Page 168 - CW E-Magazine (27-2-2024)

P. 168

Special Report

Upgrading waste PET

PET to prepare glycolic acid

(GA) by engineering bimetallic

AuCu/CNT catalyst

[This column has covered several

papers on upgrading PET waste and new

approaches keep getting published.]

E. Zhen et al have reported a novel stra-

tegy to directly depolymerise PET into is important and it is essential to obtain by calcination. (Catalysis Today, 2023,

terephthalic acid (TPA) and GA, which very small and active Cu particles. In 424, 1 Dec., 113801: DOI: 10.1016/j.

st

shows significantly higher value than the case of Cu/ZrO the most critical cattod.2022.06.016).

2

conventional ethylene glycol (EG). The aspect is its specific surface area, and Continuous hydrogenation of

title catalyst, whose method of prepara- a highly Cu phase. Cu/ZrO was found

2

tion is reported, accomplishes this task. to be more active and the main pro- cinnamaldehyde (C): Gas-Liq-

Catalyst was rigorously characterised. duct was 1,6-hexanediol. (Catalysis To- uid-Liquid-Solid (GLLS)

In effect EG gets converted to GA. (J. day, 2023, 424, 1 Dec., 113843; DOI: helical coil reactor

st

Chem. Technol. Biotechnology, 2023; 10.1016/j.cattod.2022.07.011). M.Y. Khan et al have carried out this

DOI: 10.1002/jctb.7489). industrially important reaction in a multi-

Beta zeolite as an efficient

Hydrolytic depolymerisation catalyst for the synthesis of phase system for selective reduction to

cinnamyl alcohol. The catalyst was 5%

of PET into TPA and MEG diphenolic acid (DPA) from Pt/C. The addition of a second liquid

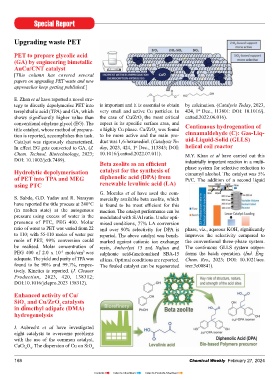

using PTC renewable levulinic acid (LA)

G. Morales et al have used the com-

S. Sabde, G.D. Yadav and R. Narayan mercially available beta zeolite, which

have reported the title process at 240°C is found to be most efficient for this

(in molten state) at the autogenous reaction. The catalyst performance can be

pressure using excess of water in the modulated with Si/Al ratio. Under opti-

presence of PTC, PEG 400. Molar mised conditions, 77% LA conversion

ratio of water to PET was varied from 22 and over 90% selectivity for DPA is phase, viz., aqueous KOH, significantly

to 110; with 55-110 moles of water per reported. The above catalyst was bench- improves the selectivity compared to

mole of PET, 99% conversion could marked against cationic ion exchange the conventional three-phase system.

be realised. Molar concentration of resin, Amberlyst 15 and Nafion and The continuous GLLS system outper-

PEG 400 of 2.0 x 10 mole/cm was sulphonic acid-functionalised SBA-15 forms the batch operation. (Ind. Eng.

-5

3

adequate. The yield and purity of TPA was silicas. Optimal conditions are reported. Chem. Res., 2023; DOI: 10.1021/acs.

found to be 90% and 99.1%, respec- The fouled catalyst can be regenerated iecr.3c00841).

tively. Kinetics is reported. (J. Cleaner

Production, 2023, 420, 138312;

DOI:10.1016/jclepro.2023 138312).

Enhanced activity of Cu/

SiO and Cu/ZrO catalysts

2

2

in dimethyl adipate (DMA)

hydrogenolysis

J. Aubrecht et al have investigated

eight catalysts to overcome problems

with the use of the common catalyst,

CuCr O . The dispersion of Cu on SiO

2 3 2

168 Chemical Weekly February 27, 2024

Contents Index to Advertisers Index to Products Advertised