permeable barrier between to C H is done and selective absorption S.M. Lee et al have worked on the title Over the years, variants from biomass earth’s natural cycle. It locks away biochar matrix is particularly affected.

4

2

in polar solvents is also practiced (e.g., purification from a ternary C H /C H / have been developed for domestic and carbon instead of releasing it and has Initial pyrolysis at 450-550°Cleaves an

2

2

4

2

in Nagothane in Maharashtra).] C H mixture. The title porous organic industrial use. been recognised as a form of carbon amorphous carbon structure, whereas

2

6

polymer (HCP) was made resulting sequestering by the UN International temperature above this range will re-

Y-Y. Xiong et al have worked on this in HCP-NO -1 and HCP-NO -2 with What is biochar? Panel on Climate Change. Carbon sult in the progressive thermochemical

2

2

separation through cation exchange in an different nitration degrees. This HCP- Biochar is a carbon-rich mate- dioxide (CO ) is the most commonly conversion of amorphous carbon into

2

anion-pillored hybrid ultramicroporous NO -1 gave selective separation of rial produced by pyrolysis – a process producedgreenhouse gas. Carbon turbostatic graphene sheets.

2

MOF. Two hybrid ultramicroporous C H from C H /C H /C H mixture. that thermally decomposes biomass sequestration is the process of capturing

2

2

2

6

2

4

2

4

materials, LIFM-107 (Cu/Ni), featur- [Chem. Sus. Chem., 2024; DOI: 10.1002/ (such as agricultural wastes, wood and and storing atmospheric CO . It is one of Small scale methods

2

ing functionalised hexfluorosilicate CSSC.202400595). other organic materials) in absence of the methods of reducing the amount of Smallholding farmers in developing

oxygen, preventing combustion. This CO in the atmosphere with the goal of countries easily produce biochar with-

2

produces a mixture of solids (biochar), reducing global climate change. out special equipment. They make piles

liquid (bio-oil) and gas (syngas). Bio- of crop waste (e.g., maize stalks, rice

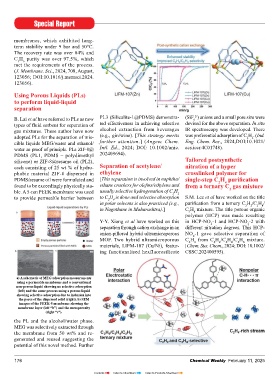

a) A schematic of MEG adsorption measurements char has been defi ned by International It has been reported that pre- or wheat straw), light the piles on the

using a permeable membrane and a conventional Biochar Initiative (IBI) as the “solid Columbian Amazonians produced bio- top and quence the embers with dirt or

non-porous liquid showing no selective adsorption

(left) and the same process using a porous liquid material obtained from the thermo- char by smoldering agricultural waste water to get biochar. This method greatly

showing selective adsorption due to inclusion into chemical conversion of biomass in an (i.e., covering burning biomass with reduces smoke, compared to traditional

the pores of the dispersed solid (right). b) SEM

images of the PEEK-5 membrane showing the oxygen-limited environment.” soil) in pits or trenches. It is not known methods of burning crop waste. This

membrane layer (left “b”) and the mesoporosity if they intentionally or unknowingly method is known as the ‘top-down

(right “c”).

IBI was formed in July 2006 at the used biochar to enhance soil producti- burn’ or ‘conservation burn’.

the PL and the alcohol/water phase. World Soil Science Congress in Phila- vity.

MEG was selectively extracted through delphia. During the meeting individuals, Alternatively, more industrial meth-

the membrane from 50 wt% and re- representatives from academic In the US gasifi ers are the most used ods can be used on small scales, while

generated and reused suggesting the institutions, commercial ventures, in- method of producing biochar. Tempera- in a centralised system, biomass is

potential of this novel method. Further vestment bankers, NGOs, US federal tures during pyrolysis is 250-550°C in brought to a central plant for processing

176 Chemical Weekly February 11, 2025 Chemical Weekly February 11, 2025 177

Contents Index to Advertisers Index to Products Advertised