Page 171 - CW E-Magazine (1-4-2025)

P. 171

Special Report

Process safety and risk management (Part 3):

Technical Model and Site Safety Leadership

Prepare and Prevent, don’t 2. Approving safety items and policies

Repair and Repent. The chain is of plant-wide nature. JOY M. SHAH

“only as long as the weakest link” – 3. Exchanging safety information Founder and Chief Consultant

Innov8 ProTech Solutions

Unknown. between plant and site areas. Former Sr. Vice President – Technical

Reliance Industries Ltd.

For Goal Zero incident, the system The CSC is supported by various sub- E-mail: joymshah@gmail.com

needs to be developed for clarity and committees addressing each element of

uniformity. As mentioned in above Process Safety and Behavioural Safety: report to CSC. Each committee consists

statements, if you do not prepare to 1. Process Hazards Analysis. of cross-functional team members from

prevent, you will repent. Again, if any of 2. Incident and injury investigations. Line Function. Each plant or group of

the links in the system is weak, incident 3. Pre-start up safety review. 2-3 plants can have one Safety Coordi-

cannot be zeroed down. Subject is vast; 4. Management of Change. nator. This is not Line Function and

therefore following article is only ready 5. Mechanical Integrity and Quality reports to CSC, whose role is:

reckoner for site leadership. Assurance. 1. Coordinate safety activities of plants

6. Contractor safety. and working of sub-committees.

To start with, I would like to con- 7. Process technology. 2. Participate in CSC.

sider following objectives for safety 8. Emergency planning and response. 3. Give advice on:

management system: 9. Safety Observation and Standard a. Training employees.

1. All accidents and injuries can be Operating Procedure. b. Offer training to supervisor of Line

prevented. 10. Operating Discipline and Recognition. Function.

2. Management is not only accountable 11. Training and capability development. c. Safety observation.

but responsible for preventing injuries. 12. Audit and assessment. d. Conduct and participate in Incident

3. Working safely must be the most Investigation.

important condition of employment Each plant or group of 2-3 plants can e. Ensure learning from incident is

and all line managers and supervisors have such dedicated committee who will reaching right employees.

have role to play.

4. All operating exposures can be safe-

guarded or avoided.

5. Training employees to work safely is

essential requirement for safety.

6. Prevention of personal injuries is

good business sense to improve triple

bottomline.

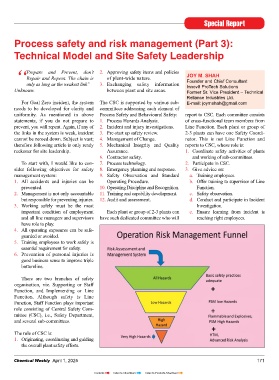

There are two branches of safety

organisation, viz. Supporting or Staff

Function, and Implementing or Line

Function. Although safety is Line

Function, Staff Function plays important

role consisting of Central Safety Com-

mittee (CSC), i.e., Safety Department,

and several sub-committees.

The role of CSC is:

1. Originating, coordinating and guiding

the overall plant safety efforts.

Chemical Weekly April 1, 2025 171

Contents Index to Advertisers Index to Products Advertised