Page 187 - CW E-Magazine (1-4-2025)

P. 187

Special Report

corrosion, and aid with CP by seg-

menting the pipeline.

The selection of the type of isola-

tion joint should be based on opera-

tional, installation, and maintenance

requirements. The distance between-

isolation joints or kits is a determin-

ing factor in corrosion protection

since extended distances might allow

current bridging from the unpro-

tected side of the isolation kit/joint

to the protected side.

Isolation gaskets

The choice of gasket material for

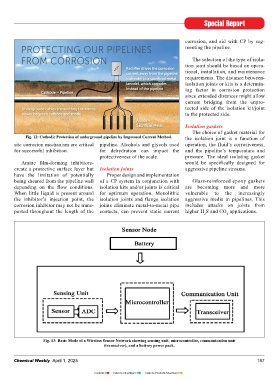

Fig. 12: cathodic Protection of underground pipeline by Impressed current Method. the isolation joint is a function of

site corrosion mechanism are critical pipeline. Alcohols and glycols used operation, the fluid’s corrosiveness,

for successful inhibition. for dehydration can impact the and the pipeline’s temperature and

protectiveness of the scale. pressure. The ideal isolating gasket

Amine film-forming inhibitors- would be specifically designed for

create a protective surface layer but Isolation joints aggressive pipeline streams.

have the limitation of potentially Proper design and implementation

being sheared from the pipeline wall of a CP system in conjunction with Glass-reinforced epoxy gaskets

depending on the flow conditions. isolation kits and/or joints is critical are becoming more and more

When little liquid is present around for optimum operation. Monolithic vulnerable to the increasingly

the inhibitor’s injection point, the isolation joints and flange isolation aggressive media in pipelines. This

corrosion inhibitor may not be trans- joints eliminate metal-to-metal pipe includes attacks on joints from

ported throughout the length of the contacts, can prevent static current higher H S and CO applications.

2

2

Fig. 13: Basic Mode of a Wireless Sensor network showing sensing unit, microcontroller, communication unit

(transceiver), and a battery power pack.

Chemical Weekly April 1, 2025 187

Contents Index to Advertisers Index to Products Advertised